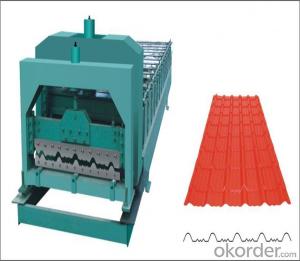

High Speed Trapezoidal sheets Roll Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Trapezoidal sheets Roll Forming Machine

Technical data of Trapezoidal sheets Roll Forming Machine

Suitable Material | Q235 color steel sheet;0.3-0.7mm, 1000&1250mm coil width | |

Working speed | About 20m/min | |

Power Requirement | Main motor power: 7.5 Kw(Depend on final design) | |

Hydraulic station power: 2.2Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 8500KGS | |

Machine''''s size | About 15m×1.8m× 1.5m (Depend on final design) | |

Shipping | 1x40GP container can load one machine | |

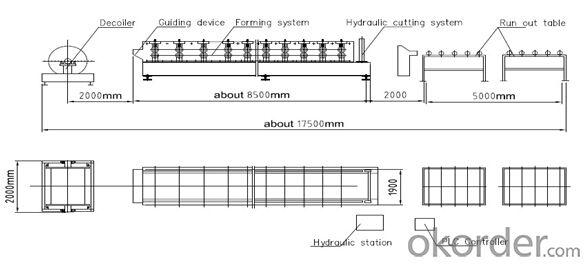

Layout drawing of Trapezoidal sheets roll forming machine

Our Trapezoidal sheets Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q: Say that China's machine is not good, then they are sold to whom?

- With the progress of society and the development of science and technology, the gap between domestic machine tools and imported machine tools will be getting smaller and smaller.

- Q: What is a CNC machine?

- ● can be multi-coordinate linkage, can process the shape of complex parts;

- Q: What is the main part of CNC machine tools?

- CNC machine work, do not need workers to directly operate the machine, to control the CNC machine tools,

- Q: What is rocker machine, gantry machine? Are these two types of machines belonging to the same classification method? Are there any other machine tools in this category?

- Various machine tools have a variety of machine tool classification methods, there is unity, but a variety of machine tools have a variety of machine tool classification.

- Q: The difference between the lathes 6140, 6240

- In the lathe can also be used drill, reaming drill, reamer, tap, die and knurling tools such as the corresponding processing.

- Q: What is the lathe?

- The driver must master the following basics:

- Q: What is the difference between CNC machine tools and general machine tools?

- 4, automatic tool changer CNC lathes are used automatic rotary turret, in the process of automatic tool change

- Q: What is the main work of CNC machine tools?

- , high precision machining 3, processing stable and reliable, to achieve computer control, excluding human error, parts of the processing of good consistency, stable and reliable quality.

- Q: Which machine is the leading machine

- The system is known as the "brain" of CNC machine tools, and accounts for more than 50% of the cost of CNC machine tools, is the world's only one of the three companies have this technology.

- Q: How is the system number defined in machine tool classification?

- According to the nature of processing and the use of knives: 12 categories

Send your message to us

High Speed Trapezoidal sheets Roll Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches