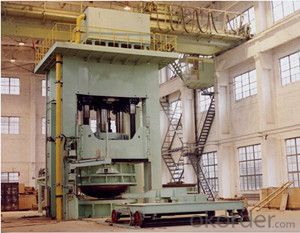

Forging Equipment Steel Pipe & Bar Straightening Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI’s steel pipe and bar straightening hydraulic presses are mainly used for straightening large-diameter pipes and bars. There are two structures, i.e. vertical straightening and horizontal straightening. We produce 5MN, 8MN, 10MN, 12.5MN, 20MN and 25MN models.

We also design and manufacture corresponding pipe and bar straightening hydraulic presses per customers’special requirements.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: Fenghua robot production of stamping robot, is fully automatic?

- According to their own products with manufacturers of solutions,

- Q: 16 punch stuck

- When the card mold, are in the bottom dead center, you can climb the flywheel with the flywheel to pull out the slider, the first empty back some, and then forced to Panxuanzhu plate (to the people standing direction), the general can be card

- Q: What is the relationship between the pressure of the punching machine and the air pressure?

- Mold pad pressure change value is generally 1.15 times

- Q: This manual punch is where the production

- Even the name is not, how to find ah, it is recommended to see which mechanical exhibition, a lot of this kind of thing

- Q: J23-16 stamping machine stuck how to solve?

- Or climbing rod into the flywheel wheel lever reverse wheel flywheel, forced to Panxuan rod plate (with the motor in the opposite direction of rotation), the card can generally solve the phenomenon.

- Q: There are several types of punching machine cylinder

- Cylinders have two types of reciprocating linear motion and reciprocating swing.

- Q: Who is invented?

- Function to more varieties of multi-standard integrated function development, from simple to today's delicate and beautiful, colorful

- Q: Punch 300mm wide 70mm thick 2mm 201 stainless steel plate how much tonnage punch

- Through the mold, can make blanking, punching, forming, drawing, finishing, fine red, plastic, riveting and extrusion, etc., are widely used in various fields.

- Q: How does this door's profile come out? The

- (5) facade to the level, not New Zealand;

- Q: How to calculate the tonnage of the punching machine

- Punch press calculation company P = kltГ

Send your message to us

Forging Equipment Steel Pipe & Bar Straightening Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords