Rock Wool Blanket and Board with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

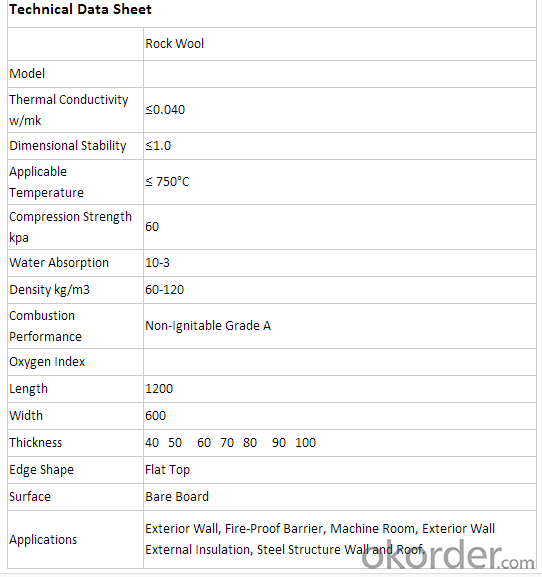

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q: Is it dangerous to make mineral cotton mattresses?

- You should see the mineral wool mattress, mineral wool is Lord palm mattress, adding mineral wool because of mineral materials with various physical properties under certain conditions, such as far infrared energy and electric energy, magnetic energy, new products, general quality products.

- Q: What are the building energy saving materials?

- Glass wool is second kinds of products of mineral wool, with silica sand, limestone, fluorite and other minerals as the main raw material, by melting method and centrifugal method, using flame or high energy gas blowing process, the molten glass liquid made of inorganic fiber. Glass wool products have good thermal insulation, heat insulation, sound absorption, non burning, corrosion resistance and other properties. They are widely used in building, piping, storage tanks, boilers, aircraft, ships and other parts of the insulation, heat insulation and sound absorption.

- Q: What are the composite thermal insulation boards?

- Polystyrene particle thermal insulation slurry, this kind of thermal insulation material water absorption rate is higher than other materials, use must do anti crack waterproof layer. Anti cracking and waterproof protective layer material is made up of anti cracking cement mortar and composite glass fiber net, which can effectively control the crack of protective layer for a long time

- Q: What's the difference between glass fiber and mineral wool?

- Melting natural rock or metallurgical slag in a cupola or a pool furnace, etc. by blowing or centrifuging.

- Q: What are the advantages of inorganic fiber spraying in construction engineering?

- The company has professional inorganic fiber spraying construction qualification, can undertake a variety of insulation works, the main products of the company are: a rigid polyurethane foam composite board, polyurethane hard foam coating, inorganic fiber coating, glass wool and rock wool board auxiliary materials. Professional undertake spraying level external wall thin plastering system thermal insulation project.

- Q: The difference between rock wool and mineral wool

- Originated in Hawaii. Rock wool products are high-quality basalt, dolomite as the main raw material, the high temperature above 1450 DEG after melting by four axis high speed centrifugal centrifuge international advanced fiber, and spray with a certain amount of binder, dustproof oil, water repellent cotton collector after collection, through the pendulum method, and three-dimensional method after cotton spreading curing, cutting, rock wool products form different specifications and applications.

- Q: The classification of exterior wall insulation and its main categories

- The first is the product standard, the complete expansion of polystyrene board external insulation board system, this system in our country now use probably accounted for more than 62%, some statistics in 80%, because the statistics are not accurate, but it is the highest market share, is also the most mature external insulation system.

- Q: What material is fast heated and kept warm?

- The gap between the heating tube and the aluminum tube is filled with a heat conductive insulating elastic rubber, so that the heat can be rapidly transferred to the aluminum tube.Conductive heat insulation elastic rubber adopts silicon rubber base material, boron nitride, alumina and other ceramic particles as filler, the heat conduction effect is very good. Under the same conditions, the thermal impedance is smaller than that of other thermal conductive materials. Having a soft, clean, no pollution, high insulation and radiation characteristics of glass fiber provides good mechanical properties to reinforcement, anti piercing, shear resistance, tear resistance, with conductive pressure-sensitive adhesive.

- Q: Why should the insulation board be spliced when it is installed?

- The EPS plate shall be bonded in a vertical arrangement and the vertical seam shall be staggered along the line. Insulation board construction fault seam stitching truth with brick walls are brick seam is a reason for strong security.

- Q: Is the calorimeter for building materials calorific value?

- Calorific value calorimeter for building materials is used to determine the calorific value of building combustible materials such as stone, wood, concrete, and even dispersed mineral wool and polymers.In the standard set / group under the condition of oxygen nitrogen calorimeter specimen is placed in a certain quality of a constant volume, in order to test the temperature rise test as the foundation, considering all the heat loss and latent heat of vaporization, heat of combustion calculation sample.

Send your message to us

Rock Wool Blanket and Board with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches