Rock Wool Insulation Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

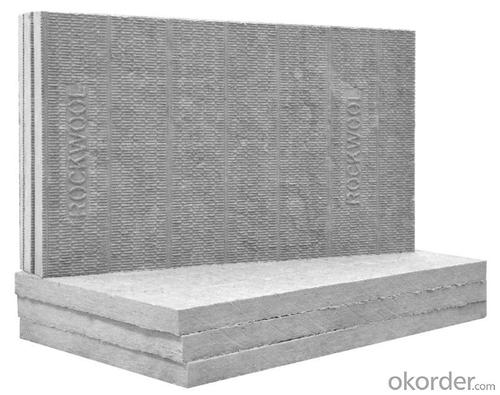

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

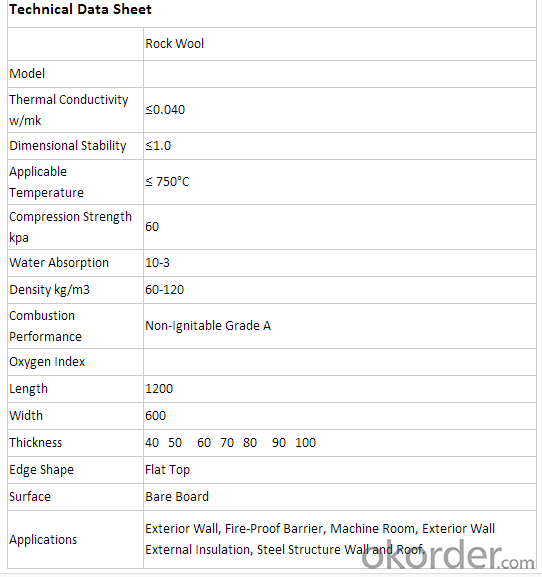

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q: What are the kinds of fire door core board?

- Organic thermal insulation material, fire door core is such as EPS (foam polystyrene), XPS (extrusion foaming polystyrene), foam PVC, foam PE, foam PUR and sponge rubber as raw materials and other products. But because of flammability and combustion of organic materials to produce VOC, hinder the application of these materials, this also appeared over the pursuit of improve flame retardant properties of organic materials, and enhance the level of fire safety phenomenon, it not only greatly increased the cost of materials, at the same time as the non environmentally friendly flame retardant are on fire the process will increase the amount of smoke and smoke toxic materials, fire may bring greater harm, so the organic material as the core material of the fire door is not desirable.

- Q: What is mineral fiber cotton? Yes, it's insulation.

- Heat preservation, this word is used well!!Mineral fiber cotton is something similar to cotton!Cotton insulation effect must be good!!

- Q: 8cm what is the sound volume of the soundproof cotton?

- You said if you want to use 8cm cotton insulation wall system to suppress the noise effect, must be added on both sides of the insulation cotton high density (or surface density) of the building materials, such as gypsum board, glass magnesium board, calcium silicate board, fiber cement board and so on. If we want to ensure that the partition wall should not be too thick, and to ensure the sound transmission loss of more than 50dB, it is not up to use the common plate, must use the Chong Ning insulation board and other professional sound insulation board, can achieve the wall thickness in the case of 100~130mm Rw, the weighted sound insulation amount reached more than 50~54dB, and the highest standards of sound insulation value reached the national standard of civil building insulation standards.

- Q: What is the difference between high-density rock wool board and hard rock wool board?

- Mineral wool, rock (mineral), cotton and glass wool, sometimes referred to as mineral wool, all belong to inorganic materials.

- Q: What are the advantages of inorganic fiber spraying in construction engineering?

- The company has professional inorganic fiber spraying construction qualification, can undertake a variety of insulation works, the main products of the company are: a rigid polyurethane foam composite board, polyurethane hard foam coating, inorganic fiber coating, glass wool and rock wool board auxiliary materials. Professional undertake spraying level external wall thin plastering system thermal insulation project.

- Q: The classification of exterior wall insulation and its main categories

- The second category is the engineering construction industry standards, external wall insulation engineering technical regulations. JGJ144 which includes five kinds of insulation system: the first is the EPS board exterior wall insulation system; second is the powder particles insulation slurry EPS exterior insulation system; third is the cast-in-place concrete wall of EPS board external insulation system; the fourth is a net cast system; fifth is the mechanical fixation of EPS steel wire the grid board exterior insulation system. With the existing external insulation insulation supporting standards, product standards and related engineering construction industry standards. The main supporting product standards are polymer based wall insulation glass fiber mesh; wall energy conservation project construction quality acceptance specification, that is, we know GB50411. Because most of these standards from 2003 to 2007 completed, but because of external wall insulation technology is developing very fast in recent years, the standard of life is short, basically all the standard in the revision, according to the development of technology, there are many standards are approved by the Ministry of construction, is being developed, the revision of the standard is JG149, the JG149 is the revision of the manuscript before the preparatory work. JG158 has just started the startup meeting and is preparing for the update.

- Q: Does water paint spray fire in underground space?

- NeededWater based brand fire retardant paint thickness is determined by base material, such as wood, steel structure, etc.:1. ultra thin structure fire retardant coating (0-3mm)2. thin steel structure fire retardant coating (3-7mm), fire-resistant 2-5h3. thick steel structure fire retardant coating (7-45mm), applicable to high-rise civil buildings, columns, general industrial and civil construction, fire up to more than 3H4. mineral cotton fire retardant insulation coating

- Q: What are the requirements for floor and exterior wall waterproofing in building construction?

- The joining of different structural materials shall be made of salt resistant fiberglass mesh or hot galvanized galvanized wire mesh of not less than 150mm on each side for anti cracking strengthening treatment

- Q: Why should the insulation board be spliced when it is installed?

- The EPS plate shall be bonded in a vertical arrangement and the vertical seam shall be staggered along the line. Insulation board construction fault seam stitching truth with brick walls are brick seam is a reason for strong security.

- Q: What are the differences and prices between rock wool board and mineral wool board?

- The habit of speaking, usually will use slag as the main raw materials to produce products known as mineral wool, and the use of natural rocks such as basalt or diabase as the main raw material for the production of a product called rock wool;

Send your message to us

Rock Wool Insulation Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords