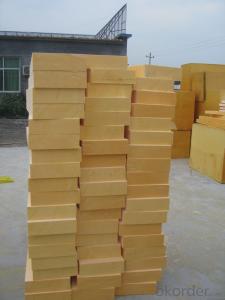

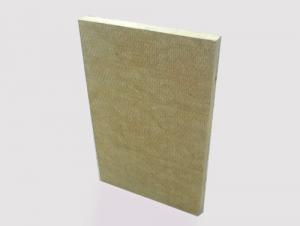

Rock Wool Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Cubic Meters m³

- Supply Capability:

- 200 Cubic Meters per Day m³/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

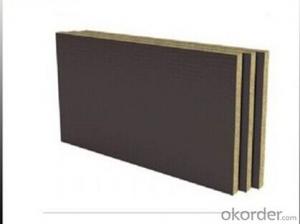

rock wool board1.Non-combustibility A1 GB Testing

2.Heat and sound Insulation

3.Prevent fire

4.Easy construction

- Q: What is the best sound proof cotton in the decorative plaster board partition wall? Mineral wool rock and glass wool.

- At present, the market is the best sound effect is said to be gradient sound-absorbing cotton, as well as high barrier sound felt. The price is relatively high, the price range is 55-80 yuan per square meter. The advantages of its products are more environmentally friendly, first of all, the construction will not cause skin itching. No emissions. It won't be pulverized. The sound absorption effect is reflected in the full frequency silencing, and has a good reduction effect on low frequency, intermediate frequency and high frequency sound. High barrier acoustic felt is reflected in its high damping performance. It can effectively restrain the sound propagation caused by resonance when it is attached to the thin plate. Usually relatively high-end, or official sites are more respected.

- Q: What are the exterior wall thermal insulation materials?

- Inorganic insulation material:A mineral mineral wool, perlite, vermiculite, diatomite, gypsum, slag, glass fiber, wool, aerated concrete, foam concrete, pumice concrete and its products, chemical synthesis of polyester and synthetic rubber with polystyrene, PVC, polyurethane, polyethylene, urea formaldehyde plastics and foam rigid ester and its products etc..Advantages: this kind of material does not decay, high temperature resistance, partial moisture absorption, easy to burn, more expensive.

- Q: How can the exhaust pipe of a gas water heater be insulated by going through the glass?

- The current gas water heater exhaust pipe does not require special thermal insulation when it passes through the glass.

- Q: What's the difference between glass fiber and mineral wool?

- Referred to as mineral wool. With non flammable, no mildew, no borers and other properties. Made into felt, blankets, mats, ropes, plates and so on. Used as sound absorption, shock absorption and heat insulation material.

- Q: What are the differences between slag wool and rock wool?

- Rock wool and slag wool, chemical composition and acidity coefficient comparison in our country, the main raw material for blast furnace slag slag cotton general or other metallurgical slag, the main raw material for rock wool basalt or diabase, the chemical composition of the differences between them are larger (

- Q: The difference between rock wool and mineral wool

- Originated in Hawaii. Rock wool products are high-quality basalt, dolomite as the main raw material, the high temperature above 1450 DEG after melting by four axis high speed centrifugal centrifuge international advanced fiber, and spray with a certain amount of binder, dustproof oil, water repellent cotton collector after collection, through the pendulum method, and three-dimensional method after cotton spreading curing, cutting, rock wool products form different specifications and applications.

- Q: What are common house thermal insulation materials?

- Can be divided into fibrous, porous, microporous, bubble, granular, layered and many other, here are some of the more common materials are briefly introduced.

- Q: How about the appearance of glass wool, mineral wool and asbestos?

- Glass wool belongs to a kind of glass fiber, it is a kind of man-made inorganic fiber. Quartz, sand, limestone, dolomite and other natural ore as the main raw materials, with a number of soda ash, borax and other chemical raw materials into glass. In the melting state, by means of external force, the system is thrown into flocculent fibers, and the fibers and fibers are made of solid intersection. They are intertwined with each other and show a lot of small gaps. This gap can be considered as a pore. Therefore, the glass wool can be regarded as a porous material and has good thermal insulation and sound absorption performance.

- Q: What material is fast heated and kept warm?

- The gap between the heating tube and the aluminum tube is filled with a heat conductive insulating elastic rubber, so that the heat can be rapidly transferred to the aluminum tube.Conductive heat insulation elastic rubber adopts silicon rubber base material, boron nitride, alumina and other ceramic particles as filler, the heat conduction effect is very good. Under the same conditions, the thermal impedance is smaller than that of other thermal conductive materials. Having a soft, clean, no pollution, high insulation and radiation characteristics of glass fiber provides good mechanical properties to reinforcement, anti piercing, shear resistance, tear resistance, with conductive pressure-sensitive adhesive.

- Q: What are the types of insulation materials used in pipes and equipment?

- Mineral wool is the industrial waste slag as main raw materials by melting, cotton like insulation material made by injection method and centrifugal method: cotton is a natural rock as raw material is made of mineral wool. The commonly used rock such as Xuan Wuyan, diabase, amphibolite etc..Mineral wool characteristics: mineral cotton and products is a high-quality insulation materials, has more than 100 years of production and application history. The utility model has the advantages of light weight, heat preservation, heat insulation, sound absorption, good chemical stability, no burning and corrosion resistance, abundant raw material sources and low cost:Main use of mineral cotton: its products are mainly used in the walls of dry buildings, roof, ceiling and other insulation, insulation and sound absorption, but also made of waterproof felt and pipe sleeve.

We specialize in producing comprehensive chemical products and heat-preserving building materials. We are one of the leading key enterprises in researching, designing and producing refractory materials, thermal insulation materials and deadening.Our products are widely applied in thermoelectricity, construction, smelting, petroleum industry, shipping industry, space industry and refrigeration industry. Our company has passed the evaluation of ISO9001 certification. We have independent rights of import and export. Our products sell well in Europe, North America and the Middle East.

We welcome you to cooperate with us.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2005 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | 29.00% Domestic Market 9.00% Eastern Asia 8.00% Western Europe 7.00% Africa 6.00% South Asia 6.00% Eastern Europe 5.00% Southern Europe 5.00% Northern Europe 5.00% South America 5.00% North America 4.00% Central America 4.00% Mid East 4.00% Oceania 3.00% Southeast Asia |

| Company Certifications | CE Certificate;EC declaration;ISO Certificate;Fireproof Class A1; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | TIANJIN,QINGDAO |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English, Chinese, Russian |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | average |

Send your message to us

Rock Wool Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Cubic Meters m³

- Supply Capability:

- 200 Cubic Meters per Day m³/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords