Road Roller BuyP830 Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name:P830 Road Roller

Parameter:

| Model | Unit | P830 |

| Min. working weight | kg | 14500 |

| Max. working weight | kg | 30000 |

| Axle load,wheels | kg | 2900 |

| Static linear load | kg | 12600 |

| Theoretical gradeability | % | 20 |

| Min. turning external radius | mm | 9000 |

| Min. ground clearance | mm | 290 |

| Tyre overlap amount | mm | 50 |

| Front wheel swing range | mm | ±45 |

| Compaction width | mm | 2750 |

| Ground pressure | kPa | 260~450 |

| Wheel base | mm | 3840 |

| Travel speed | km/h | 0~8 |

| km/h | 0~16 | |

| Tyre specification | 11.00-20 | |

| Tyre tread | Smooth | |

| Tyre amount | Front 5 rear 6 | |

| Engine model | SC8D180F2B1 | |

| Rated speed | r/min | 2000 |

| Rated power | kw | 132 |

| Engine oil consumption | g/kW•h | 232 |

| Water tank capacity | L | 2900 |

| Hydraulic oil tank capacity | L | 100 |

| Fuel tank capacity | L | 180 |

Advantages:

state-owned company

fortune 500 company

AAcustom

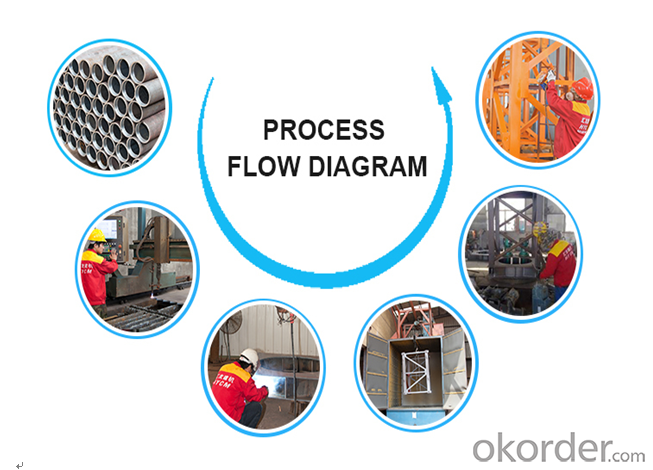

Why choose us?

1 sincre

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the equipment such as tower cranes, produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to solve all your tower crane installation and other questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s tower crane have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

- Q: Do you have a 15T roller?

- Yes, if you are interested, you can go to the building site of the construction machinery to look at it. There are many models and complete data..

- Q: The front wheel of a road roller is known to be cylindrical, with a width of 2.5 meters and a diameter of 1.2 meters. The front wheel rotates 8 minutes per minute. The 1. roller takes 20 minutes from one end of the road to the other. How many meters is the length of the road?. 2. what is the area of the road roller from one end to the other end of the road?. Process and description

- 1, turn 8 laps per minute, 20 minutes, a total of =20*8=160 circles;2, because the diameter is 1.2 meters, so a turn is equal to the front wheel perimeter =3.14*1.2=3.768 (meters);

- Q: The asphalt pavement here is divided into three layers, the two layer with rubber tire roller for rolling, the surface layer is needed for the rubber roller, wherein the two layer is below AC, the top layer is SMA series.

- So the asphalt pavement construction specification said.There is waterproof good, mainly depends on grading

- Q: In the process of asphalt pavement construction, can the wheel roller use diesel oil to clean the surface of the wheel?

- Generally, the use of steel roller, use plain water cooling and surface cleaning, the use of rubber tire roller, the use of diesel oil, it is only in the beginning or sticking wheel rolling, rolling wheel, after a while, the surface temperature, there is no need for.In the rolling, mainly by spraying some solvents make the wheels not sticky asphalt mixture, like diesel, oil film of asphalt mixture is damaged, and the cost is high, the construction unit and the use of rapeseed oil, water washing powder, the specification also mentioned some. In general construction, more diesel and water ratio of 1:1 solution is used.

- Q: Why use this roller when paving asphalt?

- Deliberately road repair uneven, driving when there is a sense of turbulence, or else easily sleepy

- Q: What are the foreign brands of domestic rollers? Which is the best?

- Has made the Luo Jian, Xugong, 31, etc., are imported with Napaike, Ingersoll Rand, BMW, Hummer and so on, which should be the best is not good, each one has his good points! I think Luoyang brand is good, a hundred years of history, the quality of hard, brand sound!

- Q: What is the exciting force of XCMG 23t vibratory roller?

- Are you sure it's Xugong 23T? I remember now is an even number, the singular tonnage built and Luo Lu Tong, other manufacturers are to symbolize the tonnage of 23 tons refers to the roller mechanical or hydraulic roller, (excitation force divided by 10) + its tonnage = tonnage for your vibration, XCMG 23 tons deep concern!

- Q: XCMG vibratory roller XP and XS? What do you mean?

- As the global economy is still in a slow recovery period, coupled with China's Roller Road enterprises export major market recovery is weak, in 2013, the road roller exports situation has improved, but the growth rate is weak. In 2013, the roller main production enterprises exported 3395 rollers, an increase of 1.8%. More than 200 enterprises export roller this year, Xugong, Xiagong, Liugong, Luoyang Road, Liuzhou, mountain and other 6 enterprises. This one, because of the influence of brand and overseas channels, up to 752 units of export Xugong roller, total sales of 18.5%; export 693 units Xiagong roller, has accounted for 42.6% of total sales; Liugong exports 556 units accounted for 39.85%.Beg for adoption

- Q: How can the asphalt be crushed between the road and the road, and the roller will cut the road along the stone

- Be close to the kerb and be careful about rolling, and shall not be too close to the edge.

- Q: Where are the rollers attached to the rollers?

- Upstairs said that the diesel engine oil, generally can find. Inside the reducer roller and the gear oil, is a heavy load gear oil, the Great Wall, Kunlun, Mobil, Shell and other series, such as the Shell VG150 heavy load gear oil, Mobil 629 series, the Shell VG150 gear oil is prescribed brand models of Sany products, and in the steel wheel and driving speed reducer vibration wheel, Shell VG140 gear oil filling in single drumroller rear axle reducer. Other brands of roller gear oils may have different brands and models. The steel wheel driving speed reducer addition: two is 90 degrees, and put the oil nut, screw it loose, start the engine running, one oil discharge outlet vertical reducer gear oil released after walking again, the two oil outlet of a vertical and a horizontal from the beginning, at the top of the filler filling gear oil, until the level direction of the oil port gear oil out of date. Refueling capacity of about 4.5L. Vibration wheel gear oil additive: three a 120 degree uniform oil adding and discharging port, oil discharge method ibid, to a vertical oil port down oil, after the oil discharge screw on a rotating steel wheel nut, make an oil outlet straight up, another loose oil the mouth slanting down (because the three port is 120 degrees.), from the mouth to the oil filling oil, until the oil port oblique gear oil out of date. Refueling capacity of about 11.5L. After oil addition: gear reducer bridge observation hole loosen nut central, loosen the direction by the reducer and put the oil nut oil (rear axle oil adding and discharging nut good judgment, nut at the top of a concave circular), and then go nuts loosen upper, middle gear oil to observe the outflow of oil can. Refueling capacity of about 18L. The above for Sany roller filling gear oil method and dosage, other brand roller may be different, but should be very similar, hope to help LZ.

Send your message to us

Road Roller BuyP830 Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords