P826 Road Roller BuyP820 Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name:P826 Road Roller

Parameter:

| Model | Unit | P826 |

| Min. working weight | kg | 14500 |

| Max. working weight | kg | 26000 |

| Axle load,wheels | kg | 3400 |

| Static linear load | kg | 8100 |

| Theoretical gradeability | % | 20 |

| Min. turning external radius | mm | 9000 |

| Min. ground clearance | mm | 290 |

| Tyre overlap amount | mm | 50 |

| Front wheel swing range | mm | ±45 |

| Compaction width | mm | 2750 |

| Ground pressure | kPa | 250~420 |

| Wheel base | mm | 3840 |

| Travel speed | km/h | 0~8 |

| km/h | 0~20 | |

| Tyre specification | 11.00-20 | |

| Tyre tread | Smooth | |

| Tyre amount | Front 5 rear 6 | |

| Engine model | SC8D156G2B1 | |

| Rated speed | r/min | 2000 |

| Rated power | kw | 115 |

| Engine oil consumption | g/kW•h | 224 |

| Water tank capacity | L | 3400 |

| Hydraulic oil tank capacity | L | 100 |

| Fuel tank capacity | L | 180 |

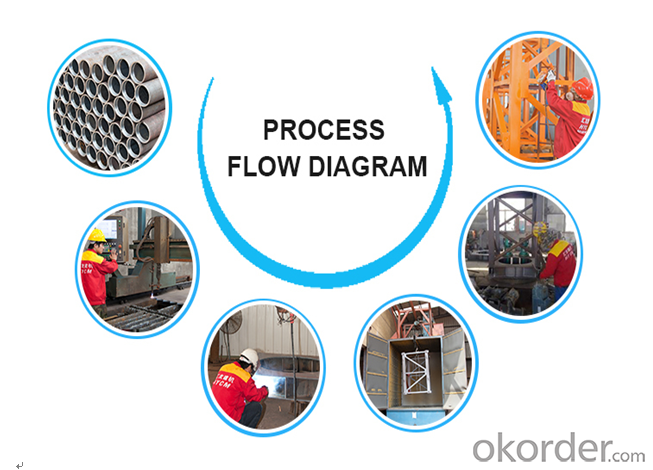

Advantages:

state-owned company

fortune 500 company

AAcustom

Why choose us?

1 sincre

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the equipment such as tower cranes, produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to solve all your tower crane installation and other questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s tower crane have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

Inquies FAQ

My dearest friend, if you want to buy our tower cranes, please tell us the following parameters. And we will make the most suitable project for!

1. Building height or tower crane working height.

2. Max load capacity and tip load capacity.

3. Span or jib length

4. Other Special requirements

- Q: Shaanxi impact roller manufacturers which scale is relatively large?

- To improve the entire strength and uniformity of subgrade treatment; impact rolling loess foundation or soft foundation collapsibility before filling, to meet the requirements of bearing capacity and stability of foundation; old road, gravel road, cement concrete pavement and the use of impact compaction technology renovation, can speed up the progress of construction, to project quality request and so on. At present, in addition to very few provinces, municipalities and autonomous regions, most of them have been widely used.

- Q: What is the advantage of vibratory vibratory roller in comparison with vibratory roller?

- Vibratory roller is more widely used than vibratory roller. As the bridge deck is not suitable for vibration compaction of asphalt compaction and repair, vibration and oscillation roller can be used oscillatory compaction.

- Q: Cement layer construction, do not roller compaction, OK?

- You asked the question very well! First of all, what you call the cement layer is the concrete structure of the road surface or the ground floor of the playground!

- Q: Excavators, forklifts, bulldozers, rollers with the same tonnage fight who badly rank

- Forklift tire chassis is running fast, but slow dig smart strong activity, only roller rolling speed is also slow, bulldozing clever activity than low thrust but also digging machine.

- Q: XCMG alarm lamp for vibratory roller

- As the global economy is still in a slow recovery period, coupled with China's Roller Road enterprises export major market recovery is weak, in 2013, the road roller exports situation has improved, but the growth rate is weak. In 2013, the roller main production enterprises exported 3395 rollers, an increase of 1.8%. More than 200 enterprises export roller this year, Xugong, Xiagong, Liugong, Luoyang Road, Liuzhou, mountain and other 6 enterprises. This one, because of the influence of brand and overseas channels, up to 752 units of export Xugong roller, total sales of 18.5%; export 693 units Xiagong roller, has accounted for 42.6% of total sales; Liugong exports 556 units accounted for 39.85%.

- Q: What's the difference between a three wheel roller and a two wheel roller?

- Three roller is the static compaction, without vibration function, used for compaction of embankment or base, two roller generally called double drum vibratory roller, roller tonnage than three small tonnage, mainly used for oil pressure, the asphalt concrete, with vibration function, the upper two wheels a water tank, can go on wheels to prevent water roller compacted asphalt concrete glued to the wheels.

- Q: Vibratory roller pressure and steel roller compacted what is different

- You should make the cement stabilized layer of double steel wheel vibratory roller, you should first use vibratory roller vibration compaction, and then do not open vibration to smooth surface. Just do not open the vibration pressure several times, the static pressure only to surface dense, but the bottom is still more loose

- Q: Will the Apocalypse Tank be pressurized back?

- Even if the tanks in the real world are out of the way, don't you think the tanks are just as powerful as the ones on TV? A real world of tanks can be penetrated several meters thick steel plate,

- Q: 31 How about roller?

- In fact, each enterprise has its product positioning, the use of the object has its choice models considering how to choose from that the highest cost-effective products, eyes of the beholder.

- Q: What is the difference between an impact roller and a vibratory roller?

- Vibratory roller is the role of the cement becomes more dense and smooth wheel roller is the role of improving smoothness of pavement, so smooth wheel roller replace vibroll.

Send your message to us

P826 Road Roller BuyP820 Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords