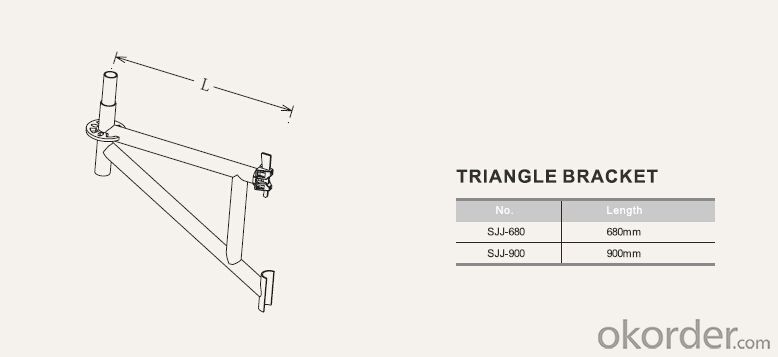

Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm

Material :Q235 carbon steel

Surface treatment :Hot dip galvanized

Length :600MM/900MM

Thickness :2.4MM/2.5MM/2.75MM/3.0MM/3.25MM

Descriptions of Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm

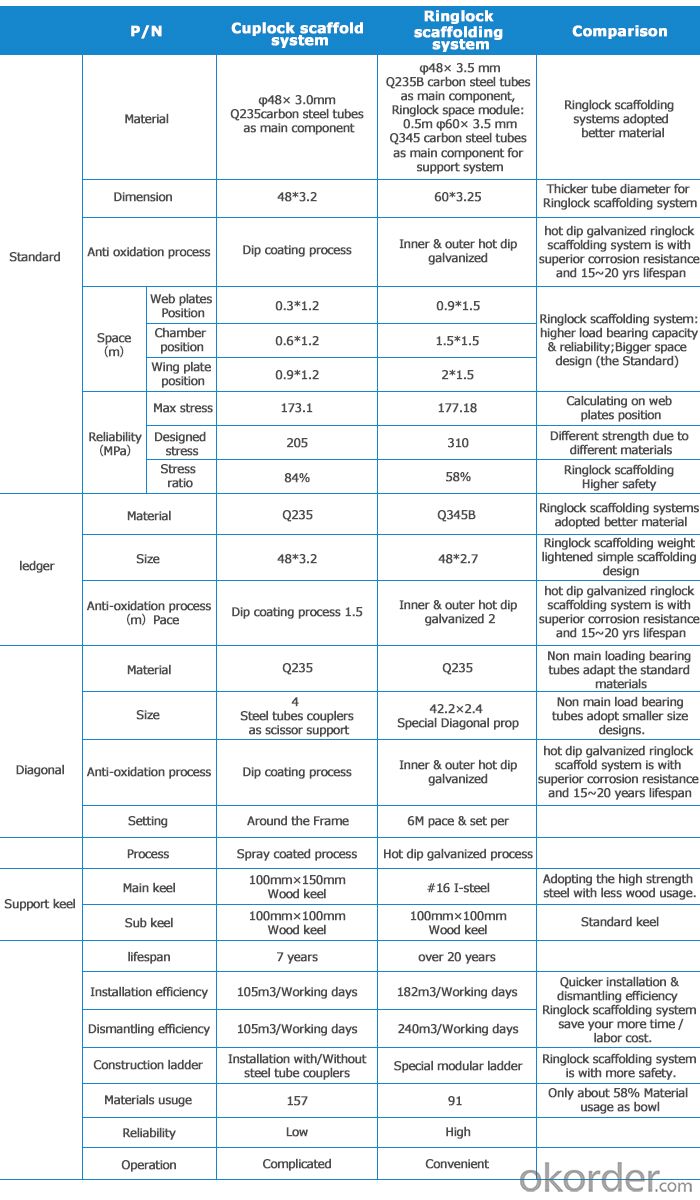

The ringlock Scaffolding and ringlock support system are popularly used in building construction, outside form, cast - in - situ beam, formworks support, canopy frame, bridge & tunnel, stage construction applications and welcomed by building construction companies, construction & decoration companies, leasing companies, media & advertising companies and other users。

Our patented Ringlock Scaffolding and Ringlock support system with surface galvanizing process provided the buyers with higher safety & benefits. Annual output: 7000 tons.

The strong ringlock scaffold system is with 2~3 times installation & dismantling efficiency higher than the cuplock scaffolding system, but only with half steel usage and 75% investment cost.

Our low cost & high benefits Ringlock Scaffolding System with hot dip galvanized surface treatment are easy to installation & disassembly.

Our Ringlock Scaffolding and Ringlock support system with 200 KN high loading bearing capacity are buyers’ safe & professional choice.

Patented R&D and production single personal installation with a hammer only. Greatly saved the steel usages compared to steel tube with couplers.

Details of Tri-angle Brackets

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: They can see a good place to anchor it but they won't start to build the scaffolding. I've used different builders and tried different bits of the paths, but its just not working. What do I do?

- Hey love, I'll try to help but right now I'm pretty exhausted so it won't be my best. I am going to link a website that has tips and tricks, and hopefully you'll see something that fits. I hate when I get provided a link that doesn't though, so I also suggest posting to the forum on the website. Strategy guide may be a good place to start. They are all die hard fans, and always happy to help. I assure you your question will be answered very quickly once you sign up. I wish I could help more, but I was more of a VV2 player. If you don't get the help you need from the forum, edit and I will look when I am able to think. ;) Also, do you think it may be a glitch or just something your missing? If you emailed lastdayofwork, they might be able to suggest a patch if that's the issue. Good luck! :)

- Q: Cantilever scaffold technical disclosure

- First, the foot of the structure of the quality standards:1, steel pipe:(1) the steel pipe shall have the product quality certificate and inspection report with the outer diameter of 48mm and the thickness of 3.5mm of the steel pipe welded to the steel pipe of 3. Rust must be replaced, not to be used to build the frame.

- Q: I plan on playing tennis and doing track and field at school... Im getting the piercing this month and it won't be healed in time to take it out. How can I conceal it or possibly even help it heal faster??

- Why no longer enable your ear pieced lower back while you're off out of your prepare like in case you have a much better than one week holiday so which you do no longer could desire to get rid of and placed your jewelry many of the time. a minimum of you could evade preserving your ears many of the time and evade the an infection. you could enable your ears heal ideal. in case you could no longer wait to have your ear pierce lower back once you get rid of and placed decrease back your jewelry make it beneficial you sanitized your palms by skill of washing and employing alcohol. placed Neosporin (antibiotic ointment) on your new pierced jewelry and on the jewelry itself in the previous putting it decrease back. in the previous additionally they use medicated string or thread on the ears for the piercing of latest child toddlers.

- Q: For the current stage of China's construction should not strengthen the specific meaning of scaffolding and support by way of the scaffolding and support the specific distinction and significance

- In order not to be involved in the whole system due to local errors, the scaffold must be separated from the formwork support, forming a stable system.

- Q: The outer hanging scaffold board 12 embedded parts embedded in the crack?

- Is the pre embedded parts installation (burial) component hidden in the works inside. Is placed in the structure of casting fittings, for masonry superstructure when the lap. In order to facilitate the installation of engineering equipment based on external fixation. Most embedded parts made of metal, such as steel or iron, can also be used in wood, plastic and other nonmetallic rigid materials.

- Q: What does my earth science teacher mean when he says to do a powerpoint with Link Scaffolding,how d u do it?

- Link Scaffolding = A search found no answer. - Ask teacher to clarify.

- Q: How to maintain the scaffold after use

- Tool type scaffolding (such as door frame, bridge frame, hanging basket, receiving table) in the removal of the need to stop the maintenance and timely maintenance, and supporting storage.

- Q: Is it easier to build a disc scaffolding system than a bowl buckle scaffold?

- Disc scaffolding systemIs a new type of scaffolding, the product was introduced in Europe in the last century in 80s, is the upgrading of products after the bowl buckle scaffold. Also called chrysanthemum disc scaffolding, scaffold system, disc scaffolding system, buckle disc scaffolding, layher frame (layer frame, Lei Ya frame, because the basic principle of the scaffold is by the German LAYHER (Lei Ya)'s invention, the industry has been called the "thunder sub frame"

- Q: I really want a scaffold piercing and I can pay for it, I get good grades, I do all the chores I have to do, I spoke to them calmly and everything. Yet they still won't let me. My dad said that I will be grounded forever and everything but last time I got grounded, I went to a party the next day so what should I do?

- dont do it. when your parents say grounded, you may be let off easy but if is about your body then if you get it your in deep ****. also your parents could see this question and then you would be in even more trouble. please dont get it. also things like that are really hard to hide from parents. if your 18 years or older llegally they cant stop you from doing it. i dont think you should do it.

- Q: male scaffolders only if i was swinging on the scaffold would ya stomp on my fingers with ya workboots on?

- Had a hooker climb up the ladder to the 3ed floor one time....didn't stay long though!

Send your message to us

Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords