Ringlock Standard Easy Assembly Top Quality Metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

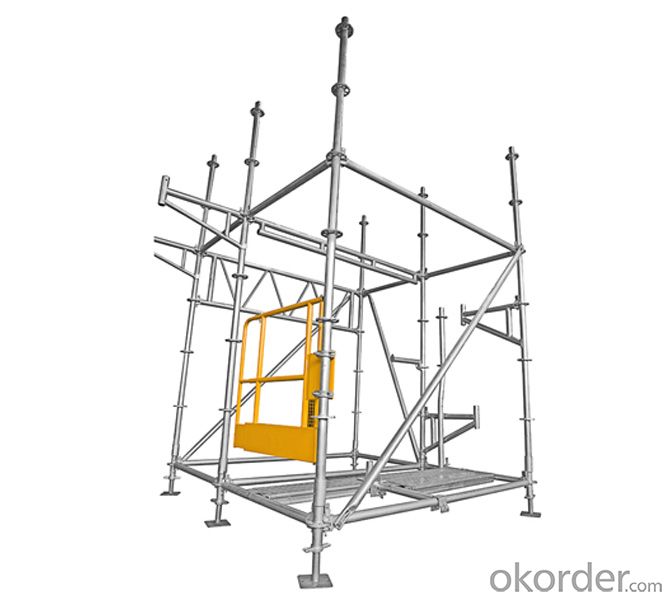

Ringlock Scaffolding

Ringlock is a modular scaffold system which can provide major savings in labor costs while meeting the demands for safety, ease of handling and reductions in maintenance.

Ringlock scaffold has the following features:

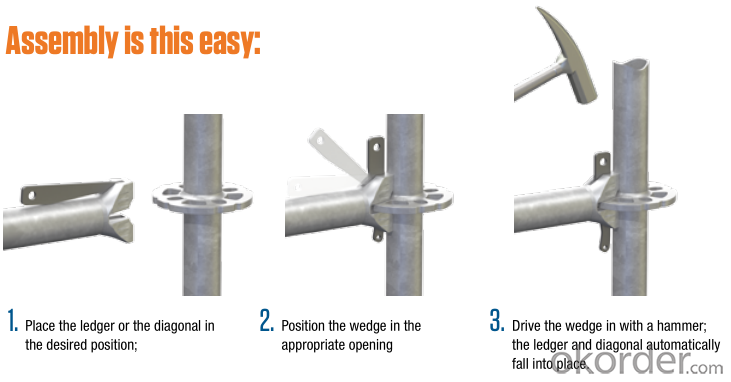

1.Quick erection: Ringlock scaffold are all pre-measured and just a hammer is required when erection.

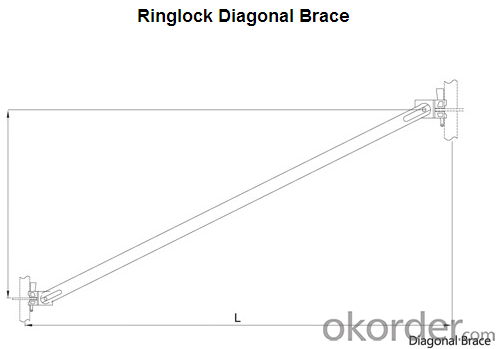

2.Safety: The reliable wedge connections prevent ledgers and diagonal braces from any kind of loosening, The rigid, right fit of all connections with concentric derivation of loads guarantees safety even at great heights.

Main Features of the Ringlock Scaffolding

Place of Origin | Beijing, China (Mainland) |

Product Name: | Ringlock Scaffolding |

Custom Code | 7308400000 |

Color | Silver, golden |

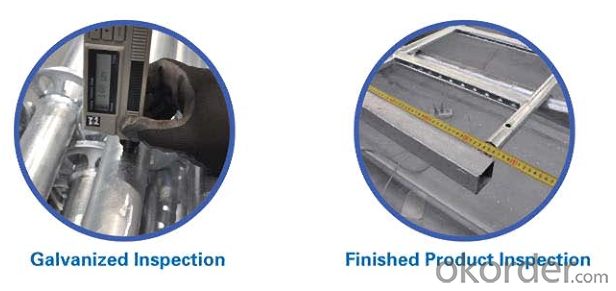

Surface treatment | Painted,Hot-Dip,Galvanized,Electro Galvanized, Powder Coating |

Material | Q235,Q345.etc |

Package | Customized Package |

Payment Terms | T/T,L/C |

Delivery Detail | 15-25 Days |

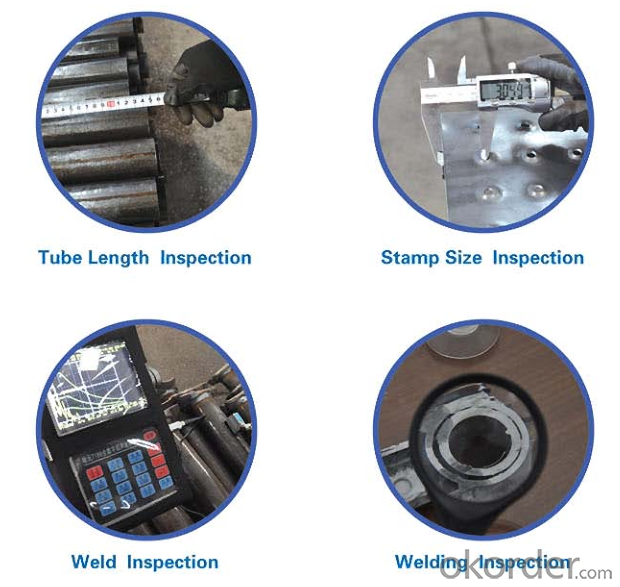

Quality Control | IS09001 Certification, Quality Test |

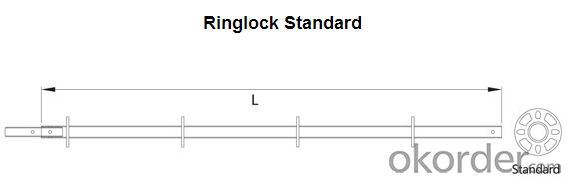

Standard | 48.3*3.25*4000mm |

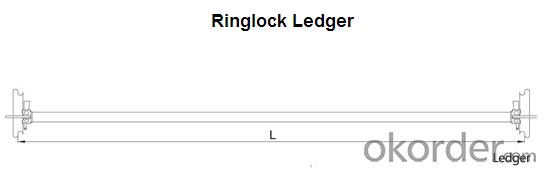

Ledger | 48.3*3.25*3072mm |

Ledger End | 1.2kg |

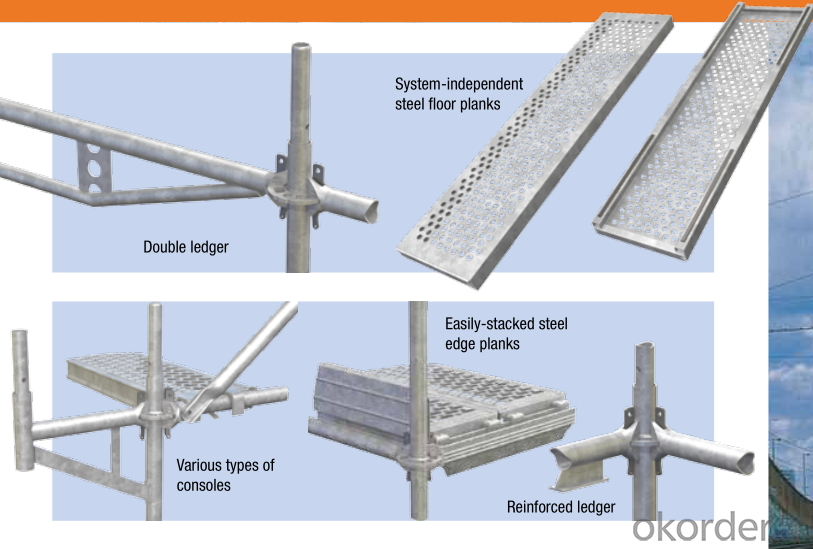

Advantages

1)To be erected easily and quickly

2)Installed to different angels with rosettes of

two different hole being positioned there

3)Ringlock scaffolding provides complete flexibility to lock in any angel.

4)Diagonal braces are to be tailored in

accordance with the lengths of vertical and horizontal tubes

Specification of Ringlock Scaffolding

The Standards(Verticals) | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

3000 | 3/3.25 | 48 | HDG/Painted | |

2500 | 3/3.25 | 48 | HDG/Painted | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1500 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

500 | 3/3.25 | 48 | HDG/Painted | |

The Ledgers(Horizontals) | ||||

Effective Length(mm) | Tube Thickness(mm) | Tube Diameter | Surface Treatment | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1770 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

The Diagonal Brace | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

2411 | 3 | 48 | HDG/Painted | |

2244 | 3 | 48 | HDG/Painted | |

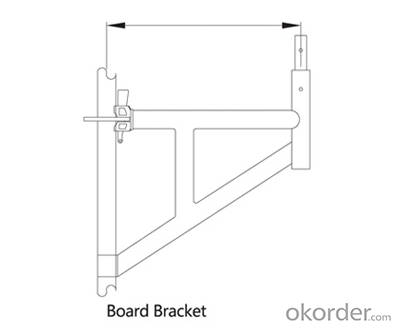

The bracket | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

730 | 3 | 48 | HDG/Painted | |

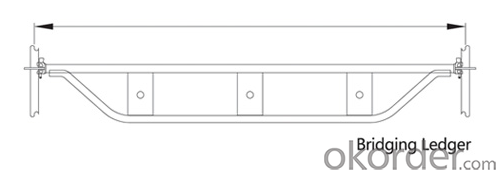

Plank | ||||

Effective Length(mm) | Width(mm) | Height(mm) | Surface Treatme | |

2050 | 480 | 45 | HDG | |

1820 | 480 | 45 | HDG | |

3000 | 240 | 45 | HDG | |

2000 | 240 | 45 | HDG | |

1000 | 240 | 45 | HDG | |

Hollow Head Jack And Jack Base | ||||

Length(mm) | Tube Diameter(mm) | Size of Plate(mm) | Surface Treatment | |

600 | 38 | 150*120*50*4 | HDG | |

600 | 38 | 150*150*4 | HDG | |

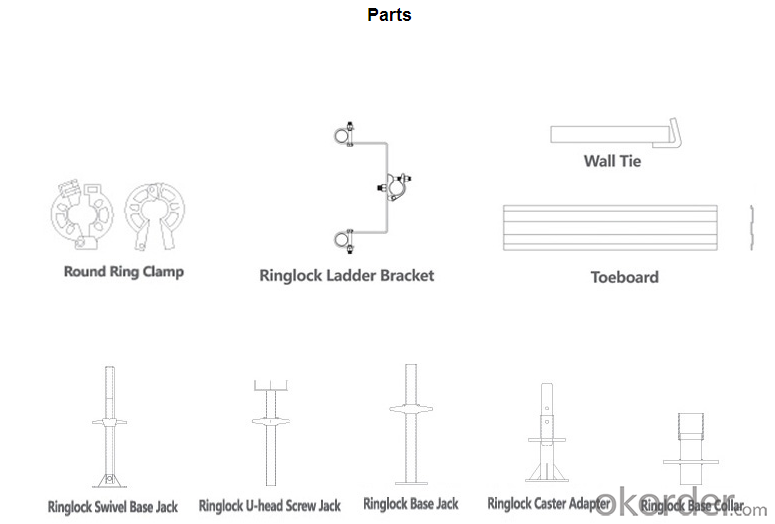

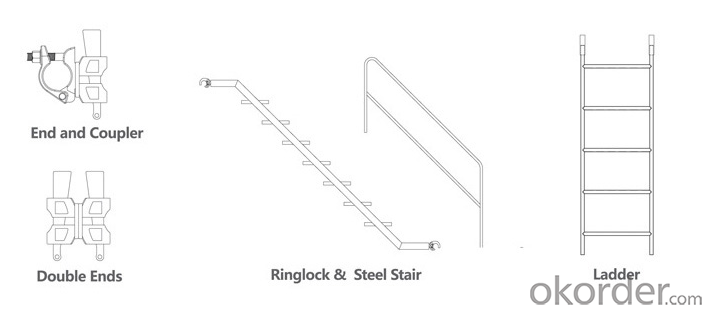

Accessories

Packing

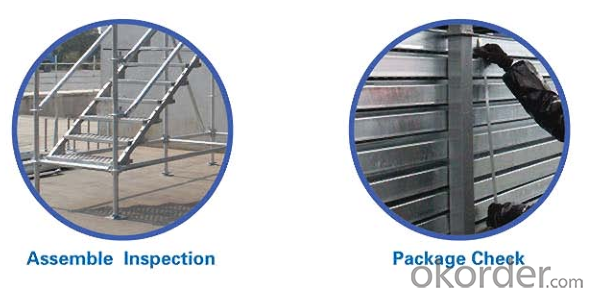

Inspection

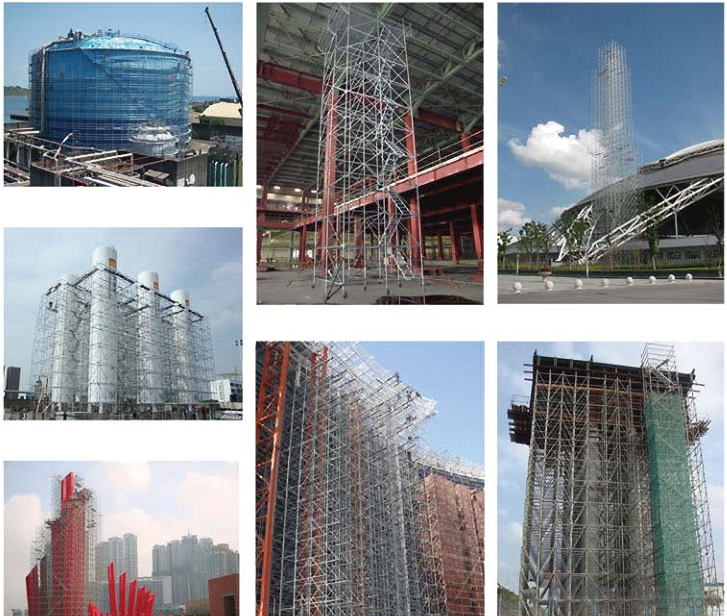

Project

More Photos

- Q: In the process of high-rise building construction, bowl buckle type steel pipe scaffolding foundation and foundation treatment should meet the requirements

- Landing bowl-scaffold when erecting height H is less than or equal to 20m according to the ordinary routine shelf erection, erection of a height when H > 20m and ultra high, heavy and large span of the template support system must make special construction design and structural analysis and calculation.

- Q: What is the significance of the three scaffold scenes in the Scarlet Letter?

- Scaffold Scarlet Letter

- Q: I got mine done a few days ago and it's super swollen and bruised. I've been told they have pierced it wrong as they didn't use any needles and they just shoved the bar straight through. Is that right? Or should they have used needles? Thank you!

- They definitely should have used a needle!

- Q: its a current ad on uk tv, has a really nice song and there is a couple sitting on top of the stage scaffolding and they share a treat , like a chocolate pudding or ice cream. I really want to know the song, but at the moment i cant even remember what the product is, which is exasperating as i can't research further....

- not sure of the song but i know the advert is for hagen das ice cream so you should be able to look it up on youtube!x

- Q: this work wont start till tuesday and the scaffold has blocked my sky tv. am i within my rights to remove this scaffolding?

- How about giving your TV a break and enjoying the weather. The scaffold will only be temporary.

- Q: Pankou scaffolding and fastener type steel tube scaffold which is better?

- Pankou scaffolding is attracting more and more attention. The construction field has formed a round bowl buckle as the main body, steel fasteners for auxiliary "situation.

- Q: this is the excerpt-We have witnessed a people [Muslims] to each and every one of whom death is preferable to life, and humility to prominence, and to none of whom this world has the least attraction. Their leader is like one of them: the low cannot be distinguished from the high, nor the master from the slave. And when the prayer time comes, all wash their hands and feet and humbly pray.QUESTION: How does this writer describe the Muslim people?Sorry i know this is my homework i just need help analyzing it. Is the writer describing them as unliked people? or people he respects?

- people he unlikes and can u help me make an abc book about the revolutionary war

- Q: Pankou scaffolding is good for

- Scaffolding, low cost, high efficiency, convenient disassembly build effort, on the ground after the installation of integral hoisting.Pankou scaffolding pole high load intensity, M60 series of bearing capacity can reach 19-21 tons.

- Q: I Got my scaffolding piercied 3 weeks ago i think or 2 , and school starts soon and im doing gcse pe :| loool i need to know how i can hide it ? and if i can just put tape over the balls will they care about the bar in the middle? please help me haha would it be easier to just wear clear balls ? because then im not actually taking the piercing out so it wont get infected or anything?

- you can get two separate retainers to put in each hole.. retainers are clear jewelry, that you use to hide piercings.

- Q: How to allow the height of the bowl - shaped steel tube scaffold

- The risk of a larger segment of the project safety management approach, the fifth set up a height of more than 50m of the floor type steel scaffolding, construction units must organize experts to demonstrate the program.Standard Specification for Standard Specification for bowl buckle steel tubular scaffolding

Send your message to us

Ringlock Standard Easy Assembly Top Quality Metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords