Ring Lock High Quality and Competitive Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

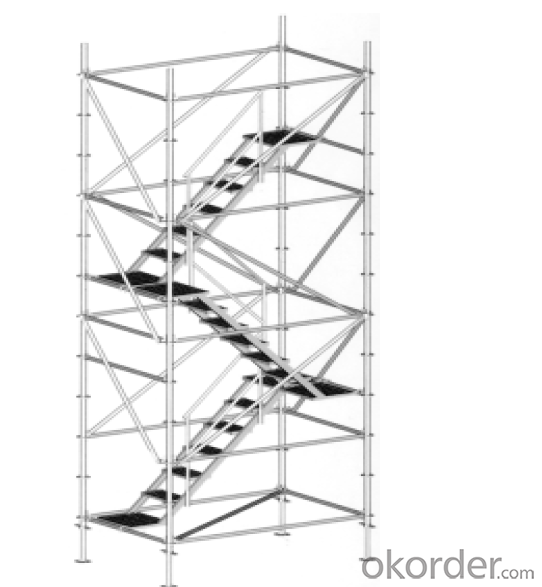

1. Structure of Ring-lock Scaffolding

Ring-lock Scaffolding consists of cup-lock connector, post, cross bar, diagonal brace, base and top brace. Safe and convenient to operation, fast to assemble and dismantle, widely used in scaffolding construction, such as formwork scaffold and fitment construction.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Ring-lock Scaffolding

.Each Ring-lock is welded on post every 0.6m. Choose step pitch based on mechanical requirements

.When installing the scaffolding, insert ledger connector into the pole of the cup-lock, then hammer ledger connector to finish fastening

.The more load, the more reliable fasten

.Ring-lock Scaffolding has no special retaining member and no active parts. It’s easy and convenient to operation with integral low costs

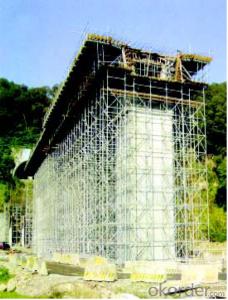

3. Ring-lock Scaffolding Images

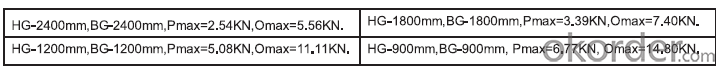

4. Ring-lock Scaffolding Specification

.Buckling resistance: 2KN.M when concentrate load on cantilever and 6-9KN.m when evenly distributed load

.Design load of cross bar

.Design Lord of base:Pmax=60KN

5. FAQ of Ring-lock Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Ring-lock Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Ring-lock Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What is the bowl buckle scaffold operating layer

- Mainly play a supporting role. The second is the external wall, structural decoration and other construction use of steel scaffolding

- Q: I have been siding my house using pump jack scaffolding on wood poles. I am at a second floor section that is located over a pitch roof. Is there a safe way to mount poles on top of pitch roof to finish this section?

- At that height you need support beams, scaffolding alone won't cover it.

- Q: How to calculate the cost of scaffolding erection

- The general case is to artificial fee fee based fees, high-rise building scaffolding demolition charges, high fees are in fixed price as the base fee of labor costs, but the valuation when high costs denominated base also includes the high-rise building costs, labor costs and fee scaffolding. In addition, the rates are different, you should refer to the various regions of the fixed fee rate, hoping to help you!

- Q: I have already got a cartilage piercing, and I was considering getting a scaffold bar. I don't mind pain, but soon as it was in an unusual place, I was just a little bit curious.

- It's pretty much the same thing. People like to say its really painful, but really its just getting two cartilage piercings in a row. The sting only lasts a second, its not bad at all. you may have a headache afterwards, but thats the worst of it. mainly people say its really bad because its likely they went to a crappy piercing place and didnt really care who pierced them. if you do research and get someone with lots of experience, you should be fine. like my piercer has been doing them for about 15 yrs and does thousands a year. inexperienced ones are the worst. also whats helpful is if you ask the piercer to do one piercing at a time with separate needles, cause some like to do both with the same needle, piercing the second one without pulling the needle out of the first one, which would make it very uncomfortable.

- Q: Why is there so much unnecessary scaffolding in NYC?

- Must belong to someone's cousin. Buildings need cleaning too.

- Q: In the settlement, there are also iron welded steel pipe welded pipe unit price information price, should I be in the settlement in which unit pricing is reasonable? What is the difference between these two materials? Can provide a better basis for authority. Thank you

- Versatility: the main components are the use of ordinary fastener type steel pipe scaffolding, steel pipe can be used to connect fasteners, versatility.4) the bearing capacity is large: the vertical rod connection is a coaxial core socket, and the cross bar is connected with the vertical rod by a bowl buckle joint. And the axial line of each member is placed at one point, and the node is in the plane of the frame. (the entire frame bearing capacity, about the same clear fastener type steel tube scaffold condition is improved by more than 15%,)

- Q: I NEED THE THREE SIGNIFICANCE OF THE SCAFFOLD IN THE SCARLETT LETTER CAN ANY ONE HELP ME!!!

- just okorder i had to read that book, i hated it.

- Q: What do you suppose is Hawthorne's purpose for the scaffold? IN other words, what is the role or function of the scaffold scenes in this novel? Are any important philosophical truths revealed?

- The scaffold is the only place where Hester, Dimmesdale and Pearl are together in the town. The first is when Hester is being interrogated by Dimmesdale, the second is at night when they meet him, and the third is at the end of the book. The Scaffold is used by Hawthorne just like it would be in real life, to bring a crime to the public, just as it does in the book. Not sure about philosophical truths, nothing like that I could think of at the moment.

- Q: How to allow the height of the bowl - shaped steel tube scaffold

- Bowl buckle scaffoldBowl buckle scaffold is a new type of steel scaffolding. The original scaffold with tooth bowl joints, with spelling and rapid, saving, stable and reliable structure, fully equipped, strong versatility, large bearing capacity, safe and reliable, easy processing, easy loss, easy to manage, easy transportation, wide application etc.. Has received several awards at home and abroad, is one of the ten key technologies to promote the Ministry of construction in 2000.

- Q: Whats a scaffold piercing?

- upper ear...duhhhh

Send your message to us

Ring Lock High Quality and Competitive Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords