Reinforcement Geogrids for Fiberglass Road Pavement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid for Road Pavement Reinforcement

Description Of Fiberglass Geogrid for Road Pavement Reinforcement:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Main Features of Fiberglass Geogrid for Road Pavement Reinforcement:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid for Road Pavement Reinforcement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4 | <4 | <4 | <4 | <4 | <4 | <4 | <4 | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid for Road Pavement Reinforcement:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

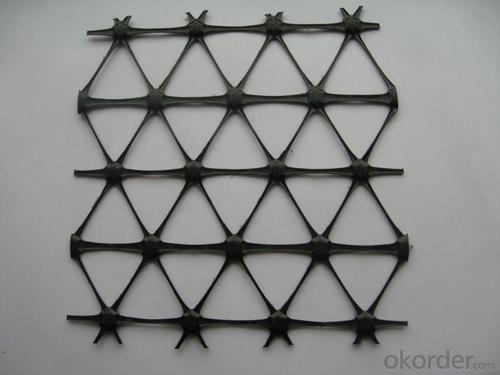

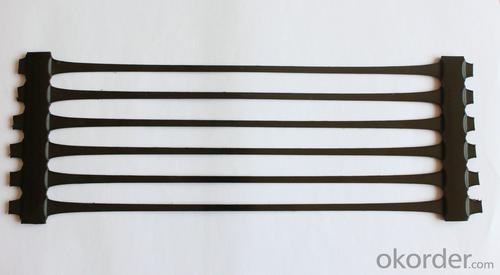

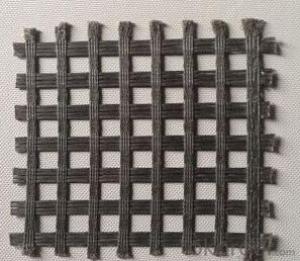

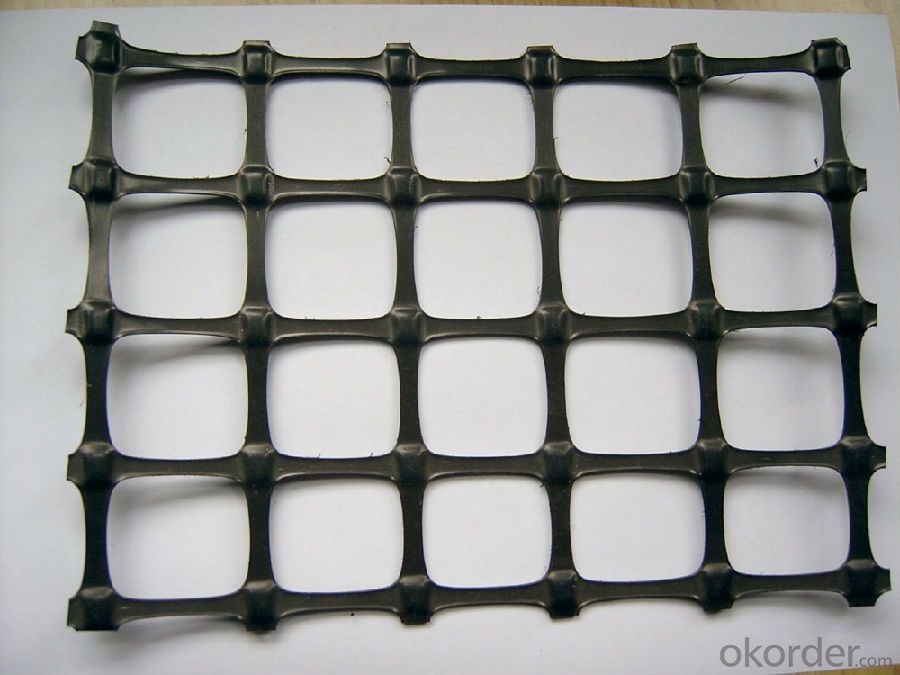

IMages of Fiberglass Geogrid for Road Pavement Reinforcement:

FAQ of Fiberglass Geogrid for Road Pavement Reinforcement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are flexible and durable materials that can reinforce soil and improve its stability. In seismic zones, where the ground is prone to shaking and instability during earthquakes, geogrids can effectively enhance soil resistance to lateral movement, reduce soil liquefaction, and provide greater overall stability to structures. Their ability to distribute loads and increase soil confinement makes them highly suitable for use in seismic zones.

- Q: How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first clearing and preparing the site, followed by laying a layer of geotextile fabric over the prepared area. The geogrid is then unrolled and placed on top of the fabric, ensuring proper alignment and overlap. The edges of the geogrid are secured using pins or stakes. Finally, the geogrid is covered with additional layers of soil, aggregate, or asphalt, depending on the specific project requirements.

- Q: What is the cost per cubic meter of reinforced earth retaining wall

- Geogrid plays a very important role in road construction, which is mainly to reinforce roadbed and delay aging. The following is a detailed introduction: Geogrid on the road is mainly used for soft foundation treatment, roadbed reinforcement, slope protection, abutment reinforcement, wing wall, retaining wall, isolation and reinforcement of soil engineering

- Q: Product features: high strength, small deformation; creep; corrosion resistance, long service life: steel plastic geogrid with plastic material as a protective layer, which is supplemented with a variety of additives in aging resistance, oxidation resistance, corrosion resistance to acid and alkali, salt and other harsh environment

- Normal should read Zha, but because of the dialect or engineering terminology habits, read Shan, habit, this is just a personal idea.

- Q: Can geogrids be used in underground tunnels?

- Yes, geogrids can be used in underground tunnels. Geogrids are commonly used in tunnel construction to reinforce the surrounding soil or rock, providing additional stability and reducing the risk of ground movement. They help distribute the loads and prevent soil or rock collapse, ensuring the safety and longevity of the tunnel structure.

- Q: Can geogrids be used in retaining wall drainage systems?

- Yes, geogrids can be used in retaining wall drainage systems. Geogrids are commonly used to reinforce soil and provide stability to retaining walls. They can also be employed as part of a drainage system to help manage water pressure and prevent the accumulation of excess water behind the wall. By allowing for efficient drainage, geogrids can enhance the overall performance and longevity of retaining walls.

- Q: Can geogrids be used in reinforcement of rail embankments and cuttings?

- Yes, geogrids can be used in the reinforcement of rail embankments and cuttings. Geogrids are commonly utilized in civil engineering projects to improve the stability and strength of soil structures. By incorporating geogrids into rail embankments and cuttings, the soil is effectively reinforced, preventing erosion, reducing settlement, and enhancing overall stability. This reinforcement technique helps to ensure the longevity and safety of rail infrastructure.

- Q: Can geogrids be installed on steep slopes?

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in slope stabilization and reinforcement projects, including on steep slopes. They help enhance soil stability and prevent erosion, making them suitable for installation on steeper slopes where erosion and soil instability may be more prominent.

- Q: Can geogrids be used in landfill liners?

- Yes, geogrids can be used in landfill liners. They are often used as part of a composite liner system to enhance the stability and performance of landfill liners. Geogrids provide reinforcement and improve the tensile strength of the liner, helping to prevent soil erosion and enhance the overall integrity of the landfill liner system.

- Q: Glass fiber mesh cloth is mainly used in what place

- Main applications are widely used in

Send your message to us

Reinforcement Geogrids for Fiberglass Road Pavement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords