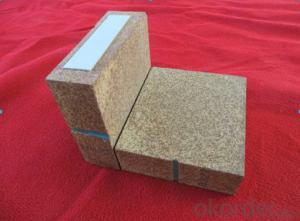

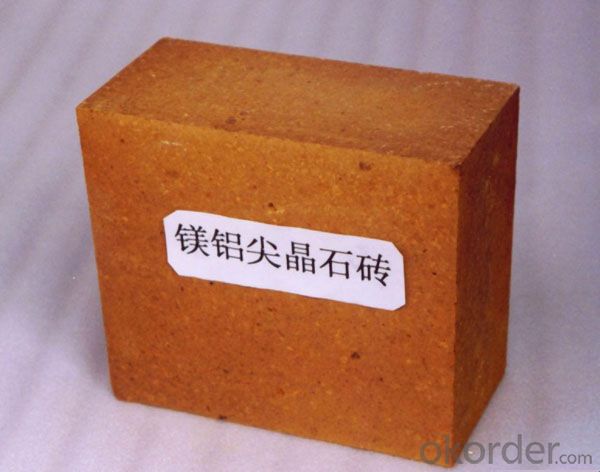

Corundum Brick for Refractory Magnesium Aluminate Spinel Bricks in Large and Medium Sized Lime Kilns

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | in plastic sheet and then in wooden pallets. |

| Delivery Detail: | about 30 days |

Specifications

1. High temperature

2. A variety of grade

3. With competitive prices

4. Various models and size

Product Description

DESCRIPTION:

Magnesium aluminate spinel brick is a new product developed by our company according to the development current situation of building material industry and the performance characteristics of all kinds of lime kilns.

The product has the advantages of good alkali-resistance, good erosion resistance, good thermal stability, high crushing strength, and high refractoriness under load.

ADVANTAGE:

advantages of good alkali-resistance, good erosion resistance, good thermal stability, high crushing strength, and high refractoriness under load.

APPLICATIONS:

All kinds of large and medium sized lime kilns, such as rotary kiln, sleeve kiln, and shaft kiln.

| ITEM | INDEX |

| MgO % | ≥82 |

| Al2O3 % | 13-15 |

| Fe2O3 % | ≤0.8 |

| Bulk Density g/cm3 | ≥2.98 |

| Apparent Porosity % | ≤17 |

| Cold Crushing Strength(Mpa) | ≥60 |

| Refractoriness Under Load | ≥1700 |

| Thermal Shock Resistance | ≥15 |

| Refractoriness | ≥1800 |

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- In addition to AZS33# and AZS same co crystallization in vitro, 36#AZS due to the increase of chain like zirconia brick more crystals, while the glass phase content is low, so 36# AZS corrosion resistance has been further enhanced, so is suitable for the rapid flow of molten glass or high temperature region.AZS36 s is an excellent product in the AZS series. It has high resistance to glass liquid erosion and low pollution. It is usually used in the key parts of the glass furnace, such as the pool wall near the hot spot.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What are the advantages of refractories?

- Basic refractory material generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials. This kind of refractory material has higher refractoriness and strong resistance to alkaline slag.

- Q: Wave tile and throwing glaze, tile which good?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: What is the hardness of corundum refractory bricks?

- Al2O3 containing more than 90% greater than the refractory brick called corundum refractory brick, also known as pure alumina refractory products. Corundum has a high hardness (9 Mohs hardness) and a high melting point. These are closely related to the firmness of the Al - 0 bond in the structure. Therefore, a-Al2O3 is the main phase of making high temperature refractory bricks and high temperature electrical insulating materials.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: What is the difference between corundum and high alumina?

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

Send your message to us

Corundum Brick for Refractory Magnesium Aluminate Spinel Bricks in Large and Medium Sized Lime Kilns

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords