Corundum Brick - Corundum Ladrillos

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

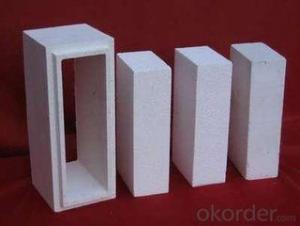

Alumina content more than 90%, is given priority to with corundum crystal phase of refractory products.

High room temperature compressive strength (up to 340 mpa).High rul start temperature (greater than 1700 ℃).

Good chemical stability, acid or alkaline slag, metal and glass, etc. Have strong ability of resist.Thermal shock stability is related

to its organizational structure, the erosion resistance of dense products is good, but poor thermal shock resistance.

Divided into sintered corundum brick and fused corundum brick two kinds.Respectively using sintering alumina and fused

corundum as raw materials or Al2O3 / SiO2 than high bauxite clinker and sintered alumina, made by sintering process.

Also can use phosphoric acid or other adhesives made don't burn corundum brick.It is mainly used for blast furnace and

blast furnace hot blast stove, furnace refining furnace, sliding water apparatus, glass furnace, and petrochemical industrial furnaces, etc.

- Q: Application of electric high temperature regulating valve?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q: What is the main component of corundum?

- Corundum is mainly used in advanced grinding materials, watches and precision mechanical bearing materials. A ruby based artificial crystal used as a laser emitting material. Ruby and sapphire are corundum minerals. Except for the starlight effect, only translucent transparent and vivid corundum can be used as gems. The red is called ruby, while the other tones of corundum are commercially referred to as sapphires.

- Q: What material is used in an iron smelting furnace?

- Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on.

- Q: What is the price of concrete self insulation bricks?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: What's the jade stove for?

- Corundum furnace for corundum smelting furnace, usually electric arc furnace for smelting dense corundum, corundum, white corundum, zirconia corundum, magnesia, magnesium aluminum spinel and fused refractory materials, professional design, Xi'an Xinda furnace engineering limited liability company manufacturing corundum furnace.

- Q: High temperature refractory material?

- Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q: What are the refractory materials?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

Send your message to us

Corundum Brick - Corundum Ladrillos

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords