Refractory Raw Materials:Ceramic Fiber Products for Heat Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ceramic fiber products

1.Type:1100/1260/1300/1430 degree centigrade

2.Density:96/128/160 kg/m3

3.Certificate:ISO9001 ,MSDS

Heat Insulation Ceramic Fiber Products

About ceramic fiber products

Ceramic Fiber Blanket is made form common,high pure, high aluminum and zirconium

alumina silicate fiber bulk. Its processes include needing, thermal forming,vertical and

transverse slitting and rolling.

Ceramic fiber blanket is ideal thermal insulation material, fire-proof material and sound-absorbing material. Needled-fiber blanket has even texture and smooth surface.

Characteristics of heat insulation ceramic fiber

1. low thermal conductivity ,low heat capacity

2. excellent heat stability and thermal shock resistance

3.good performance of thermal insulation, fire-proof and sound-absorbing

4. ultimate tensile strength

5. no delamination

Applications of heat insulation ceramic fiber

1.Industrial furnace, heating devices, high temperature pipe

2.High building fireproof ,sound-absorbing and thermal insulation material

3.Thermal insulation material for the electricity boilers, gas turbine and nuclear power.

4.Wall linings of the chemical high-temperature reaction equipment and heating equipment.

5.Thermal insulation for the furnace door and roof.

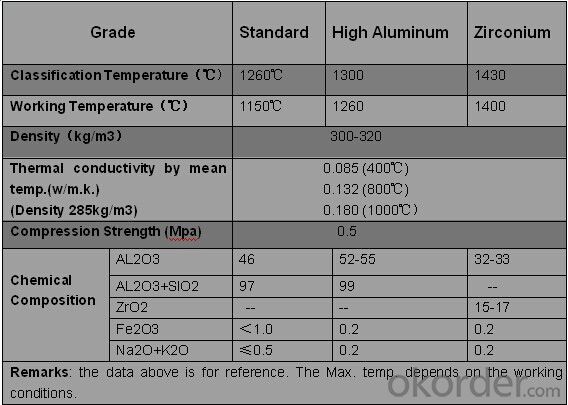

Technical data of heat insulation ceramic fiber

- Q: Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- Steel structure with heat galvanization has a process requirement, which is to spray fireproof coatings. Fireproof coatings have different functions and purposes from galvanized process. When the steel surface derusted, it generally needs to brush rich-zinc primer before spraying fireproof coating. Fireproof coating plan itself includes anticorrosion plan, and fireproof coating is just a layer of coating plans, which is an intermediate layer in general. Fireproof coating plan generally includes primer, fireproof coating and finishing paint. Some fireproof coatings can be directly painted on the bare steel elements without primer and finishing paint.

- Q: how about the performance of aluminum silicate fire proof thermal insulation?

- aluminum silicate fire proof thermal insulation board has a good performance. it is a artificial board that separates the wood and plant fiber by mechanical and chemical methods and mixed the adhesion agent and water-proofing?agent, molding by high temperature and high press. the density of fiber. tha above information is coming from the Internet and it is just for reference.

- Q: Concrete composition and function of magnesia bond used in refractory

- According to the chemical composition and use can be divided into metallurgical magnesia, magnesia brick, magnesia brick, magnesia brick, magnesia calcium brick, magnesia brick and other varieties. Its performance is greatly affected by CaO/SiO2 ratio and impurities. High purity magnesia brick refractoriness under load and thermal shock resistance are better than the general magnesia brick. High refractoriness, has good resistance to alkaline slag and iron slag, is a kind of important senior refractories. Use of magnesia product production by sintering process, sintering temperature is 1500 ~ 1800 DEG C, in addition, you can also add chemical bond, made of brick and unshaped refractory material. Mainly used in open hearth furnace, electric furnace, converter, oxidation non-ferrous metal smelting furnace, cement kiln and alkaline refractory kiln etc..

- Q: Who knows about the criteria of fireproof and thermal insulation materials?

- 1. thermal insulation materials with A-level combustion performance: EPS sea capacity module, rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. thermal insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), phenolic aldehyde, gelatine powder polyphenyl granule,etc. 3. thermal insulation materials with B2-level combustion performance: molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane(PU), polyethylene(PE), etc. Such A-level insulation materials are only fireproof, the thermal insulation properties are worse than that of organic XPS \\EPS materials. Currently I think that the best insulation material should be EPS sea capacity module, it not only achieves the requirement of insulation but also fulfills the goal of fireproofing, and the comprehensive unit price of it is not expensive. The thermal insulation materials in the domestic market have their own disadvantages, you'd better take the building demands into consideration, and use the materials that are within the acceptable range. I hope my answers help you.

- Q: Refractory factory grinding brick dust harmful to the body?

- The effect is very large and belongs to lung disease.

- Q: What are the fire resistances of grc partition panels?

- waterproofing: It has good water resistance; 2. fireproofing: fire resistance of partition panel≥3.5h, it has an excellent fireproof performance and can be applied to fire-proof bulkhead; 3.soundproofing: According to the different thickness of walls and surface treatments, perlite light partition panels insulation can be 40-50 decibels, to ensure that products can be used for office, commercial, entertainment and residential buildings; 4, light weight:

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Grade of fireproofing material: Class A: Incombustible building material, almost without burning. class A1: Non-combustible, no open flame,class A2: Non-combustible,it needs to measure smoke and be qualified. Class B1: Nonflammable building material: Nonflammable materials have good flame resistance function. when it contacts open fire or is under high temperature, it's difficult to burn and be spreading rapidly, and will stop burn after removing the combustion?source. Class B2: Combustible?building?materials: Combustible materials have good flame resistance function. when it contacts open fire or is put in the air at high temperature, it will immediately burst into flames, and easily result in the spreading of fire, such as wooden column, timber roof truss, timber beam, wooden stairs, etc. Class B3: Inflammability building materials, without any flame resisting effects, easy to burn, and has large danger of fire disaster.

- Q: what should be paid sttention when buying the refractory?

- solve the resources and the cost as much as possible. Accurate understanding and knowing the material temperature changes of various partsin order to choose the appropriate refractories. 4: 3, work performance, for example, take measures to ensure the overall life, and it is a very good buying principles: melting in high temperature metal erosion. These are the four major problems to consider when using refractory. You can choose low prices and low transportation costs of materials to meet the basic principles under the conditions described above. 2.carefully observe the material to prevent the desturction and reducing the costs. according to the structure of furnace, reasonable coordination of all parts of the material, fully take the advantages of material characteristics and strive to develop the recycle, to avoid the destruction of the materials.1. the working characteristics and the sport condition and analyze the reason of destroying the material, which can not only gurantee the product quality and reduce the expenses, get familiar with the chemical component and physics of the material.

- Q: It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

- Q: What are the specifications of fireclay bricks?

- Dimensions of refractory bricks : 230 * 115 * 65mm

Send your message to us

Refractory Raw Materials:Ceramic Fiber Products for Heat Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords