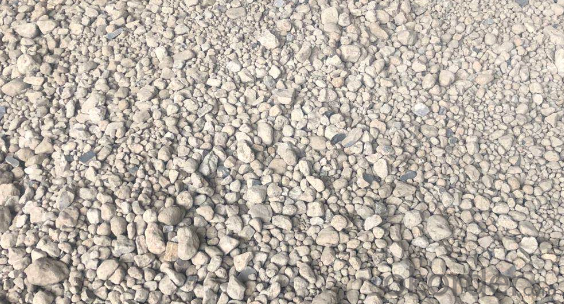

Raw Materials for Refractory:Refractory Grade Calcined Bauxite with Al2O3:86min in Lumps

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shanxi, China

· Shape: Block or grain size or powder

· Material: Alumina

· SiO2 Content (%): 4%-24%

· Al2O3 Content (%):70%-90%

· MgO Content (%):+CaO 0.8%MAX

· CaO Content (%):+MgO 0.8%MAX

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: Calcined bauxite

· Color: Gray or Cyan

· Size:50MESH/100MESH/200MESH/325MESH/0-1MM/1-3MM/3-5MM/0-40MM

· BULK DENSITY:2.6-3.3G/CM3

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q: What's the maximum temperature that the high-temperature resistant refractory ceramic fiber cotton can endure?

- Nichrome wire, stainless steel wire and glass fiber are reinforced. Ceramic fiber coating cloth and slag cloth, sintering ceramic fiber cloth and ceramic fiber fumigation cloth) Characteristics of the ceramic fiber cloth: high temperature resistance, low heat conductivity, thermal shock resistance, low thermal capacity; superior insulating property at high temperature, long service life; resistance to nonferrous metals like molten aluminum and zinc erosion; low and high temperature strength; innocuity with no adverse effect on the environment; Applications of ceramic fiber cloth: It can be applied to the thermal insulation of all kinds of furnaces, high-temperature pipelines and vessels; furnace doors, valves, flange seal, fire doors, fire resisting shutters and high-temperature furnace door curtains; engine and instrument insulation, clad material of fireproof cables, and high-temperature resistant and fire-proof materials; thermal insulation cloth for coverage, high-temperature expansion gap padding, and inner linings of the flue; high temperature resistant labor safety products, fireproof suits, high-temperature filtration and sound absorption, replacement of asbestos, etc.

- Q: What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q: Are the specification of fireclay bricks and ordinary clay brick the same?

- Do you want to know whether the specifications of fireclay bricks and ordinary clay brick are the same?

- Q: Does anyone know what kind of light fireproof materials are there?

- 二, 1, Gypsum plaster board With the building plaster as main raw material, gypsum plaster board is a kind of processed plate made by a special board for protective with an addition of additives and fibers as board core. Gypsum plaster board is characterized by light weight, sound insulation, heat insulation, strong processing performance and simple construction method. 2, Gypsum block Gypsum block is a kind of lightweight building gypsum product which is mainly made of building gypsum, and by adding water, stirring, casting and drying. During the process, , the fiber reinforced materials or light aggregates are allowed in, and the foaming agent can also be added. It has many advantages, such as sound insulation and fire prevention, convenient construction and so on. It is a kind of new and healthy wall material which produces low carbon, enhances environmental protection, and caters to the the times. 3, Fly ash brick is a new type of wall material, and bulk density is one of the main technical indexes. The weight of bulk density can be controlled according to the need of construction and adjustment of technical formula. The dry bulk density of the fly ash brick is about 1540 to 1640 kg / m 3, slightly lighter than the clay brick (1601800 kg /m 3). The flexural and compressive strength of fly ash brick is mainly determined by the production process, the formula and the hydrothermal synthesis reaction mode as well as the need of construction. According to the standards of architectural material industry (JC239 - 2001) released by People's Republic of China, the average value of the flexural strength is 2.5 ~ 6.2Mpa, compressive strength is between 10 ~ 30Mpa. I hope this will be helpful to you

- Q: What are the insulation fireproofing materials?

- Insulated shoes, insulated gloves, tape (cloth, plastic, as well as waterproof) yellow wax tube, mouth care, fireproof (ie asbestos cloth is sold by jin) there is pressure-caps black tape, waterproof tape ,casing. There are glass fiber needle felt is widely used in electrical, chemical, construction, transportation, automotive and other industries interlayer insulation and silencer system, and used as an insulating fireproof material.

- Q: What are the characteristics of clay refractory materials?

- Clay refractory has excellent performance in anti fatigue. The fatigue strength of the general metal is 50% ~ 40 of the tensile strength, and some composite materials can be as high as 70 ~ 80%. The fatigue fracture of the composite is from the matrix, which is gradually extended to the interface between the fiber and the matrix. Therefore, the composite material has omen before destruction, and it can be checked and remedied. Fiber composite material also has good performance in anti vibration fatigue. The fatigue life of The helicopter rotor made of composite material is longer that made of metal. I hope my answer will help you!

- Q: What are the fireproofing materials of the external wall included?

- According to the external wall thermal insulation materials, the external insulation materials is in general divided into Class A and Class B. The A class is non-combustible material. The B class is combustible materials. The fire disasters of the CCTV building and Shenyang hotel are both caused by the B level materials. Generally, the A level material will be used, and some prices are even cheaper than the B-grade material. A level is roughly divided into thermal?mortar, phenolic foam Board, rock wool board, foam cement board, and so on. I hope my answer will help you!

- Q: How many levels are there in the classification of PP fireproof materials?

- The level of fireproof materials: A-level: Non-combustible building materials have rare chance to burn. A1-level: Non-combustible materials, no open fire A2-level: Non-combustible materials, smoke should be tested and qualified. B1-level: Fire-retardant building materials: Fire-retardant materials are good at resisting flame. It is difficult for them to burst into fire when coming across open fire in the air or at high temperature. It will not quickly get wilder and when the fire source removes, it will be extinguished immediately. B2-level: Combustible building materials: Combustible building materials can play a certain role in preventing combustion. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden pillars, roof frames and beams as well as stairs. B3-level: Inflammable building materials are highly flammable with no flame retardant ability, fire risk is high.

- Q: What kinds of refractory materials that can resist 3,000 Celsius degree?

- steel fiber reinforced spalling resistant bricks, phosphate bonded high alumina brick with high strength and wear-resistance, and high R.U.L bricks and composite bricks

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite with Al2O3:86min in Lumps

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords