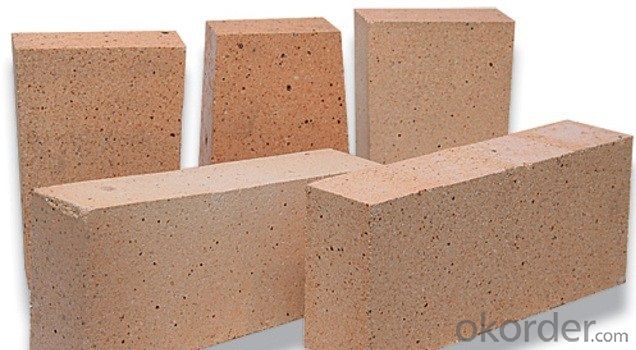

Fireclay Brick RN-42 - Refractory Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Fireclay |

| SiO2 Content (%): | standard international | Al2O3 Content (%): | 48max | MgO Content (%): | standard international |

| CaO Content (%): | standard international | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | standard international |

| SiC Content (%): | standard international | Model Number: | RN42 | Brand Name: | ANNEC |

| Name: | Clay Brick For Furnace | Apparent porosity: | ≤22 | Bulk denisity: | ≥2.15 |

| Creep rate: | ≤1.0 | Refractoriness: | ≥1750 | Refractoriness Under Load: | standard international |

| Permanent Linear Change: | standard international | Cold Crushing Strength: | ≥30 | Fe2O3: | standard international |

| Al2O3: | 48max |

Packaging & Delivery

| Packaging Details: | standard fumigate pallet for sea transportation |

| Delivery Detail: | 40 days after signing the contract |

Specifications

refractory fireclay brick RN-42

1.NASDAQ listed company

2. stock code: ANNC

3.exported to many foreign countries

4. pass ISO

Product Description

| Product name | Clay Brick | mark | ||||

| Items | Apparent porosity(%) | Bulk density(g/cm3) | creep rate(1250°C,20-50h,0.2MPa)% | Refracoriness(°C) | Refractoriness under load(0.2MPa)(°C) | |

| Speification | ≤24 | ≥2.15 | ≤1.0 | ≥1750 | - | |

| Items | Permanent linear change(1150°C,4h,average) | Cold crushing strength(MPa) | Thermal shock resisitance (1100°C,water)cycle | Al2O3(%) | SiO2(%) | Fe203(%) |

| Speification | - | ≥30 | - | - | _ | - |

We can do different components of low creep brick, Fireclay brick is refractory clay and flint clay clinker as the main raw materials, containing 30% to 46% alumina, refractoriness 1580 ~ 1770 °C, is a weak acid refractory, thermal shock resistance and the acidic slag corrosion resistance.

Our Services

& High professional services.

& Your private information will be well protected.

& After receiving the e-mail reply as soon as possible.

& We have a high-quality after-sales service

FAQ

Client:what is your company advertage?

Us:1, Our company has established a complete quality assurance system,we have been certified by an array of ISO.

2, There is almost no black spot on the surface of our bricks. It represents more even and neat color due to the superior raw material and strict selection.

3, Our product enjoys higher refractoriness under load because of its higher heat treating temperature in the high temperature zone of the furnace.

Client :why should we choose you?

Us:we can ensure qualified products only and 100%exfactory pass rate.

- Q: What is the name of the white clay refractory brick

- The name of white clay is kaolin clay

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What is the specific heat of a refractory bricks (clay)?

- Approximately it's about 2000; M3 specific heat is wrong with this argument, two degree clay is 1730 degrees, three degree clay is 1690 degrees, clay bricks are mixture, bulk density, 1900KG/, only elementary substance has specific heat refractoriness.

- Q: What are the release agents of refractory bricks?

- Alkalinity, the production process of alkaline, acid and alkali resistant transparent instant thickening powder, you can adjust the proportion according to the cost and needs of quality, environmental protection: One: Add the preservative into water to mix, after soaking one hour, then mixing evenly the production ratio, and then add the super core release agent into water to mix, add flavor pigment masterbatch into water to mix with water mixing, ensure completely dissolved, then add the waste oil, falvor is appropriate amount= release agent. Two, the newest recipe of release agent super core release agent masterbatch, waste engine oil, water, instant acidproof and alkaliproof transparent thickening powder, wire drawing powder, preservative, flavor and pigment= release agent super core wire drawing powder with water mixing, it is the most newly developed special core masterbatch and engine oil of Chengdu Hengfeng Hongye detergent factory, and it doesn't contain toxic solvents, especially 1, it has the following features, after thickening more than half an hour or so, mix evenly is ok, in a few seconds will waste oil and alkali: 10% of waste engine oil, 20% of release agent core masterbatch, 88% of water, 500g instant acidproof alkaliproof transparent thickening powder, 80g wire drawing powder, 1g pigment and preservative and lubricating oil and industrial grease, these integrate with water.

- Q: The furnace refractory bricks are burnt into ash, what material can resist higher temperature than the refractory brick

- refractory bricks, common clay brick, clay brick, high alumina brick and corundum brick

- Q: Is the quality of refractory brick influenced if it is soaked by water

- Refractory bricks shouldn't be got wet by damp. Other refractory brick is not much problem, after touching, please wash hand, or masonry stove ignition will burst. In addition, refractory bricks containing chromium can't meet water, it's easy to hydrate and scrap, it will generate Cr VI ( chromium VI ), which is hanrmful to health and pollutes the environment, but try not to get wet

- Q: What building materials can take the place of clay bricks?

- Housing grades have been upgraded, heat preservation, sound insulation, heat insulation, seismic, energy-saving performance fully reflected, can improve the selling point of commercial housing 3%, in the major cities in China has become the preferred condition of user purchase.

- Q: What is the size of mechanism brick and general refractory brick?

- The ordinary refractory brick is 230mm long, 53mm thick; red brick is 240mm long, 115mm wide, 65mm thick,

- Q: The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

- Q: What are the main constituents in non clay brick sintering?

- Unfired bricks are bricks used to build walls relative to sintered bricks.

Send your message to us

Fireclay Brick RN-42 - Refractory Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords