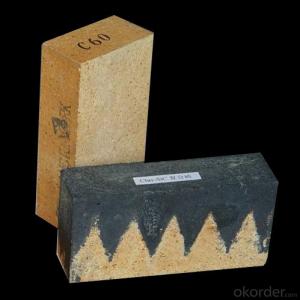

High Alumina Brick - Refractory Fire Brick Magnesia Alumina for Furnace Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Refractory Fire Brick

Refractory Fire Brick Magnesia Alumina for Furnace Liner is widely used in metallurgy, petroleum, chemical industry, building materials, machinery processing, military, etc of thermal technology equipment. Refractory Fire Brick is widely used for MgO Reduction Furnace, Blast furnace, Hot Blast Stove, Tunnel kiln , Steel Ladle, Steel smelting furnace, Coke oven,chimney, Waste incinerators, Casting products, Boilers, Cement kilns, Carbon furnace, Glass kilns and a variety of furnace linings and thermal equipment.etc.

Specifications for Refractory Fire Brick

Item | Refractory Fire Brick Magnesia Alumina for Furnace Liner |

Type | Silica alumina refractory brick Alkaline series Carbon brick Containing zirconium refractory brick Heat insulation refractory brick |

Size and Specifications | NA RNA NK NKI |

Characteristics | Density huge , Strength high Refractoriness under load high Thermal shock resistance best Good eroding resistance Resisting high temperature |

Typical Application

| 1.Building material industry,kiln,heating equipment and the inwall of high—temperature pipe line 2.Chemical industrial high temperature of reaction equipment inwall 3.Power plant ,gas turbine engine and heat insulation of unclear power 4.The fire proof of high—rise building 5.Furnace door of kiln 6.High-temperature filter material |

Operating Temperature | 600°C, 950°C |

Service | the specifications of refractory brick could be customized |

MOQ | 1 ton |

Port | Qingdao Port |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash |

Packing | wooden pallets with water-proof cover, and tightened with plastic/steel bandages |

Delivery | Within 15 Days |

Certificate | CE, ISO 9001 |

Features of Refractory Fire Brick

Low bulk density, low thermal conductivity, good thermal insulation performance.

Refractory category allow direct contact of fire, suitable for various atmosphere.

Good integrity with furnace lining, long service life, easy operation, could be shaped freely.

Typical Application of Refractory Fire Brick

Furnaces of metallurgy industry, heat treatment furnace.

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace .

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- In short, the overall market of refractory enterprises is in a turbulent adjustment process, but the volume is still in place. Elimination is inevitable, as to how many can be eliminated, dare not assert.

- Q: What is the difference between corundum and high alumina??

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.

- Q: The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q: What's the price of high alumina refractory bricks?

- Their refractory bricks are of good quality and low ex factory prices. Special high alumina refractory brick factory price of 1900 yuan / ton, a high alumina brick factory price of 1650 yuan / ton... This price applies to standard size, size 230*114*65mm, more products, prices go to see.

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The emphasis is on the physical and chemical indexes of low creep and high alumina bricks. The physical and chemical indexes of the high alumina bricks are different, too. They are DRL-1550And LZ-75 perform GB GB/T2988-2012

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Brick - Refractory Fire Brick Magnesia Alumina for Furnace Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords