Alloy Steel Billets 3sp/5sp Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Various Standards Mild Steel Billet, Square Billet

1.Specifications

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled, Continuous casting and rolling |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

2.Steel Grade:

Steel Grade | C % | Mn % | Si % | S % | P % |

Q195 | 0.06-0.12 | 0.25-0.50 | 0.30 Max | 0.04 Max. | 0.04 Max. |

Q235 | 0.12-0.22 | 0.30-0.60 | 0.30 Max. | 0.04 Max. | 0.04 Max. |

Q255 | 0.18-0.28 | 0.40-0.70 | 0.30 Max. | 0.045 Max. | 0.050 Max. |

Q275 | 0.27-0.38 | 0.50-0.80 | 0.30 Max. | 0.045 Max. | 0.045 Max. |

3SP | 0.14-0.22 | 0.40-0.85 | 0.15-0.30 | 0.050 Max. | 0.040 Max. |

5SP | 0.28-0.37 | 0.50-1.00 | 0.15-0.30 | 0.050 Max. | 0.040 Max. |

20MnSi | 0.17-0.25 | 1.00-1.60 | 0.40-0.80 | 0.050 Max. | 0.050 Max. |

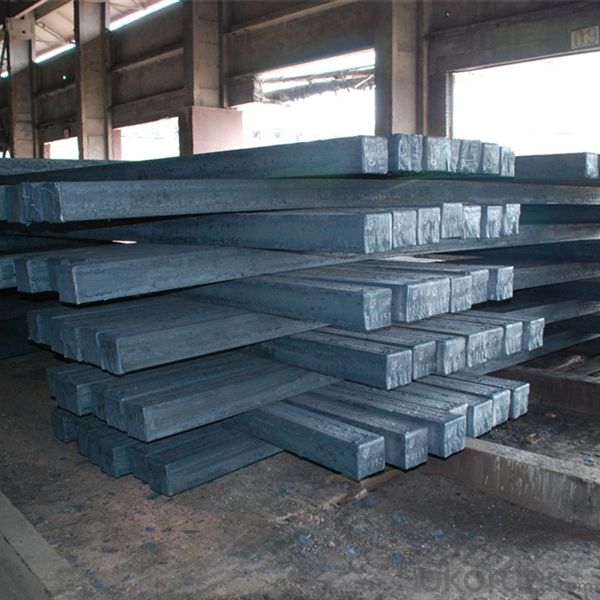

3. Products Picture

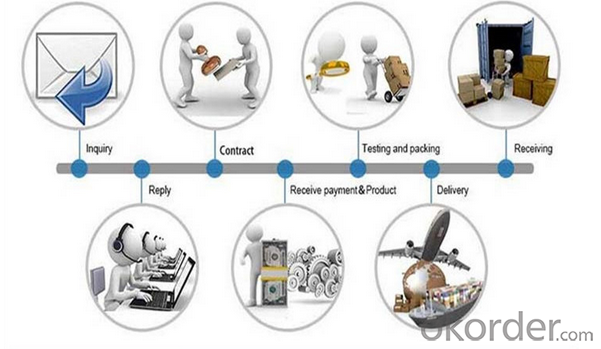

4.Trading Process

5.Why choose us:

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade team

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

- Q: What are the different types of steel angles and their applications?

- There are several types of steel angles commonly used in construction and manufacturing. These include equal angles, unequal angles, L-shaped angles, and T-shaped angles. Equal angles have equal leg lengths and are often used in structural applications, such as supporting beams and columns. They provide stability and strength, making them suitable for various load-bearing purposes. Unequal angles have different leg lengths and are commonly used in situations where additional strength or support is required. They are often used in framework construction, bracing, and as support brackets. L-shaped angles, also known as angle irons, are versatile and widely used in various industries. They are commonly utilized as structural elements, framing components, and supports for shelves, tables, and furniture. T-shaped angles, also called T-sections or T-bars, have a cross-shaped profile. They are utilized in construction and engineering projects that require additional strength and stability, such as in the construction of bridges, buildings, and machinery. Overall, the different types of steel angles offer a range of applications, including structural support, framework construction, bracing, and reinforcement in various industries.

- Q: What are the applications of steel grating in industrial platforms?

- Steel grating has various applications in industrial platforms due to its durability, strength, and versatility. It is commonly used as flooring material in industrial platforms to provide a secure and stable surface for workers. Steel grating offers excellent load-bearing capacity, allowing it to withstand heavy equipment, machinery, and foot traffic. Additionally, it provides effective drainage and ventilation, preventing the accumulation of water, debris, and hazardous gases. Its anti-slip properties further enhance worker safety in industrial environments. Overall, steel grating is essential in creating robust and reliable platforms that optimize productivity and safety in industrial settings.

- Q: How do steel products contribute to the construction of theaters and concert halls?

- Steel products contribute to the construction of theaters and concert halls in various ways. Firstly, steel is commonly used for the structural framework of these buildings, providing strength, stability, and the ability to span large distances. Additionally, steel is used for roofing, cladding, and facade systems, offering durability and aesthetic appeal. Steel is also utilized in the construction of balconies, stairs, and seating structures, ensuring safety and comfort for the audience. Overall, steel products play a crucial role in creating modern, functional, and visually appealing theaters and concert halls.

- Q: What are the different types of steel roofing materials?

- There are several types of steel roofing materials available, including corrugated steel, standing seam steel, and stone-coated steel.

- Q: How are steel products used in the construction of airports and terminals?

- Steel products are extensively used in the construction of airports and terminals due to their strength, durability, and versatility. Steel is used for structural frameworks, such as beams and columns, providing the necessary support and stability for large-scale airport buildings and terminals. It is also used for roofing systems, hangars, and canopies, ensuring protection from the elements and creating functional spaces. Additionally, steel is commonly employed in the construction of runways, aprons, and taxiways, as it can withstand heavy loads and provide a smooth surface for aircraft operations. Overall, steel products play a crucial role in the construction of airports and terminals, contributing to their safety, efficiency, and long-lasting performance.

- Q: How do steel products compare to other materials in terms of strength and durability?

- Steel products generally have higher strength and durability compared to other materials. Steel is known for its exceptional strength-to-weight ratio, making it suitable for a wide range of applications. It can withstand heavy loads, resist deformation, and maintain its structural integrity even under extreme conditions. Additionally, steel is highly durable, as it is resistant to corrosion, fire, and other forms of wear and tear. These qualities make steel a preferred choice in various industries, including construction, automotive, and manufacturing.

- Q: How is steel pipe coated for underground installations?

- Steel pipe is typically coated for underground installations using a process called fusion bonded epoxy (FBE) coating. This involves applying a powdered epoxy resin to the cleaned and preheated pipe surface, which then melts and forms a tough, corrosion-resistant coating upon cooling. This coating provides excellent protection against underground conditions and helps extend the lifespan of the steel pipe.

- Q: How are steel beams used in building structures?

- Steel beams are used in building structures as load-bearing elements that provide strength and stability. They are commonly used in the construction industry due to their high strength-to-weight ratio, allowing for the creation of large, open spaces without the need for excessive columns or supports. Steel beams distribute weight evenly, helping to support the weight of floors, walls, and roofs, and can withstand significant forces, such as wind and earthquakes. They are essential in constructing high-rise buildings, bridges, and industrial structures, where durability and structural integrity are paramount.

- Q: What are the uses of steel wire mesh?

- Steel wire mesh has a wide range of uses, including reinforcing concrete structures, providing security in fencing and gates, preventing animals from entering certain areas, filtering and sieving materials, supporting and reinforcing walls and ceilings, and creating partitions or barriers in construction and industrial applications.

- Q: What are the applications of steel in the mining industry?

- Steel is widely used in the mining industry for various applications. It is used in the construction of mining equipment, such as drills, shovels, and crushers, due to its strength and durability. Steel pipes and tubes are used for transporting and circulating fluids, such as water, chemicals, and minerals, within mining operations. Steel is also used in the construction of mine shafts, tunnels, and support structures to ensure safety and stability. Additionally, steel is used in the production of conveyor belts, screens, and sieves to facilitate material handling and processing in the mining industry.

Send your message to us

Alloy Steel Billets 3sp/5sp Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords