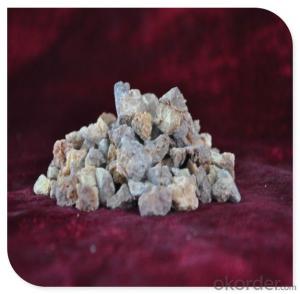

Refractory Raw Materials - Dead Burnt Magnesite MgO 90%

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DBM-is produced using selected natural magnesite that is purified and is calcined in a shaft kiln.The final product is used for electric furnacefloors and furnace liner tamping.

Many typical specification as following :

Grade | MgO (min.) | SiO2 (max.) | CaO (max.) | Fe2O3 (max.) | Al2O3 (max.) | L.O.I. (typical) |

mesh |

DBM90 | 90.00% | 1.00% | 1.50% | 0.70% | 0.10% | 1.70% |

0-400 |

DBM95 | 95.00% | 1.00% | 1.50% | 0.80% | 0.10% | 2.60% | |

DBM96 | 96.00% | 1.50% | 2.50% | 0.80% | 0.30% | 2.90% | |

DBM97 | 97.00% | 3.00% | 2.50% | 0.80% | 0.30% | 3.40% |

Packaging & Shipping of DBM :

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Application of DBM:

1.Mainly used in processing raw materials of different magnesia refractory,

2.The production of steel lining the bottom and ramming mixes;

3.The raw materials of magnesia brick and magnesia-chrome brick;

4.Used electric steel making furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages:

1) We have subsidiary plants doing metallurgical materials;

2) For some product, we do trading, while we can control the quality and cost due to our strong capacity and cash flow in China;

3) Our logistics and freight charge is lower than others since we have big quantity cargo to be exported in some main ports China;

4) We have strict and mature quality and logistics control on the cargo;

5)As a governmental company, we are reliable.

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of A grade fireproofing glass doors should be no less than 3 hours. A grade fireproofing glass doors use common glass of 6 mm. The shock resistance of float glass is about less than 5 min, and that of toughened glass is about 15 to 30 min. Fireproofing glass is classified in accordance with fire rating, the fire endurance of which is usually from 30 to120min, and that of the most common fireproofing glass is 60 to 90min, but now the market is a mixed bag, the so-called fireproofing glass is generally fake ultra-strong tempered glass. Therefore, you should buy the genuine glass with formal certificates, or you will bring yourself great inconvenience, and even more serious consequences.

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. (I hope this answer can help you!) Hope you adopt !)

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- Seven characteristics of insulating brick:Insulation and heat insulation: effectively reduce energy consumption.Fire prevention: up to national standard or class A.Clean and environmental protection: no two pollution will be caused by air.Per square metre weighs only about 1.4 kilograms, reduce the burden of building.Simple production: completely break through the traditional process, greatly shorten the construction cycle.Beautiful: can be modulated into a variety of colors, suitable for Ming outfit.Durable: long service life.

- Q: What's the function of aluminium dihydrogen phosphate on the refractories?

- Mainly used for binder of high-temperature furnace refractory. Characteristics of liquid aluminum dihydrogen phosphate, castable. solid used for refractory spraying coating, chamotte, ceramic construction, which has high break resistance after being dried in 350-500 ° C, phosphate bricks. Characteristics of the solid aluminum dihydrogen phosphate, binding agent used for castable and casting industry: together with the refractory aggregate, ramming mixes at room temperature: Easy to mix, crush resistance, hydration resistance, chamotte, will not become soft even if soaked or boiling in water, molding. Liquid use refractory spraying coating, mainly used for corundum, chrome corundum water gap in refractory industry. The production of chrome aluminum zirconium corundum brick for water-coal-slurry gasifier is especially suitable for site construction applications mainly used for the electrical industry, high-temperature kiln and furnace, hardener, after mixing between 90-110 ° C for 4-24 hours at a constant temperature, forming strong bonding strength, electrical insulation, heat treatment resistance furnace

- Q: Who can tell me about the foundry refractory materials?

- The casting fireproof materials can be divided into three categories in accordance with chemical property, namely, acidic, neutral and alkaline refractories. The commonly used refractories are alkaline and neutral ones, such as alkalic magnesia-carbon bricks, fired magnesite bricks, magnesia-chrome bricks, magnesium-calcium bricks, and neutral high alumina bricks, corundum brick, clay bricks, etc. The shapeless ones include: castable refractory, ramming?mass, gunning mix, coating, and dry vibration material, etc!

- Q: Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on. The judgment condition of the fire resistance There are three conditions for components' fire resistance limit to be reached, namely, the fire resistance limit of the building component: Loss of support and integrity; loss of time to fire the role of the time; as long as any of these three conditions is met, it will reach its limit of fire. Hope my answer will help you.

- Q: Who knows that among refractory materials, insulation boards from which refractory material industry is superior in quality?

- Using high temperature insulation material during casting process .In the molding, assembly the insulation?board on the ingot head or install heat insulation cap . There are three ways to install the molded steel insulation board and install insulation?board on at the head of the ingot, namely, clamping, nail fixation and mosaic technique.Compared with clay-based liner, the use of insulating board will improve high steel billet rate up to about 5% to 10%.

- Q: whether the aluminum silicate thermal insulation material is fireproof or not?

- Yes, it is fireproof. Refractory thermal insulation material mainly refers to the inorganic thermal insulation materials and composite thermal insulation materials. According to the shape it can be divided into: Fibrous finishing, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber,ect.. it takes the flint clay clinker as raw material, produced by the fusion of resistance or electric arc furnace and the injection of fiber forming. characteristic: Low thermal conductivity, excellent thermal and chemical stability, without binder and corrosive material.

- Q: What refractories can withstand high temperature above 2100 degrees?

- You can refer to advices from the first one coupled with the second one.

- Q: What are the material requirements of class A fire resistant door ?

- Grade A fire resistance steel door, namely steel wooden doors or steel-wooden composite door, including reinforced wooden door, is usually used in indoor. In fact, it is the door with steel bar inside and density board or blockboard outside.

Send your message to us

Refractory Raw Materials - Dead Burnt Magnesite MgO 90%

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords