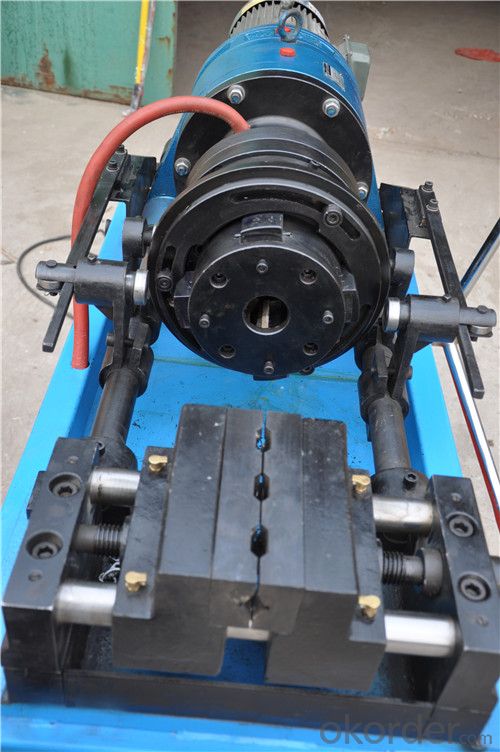

Rebar Taper and Parallel Threading Machine / Threading machine AGS-40

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rebar Taper and Parallel Threading Machine / Threading machine AGS-40

Specification

Application

Advantage

T/T L/C

7-15 working days

Beijing

- Q: How does operating machinery under water complicate mining procedures?

- Absolute pressure at the surface is 14.7psi. Absolute pressure at 250 feet of see water for example is 126psi. That puts the machinery and people into a very different world that us surface dwellers from the get go. The BP job was at something like 7000 to 8000 feet if I remember correctly. That's about 3352psi. People can only dive to about 1000 feet of sea water. So on the BP job there were no people down there working. Everything we saw was from ROVs. Remotely Operated Vehicles. Doing things with a claw that is controlled by a joystick through a TV screen is very different from doing it with your own hands when you're right there looking at it. Even when you do have divers down there they usually only have 1 to 4 people. That's a limited team. They do not have a big box full of tools down there with them. They have the surface crew send the tools to them as needed. Salt water is not good for any kind of tool. It makes them rust and makes the seals break down. This leads to tool failure and many trips back and forth for replacements and repairs. The surface crew is usually young guys 18 to 25 who are not the most mature or reliable people in the world. Tool maintenance does not always get done properly. Divers are regular people. They are stubborn, arrogant, lazy, dumb and any other thing that you run into with coworkers anywhere. If they feel like sitting down for a break, the boss can't always keep a proper watch on them or come down and yell at them. We just finished a well abandonment job where we did the same thing with plugging a well with concrete just like the BP job and it took us 6 tries. That technique doesn't work too good at shallower depths either. This stuff is still full of bugs buts the pursuit of money keeps things moving beyond what we truly understand.

- Q: I am need to sell some used machines and tools for parts. Anyone know of where I can post and auction/sell them online?That is not EBAY!

- Amazon??

- Q: Is machinery still being built?

- yes it is

- Q: I'm not very fond of walking on the treadmill for half an hour or going to the gym and using those big, scary machines. O.oBut I really want to lose weight and stay healthy, just without all that metal tearing me apart. What kinds of exercises are best for losing weight without the use of machines?

- I go on walking trails.

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: I have a chance to get a machiery sales job (territory representative for heavy machinery equipoment sales).Since i had no much experience in this domain, i was hoping that somebody can give me tips (general tips) on how to do first sales calls and visits?How should i present myself and how to avoid sounding like telemarketer :)

- try craigs list

- Q: What would happen if machinery is sold for less than book value?

- Short answer, you have a book loss. Long answer, first we can make no tax assumptions here, not enough info. But for book value, I assume you mean the value on the books of whoever owned it before the sale. If you sell something for less than than the value on your books, you have a book loss. For instance, you bought a computer for $900, intending to keep it for 3 years. After the end of the first year, after a full year depreciation (straight line), the book value is $600. Let us say Dell comes out with something totally new and you want it. You buy it and want to get rid of your old one. But because of the new Dell almost everyone is buying, nobody really wants yours. You find someone to buy it for $200. Your book value was $600, you sold it for $200. You have a loss of $400. On your books is $900 debit to equipment and $300 credit to accumulated depreciation. So your entry to post the sale of your computer is this (Dr is debit, Cr is credit): Dr Cash $200 Dr Accumulated Depreciation $300 Dr Loss on Sale of Asset$400 Cr Computer $900 The entry balances.

- Q: Reconditions will do, will need some for places with dire needs

- The okorder /

- Q: machinery purchsed entry and derpeciation charged for it?

- The purchase: Dr. Machinery (Fixed Assets) Cr. Cash / Accounts Payable Depreciation: Dr. Machinery Depreciation Expense Cr. Machinery Accumulated Depreciation Note that the accumulated depreciation is a contra account for the fixed assets, and what appears on the Balance sheet is the net of the two figures.

- Q: Women: Do you like to operate machinery? Weedeaters? Lawnmowers? Tillers? Tractors? Etc?

- yea they are convient and allow the job to look its best

Send your message to us

Rebar Taper and Parallel Threading Machine / Threading machine AGS-40

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords