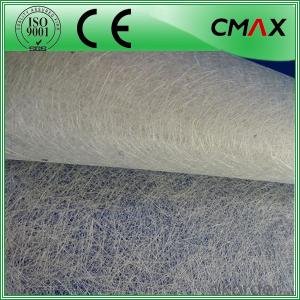

Ppg Chopped Strand Fiberglass Reinforced Raw Materials Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Chopped strand mat is made from chopped glass fibers, which are bonded with powder or emulsion binders. It can be used in hand lay-up process and continuous laminating process to produce FRP products, such as plates, lighting board, hull, bathtub, cooling towers, anti-corrosion materials, vehicles.

Features:

Uniform thickness, softness and hardness good.

Good compatibility with resin, easy completely wet-out.

Fast and consistent wet-out speed in resins and good manufacturability.

Good mechanical properties, easy cutting.

Good cover mold, suitable for modeling complex shapes.

Application:

fiberglass thickness is suitable for application by hand lay-up, reinforce and machine FRP molding,

including interior decoration of vehicles, boat hulls, complete set of sanitary equipment, anticorrosive pipes, tanks, building materials, tables, chairs, panels and all kind of composite FRP products.

Specifications:

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Special products are available according to customer’s requirement.

Product Packaging:

Each Surface Tissue is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 330mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Product Storage:

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

Order Information

Ordering please specify:

1. the product code, 2. weight, 3. width, 4. order quantity, 5. packaging, 6. special requirements please specify.

FAQ:

1. How long will you get reply?

Any inquiry will be replied within 24 hours. Usually we will reply within 12 hours.

2. How long is warranty period?

We provide 3 year warranty period.

3. What is your MOQ?

Any order quantity is available.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T, Western Union, Paypal etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

15-20 days for bulk production after confirm the order.

- Q: Is fiberglass chopped strand suitable for construction reinforcement applications?

- Construction reinforcement applications can benefit from the use of fiberglass chopped strand. This material is created by chopping fiberglass strands into smaller pieces, usually around 1 to 3 inches in length. These chopped strands are then mixed with a binder and molded into mats or sheets. The advantages of fiberglass chopped strand make it an excellent option for construction reinforcement. Firstly, fiberglass is known for its strength and durability, which enhances the overall strength of structures. It possesses high tensile strength and exceptional resistance to chemicals, corrosion, and weathering, allowing for its use in various construction applications. What's more, fiberglass chopped strand is lightweight, making it easier to handle and install compared to traditional reinforcement materials like steel. This can result in faster construction times and reduced labor costs. Moreover, fiberglass chopped strand is non-conductive and non-magnetic, making it ideal for situations where electrical conductivity or magnetic interference must be avoided. It is also non-combustible, providing an added level of safety in construction projects. In conclusion, fiberglass chopped strand is a versatile and dependable material for construction reinforcement. Its combination of strength, durability, lightweight nature, and non-conductive properties make it suitable for a wide range of construction projects.

- Q: The uses of middle alkali glass fiber chopping fabric?

- It is used for high quality asbestos tiles and glass fiber reinforced cement.

- Q: Is fiberglass chopped strand suitable for automotive interior panels?

- Yes, fiberglass chopped strand is suitable for automotive interior panels. It is a lightweight and durable material that offers excellent strength and dimensional stability. It is also resistant to heat, chemicals, and corrosion, making it ideal for use in automotive applications. Additionally, fiberglass chopped strand can be easily molded into complex shapes, providing versatility in design for interior panels.

- Q: What is the typical moisture content of fiberglass chopped strand?

- The typical moisture content of fiberglass chopped strand can vary depending on various factors such as storage conditions, manufacturing processes, and the specific type of fiberglass used. However, in general, fiberglass chopped strand is typically produced and maintained at a moisture content of less than 0.2%. This low moisture content is essential to ensure the optimal performance and stability of the fiberglass in various applications such as composites, insulation, and reinforcement materials.

- Q: How is fiberglass chopped strand used in the agricultural sector?

- Fiberglass chopped strand is widely used in the agricultural sector for various applications. One common use is in the manufacturing of livestock and poultry housing structures. The chopped strand is mixed with resin and applied in layers to create strong and durable panels, roofs, and walls for these structures. This helps provide a secure and comfortable environment for the animals while also being resistant to harsh weather conditions. Additionally, fiberglass chopped strand is utilized in the production of irrigation systems. The strands are mixed with other materials to create pipes, tubes, and tanks that are used for storing and distributing water in agricultural fields. These fiberglass-based irrigation systems offer excellent resistance to corrosion, ensuring the longevity and efficiency of the water distribution process. Moreover, fiberglass chopped strand is employed in the manufacturing of agricultural equipment such as sprayers, seeders, and fertilizers. The chopped strand is mixed with plastic resin to create strong and lightweight components, which enhance the overall performance and durability of these machines. This allows farmers to efficiently and effectively manage their crops, ultimately increasing productivity. Furthermore, fiberglass chopped strand is used in the construction of greenhouses and nurseries. The strands are mixed with other materials to create panels and roofing systems that provide optimal light transmission and thermal insulation. This creates an ideal environment for plant growth, protecting them from extreme weather conditions and ensuring their healthy development. Overall, the use of fiberglass chopped strand in the agricultural sector is diverse and essential. It plays a crucial role in creating durable housing structures for livestock, manufacturing efficient irrigation systems, producing reliable agricultural equipment, and constructing effective greenhouses. The strength, versatility, and resistance to corrosion make fiberglass chopped strand an ideal material for various agricultural applications, ultimately contributing to improved farming practices and increased crop yields.

- Q: Can fiberglass chopped strand be used in aerospace composites?

- Yes, fiberglass chopped strand can be used in aerospace composites. Fiberglass chopped strand is a common reinforcement material that is widely used in various industries, including aerospace. It offers excellent strength-to-weight ratio, chemical resistance, and thermal stability, making it suitable for aerospace applications where lightweight and high-performance materials are required. Fiberglass chopped strand can be used in the production of aerospace components such as panels, fairings, interior parts, and structural elements. It can be combined with other reinforcement materials, such as carbon fibers, to enhance the overall properties of the composite. However, it is important to note that the specific requirements and regulations of each aerospace project should be considered when selecting the appropriate reinforcement material.

- Q: What are the advantages of using fiberglass chopped strand over other reinforcement materials?

- Using fiberglass chopped strand as a reinforcement material has various benefits. First and foremost, it provides exceptional strength and durability. With its high tensile strength, it can withstand heavy loads and stresses without breaking or deforming. This makes it an ideal option for reinforcing materials and structures like concrete, plastics, and composites. Additionally, fiberglass chopped strand is lightweight, which sets it apart from other reinforcement materials such as steel or aluminum. Its reduced weight makes it easier to handle and transport, leading to lower labor costs and increased efficiency. Moreover, fiberglass chopped strand boasts corrosion resistance. Unlike metals like steel that can rust and deteriorate over time, fiberglass is not susceptible to corrosion. This makes it suitable for use in harsh environments or areas exposed to moisture, chemicals, or saltwater. Another advantage of fiberglass chopped strand is its electrical insulation properties. Being a non-conductive material, it does not conduct electricity. This makes it an ideal choice for applications where electrical insulation is crucial, such as electrical equipment, circuit boards, or wiring insulation. Furthermore, fiberglass chopped strand is highly versatile. It can be easily molded and shaped to fit various forms and configurations, allowing for customized designs and applications. Its excellent adhesion properties enable it to bond well with other materials, further enhancing its versatility. Lastly, fiberglass chopped strand is cost-effective. In comparison to alternative reinforcement materials like carbon fiber, fiberglass is generally more affordable. This makes it a cost-effective choice for many industries and applications, without compromising on performance and reliability. In conclusion, fiberglass chopped strand offers numerous advantages over other reinforcement materials, including excellent strength, lightweight, corrosion resistance, electrical insulation, versatility, and cost-effectiveness. These qualities make it a preferred choice in various industries, ranging from construction and automotive to aerospace and electronics.

- Q: Is fiberglass chopped strand suitable for electrical grounding applications?

- No, fiberglass chopped strand is not suitable for electrical grounding applications.

- Q: How does fiberglass chopped strand affect the strength of composite materials?

- Fiberglass chopped strand enhances the strength of composite materials by providing reinforcement and improved mechanical properties. The random orientation of the chopped strands helps distribute the load and prevents crack propagation, increasing the overall strength and durability of the composite material.

- Q: Can fiberglass chopped strand be used in water treatment applications?

- Yes, fiberglass chopped strand can be used in water treatment applications. Fiberglass is a versatile material that offers excellent resistance to corrosion and chemicals, making it suitable for use in water treatment processes. Chopped strands of fiberglass can be used to reinforce various components such as pipes, tanks, and filters used in water treatment systems. The high strength and durability of fiberglass make it ideal for withstanding the harsh conditions often found in water treatment facilities. Additionally, fiberglass is non-toxic and does not leach harmful substances into the water, ensuring the safety of the treated water.

Send your message to us

Ppg Chopped Strand Fiberglass Reinforced Raw Materials Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords