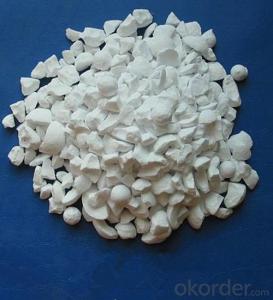

Raw Materials for Refractory:Tabular Alumina for High Quality Refractory Delivery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tabular Alumina

Specifications

Tabular Alumina is high purity alumina processed by CE Minerals.Used as refractory,abrasives,polishing,grinding,ceramics.

Advantages

High Purity & Good Quality.

Good Hardness & High Heat-resistance.

Competitive Price & Reputable Supplier.

Typical Size

48mesh 100mesh 200mesh -35mesh 0.1-0.3mm 0-1mm 1-3mm 3-5mm

Guarantee Value

Item | Unit | Index | Typical | |

Chemical composition | Al2O3 | % | 99.00min | 99.5 |

SiO2 | % | 0.20max | 0.09 | |

Fe2O3 | % | 0.10max | 0.07 | |

Na2O | % | 0.30max | 0.20 | |

CaO | % | 0.1max | 0.03 | |

MgO | % | 0.1max | 0.06 | |

R2O | % | 0.3max | 0.20 | |

Magnestic | % | 0.02max | 0.01 | |

Bulk density | g/cm3 | 3.50min | 3.59 | |

Absorbing water rate | % | 1.0max | 0.7 | |

Porosity rate | % | 4.0max | 3.00 | |

Grain size | mm | 5-3mm,3-1mm,1-0mm,2-1mm,1-0.5mm, 0.6-0.2mm,0.5-0mm,0.3-0mm, | ||

Fine powder | mesh | - 220mesh, -325mesh | ||

Applications

Refractories & Abrasives.

Polishing & Grinding.

Ceramic material.

Applicated for high temperature engineering equipment, construction materials.

- Q: What is the role of adding chromium oxide green in unshaped refractory materials

- Generally, less is added in corundum or corundum spinel refractory material, but it can significantly improve the material performance such as high temperature strength, erosion resistance, thermal and shock stability, etc.

- Q: How many kinds of fireproof materials are there in the market?

- rock wool board? inorganic thermal insulation mortar? glass wool board? expanded glass? ceramic foam plate? sand aerated concrete? haydite concrete? foam cement? vitrified micro bubble panel

- Q: Procedures for producing common refractory materials?

- The general procedures of producing refractory materials include calcination of raw materials, selection of raw material , crushing, grinding, screening, mixing, ageing mixture, molding, drying, burning and etc. At present, the refractory factory usually purchases the calcined clinker, so the calcination of raw material is no longer a consideration of common refractory plants.

- Q: Are the specification of fireclay bricks and ordinary clay brick the same?

- Do you want to know whether the specifications of fireclay bricks and ordinary clay brick are the same?

- Q: What type of firebrick does TZ-3 represent?

- It is the standard brick.

- Q: What are fireproofing materials?

- Class A incombustible material: Granites, marbles, terrazzos, cement products, concrete products, plasterboards, clay products, glass, tiles, mosaics, steel, aluminum, copper alloys; B1 class flame nonflammable materials: Ceiling materials: gypsum plaster boards, fibrous plasters, cement particle boards, mineral wool decorative acoustic panels, glass wool decorative acoustic boards, perlite decorative acoustic boards, flame retardant plywoods and medium density fiberboards, rock wool decorative panels, flame retardant woods, aluminum foil composite materials, flame retardant phenolic laminates, aluminum foil glass fiber reinforced plastic composite materials; Wall covering: gypsum plaster boards, fibrous plasters, cement particle boards, mineral wool boards, glass wool boards, perlite boards, flame retardant plywoods, flame retardant medium density fiberboards, fireproof plastic decorative plates, nonflammable double-sided particle boards, multicolor paints, nonflammable wallpaper and textile wall cloth, flame retardant simulated granite decorative plates, magnesium oxychloride cement prefabricated wall panels, flame retardant glass fiber reinforced plastic plates, PVC plastic clapboards, high-strength and lightweight composite wallboards, fire-retardant molded wood composite boards, flame retardant colored artificial boards, nonflammable glass fiber reinforced plastics, etc.

- Q: Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q: What is refractory cement?

- How to use exactly refractory cement? Someone professional advised me to buy this cement. Does it differ a lot from common cement? Is refractory cement expensive?

- Q: What are the new refractories?

- There are many of them. We can talk face to face. Sichuan Province Deyang City Xinxin Refractories Co. 0838-2228543

Send your message to us

Raw Materials for Refractory:Tabular Alumina for High Quality Refractory Delivery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords