Raw Materials for Refractory - Refractory Grade Calcined Bauxite Powder with Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Alumina Block |

| SiO2 Content (%): | 9% max | Al2O3 Content (%): | 85% min | MgO Content (%): | 0.1max |

| CaO Content (%): | 0.2max | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | Model Number: | BOSUN001 |

| Brand Name: | cnbm |

Packaging & Delivery

| Packaging Details: | Packing in 25kg bag or 1mt big bag. |

| Delivery Detail: | Within 20 days upon receipt of T/T prepayment or workable L/C. |

Specifications

1. Custom size

2. 85%min Al2O3

3. Premium Customer Services

4. Reliable Products Supply

5. ISO Certificate

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

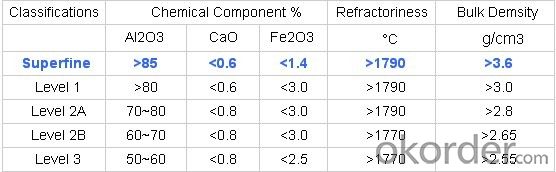

Calcined Bauxite Specifications

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: How many kinds of fireproof materials are there in the market?

- Inorganic insulation materials basically can achieve the goal, such as glass wool, rock wool, and foam glass. The phenolic foam in the organic foam material is special. Phenolic foam is not only good at insulation, but also good at compounding with steel and other materials to achieve A-level performance, and the A-level insulation materials are: rock(ore) wool, foam glass and inorganic thermal insulation mortar. Insulation materials with B1 combustibility mainly are: Phenolics, polystyrene granules, etc. The insulation materials of fire barrier zone can use such A-level materials as rock (ore) wool, foam glass, and inorganic thermal insulation mortar, etc.

- Q: Development trend of refractories

- Mullite Matrix clinker. There are higher requirements of kaolin and refractory annded life, it should be able to grind medical industrial raw materials alumina, vacuum extrusion molding, high temperature roasting and smelting from unshaped refractory material a good thermal mechanical properties in the kiln and has good application prospect; 2, Dong Qingshi clinker. With kaolin and magnesia as raw materials, wet grinding, vacuum extrusion, and then high temperature calcination, furniture has a very good prospect; 3, magnesium calcium sand. Because of the development of clean steel, low carbon steel, high oxygen steel and stainless steel, the basic importance of free calcium oxide refractories is supported; 4, fused eutectic composite. Bauxite based fused corundum, bauxite based fused mullite, bauxite based fused mullite zirconia, fused corundum zirconia fused zirconia, Magnesium Oxide and other materials have been developing rapidly; 5, high density spherical hollow mullite aggregate. The wall thickness of the shell of the 0.2 - 1.5 - 5 mm, diameter 40 mm, smooth surface, can not be uniform, spherical shell, this may be a double, a prominent part of the surface can be dense, can also be used for hollow casting material, not only can improve the insulation performance of the material, in order to reduce the volume density. Instead of destroying its strength.

- Q: Do you know the refractories?

- Definition of refractory: inorganic non-metallic material with fire resistance greater than 1580 degrees is refractory.Refractory material is a part of material industry. It is named refractory material for thermal kiln. Refractory materials are divided into conventional refractory materials and special refractory materials, and conventional refractory materials are used in metallurgical furnaces, cement kilns, glass kilns and other thermal furnace lining materials, mostly processed from natural raw materials. Special refractory materials are of high purity, mostly oxide synthetic materials, used in special smelting equipment, or special parts of kilns.

- Q: What are the requirements of the performances of brasque refractory?

- The requirements of the performances of brasque refractory: 1, should have sufficient refractoriness and softening point under a fixed load. Because under the action of the electric arc, the inner and surface temperature of the different parts of the brasque can be up to 1500 ~ 1800 ℃. 2, should have strong slag resistance. Because the inward permeation of slag and smoke at high temperature through its pores of brasque cause melting loss of refractories, organization delamination and flaking. 3, should have good thermal shock resistance. Because in the steelmaking process, opening the furnace door, lifting the furnace lid will cause sudden temperature change of brasque refractory,flaking and cracking, resulting in premature failure of brasque. 4, should have sufficient strength, because the brasque will be impacted at the time of loading, vibrated when tilting, flushed by metal, slag and gas flow when boiling. 5, the thermal conductivity and the conductivity should be small. Refractories commonly used for electric furnace include magnesia bricks, dolomite brick, high-alumina refractory bricks, silicious refractory brick and magnesite ramming material. Due to the different working environment of each parts of the furnace, refractories are different.

- Q: How much is the duration of fire resistance of the porous brick shale?

- This is really a simple question. The temperature should be limited within 1050℃, or it will be scorched. I think 980℃would be acceptable.

- Q: I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

- Q: What refractories are used in various parts of the blast furnace.

- Blast furnace from top to bottom has the throat, hearth staves, waist, bosh, hearth and furnace bottom. the specific structure is as follows: The throat is the first to be affected by the impact and abrasion, generally use high-density alumina bricks. the upper and central portion of temperature furnace is only 400 ~ 800 ℃, the area with high alumina bricks and silicate bricks. The lower part of furnace is subject to erosion and dust erosion alkali metal vapor due to high temperatures, it is required in such case to use high quality clay brick,high alumina brick,carborundum brick,corundum brick that is slag resistance and alkali?resistance, temperature resustant and wearproof. Furnace bosh temperature reached 1400 ~ 1600 ℃, serverly eroded by slag,vapor, flush. so we use carborundum brick and reaction-bonded silicon?carbide?brick. Bosh temperature reaching1600 ~ 1650 ℃, using alumina brick, corundum brick or silicon carbide brick. the temperature of Hearth near the upper portion of the outlet zone at 1700 ~ 2000 ℃, use of silicate bricks and corundum castable graphite filler, silicon carbide bricks. In 1450 Silly twitch bottom temperature sealing die of hunger slander bet phoenix astringent preserved Grade ~ 1500 ℃, use of graphite bricks and microporous carbon bricks, now use more corundum brick, corundum mullite brick and synthetic mullite brick. x26lt;P class x3d "share-btn"x26gt;

- Q: Is there anyone who can explain how to grade the level of fire insulation board?

- The classification of fire proof level for thermal insulating material 1, Burning performance of building material can be classified into the following several grade according to national standard GB8624-97: Non combustible building materials: Non-conbustible material. Class B1: Refractory building materials: Flame retardant materials have good flame retardant effect.

- Q: What 's the highest temperature can magnesium plate glass resist ?

- You just need a fire-resistance board thicker than 10 mm ,remember to add more perlite as filler during production , 12 mm plate is 80 yuan.

- Q: Are the rubber insulation materials are refractory materials?

- Bushi

Send your message to us

Raw Materials for Refractory - Refractory Grade Calcined Bauxite Powder with Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords