Raw Materials for Refractory:Low Iron Calcined Flint Clay

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

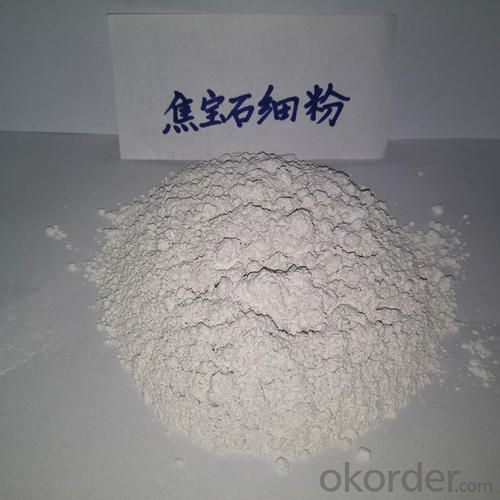

· Shape:particle or powder

· Material:Alumina

· Al2O3 Content (%): 45min

· Fe2O3Content (%): 2.0max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Flint Clay

· Color:White and yellow

· Size:100MESH/200MESH/0-1MM/1-3MM/3-5MM/0-40MM or as customer's request

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:particle or powder or clinker

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: What are the physical properties of refractory material?

- The mechanical properties of refractory material include compressive strength, volume density and sclerosing, slag resistance, elastic modulus, thermal shock resistance, oxidation resistance, bibulous rate, fluidity, resilience, bond strength and slump, electrical conductivity, specific heat, heat capacity, the impact strength, linear change, torsional strength, stomatal aperture distribution, resistance to acid, etc. The use performance of refractory material include refractoriness, thermal emissivity, condensation, porosity, coefficient of thermal expansion. Thermal properties of refractory material include thermal conductivity, temperature conductivity, plasticity, the hydration resistance, creep performance. The physical properties of the refractory materials include structure performance, mechanical properties, shear strength, load softening temperature, CO erosion resistance. The structure properties of the refractory materials include porosity, alkali resistance and sintering. The operating performance of refractory material include consistency, tensile strength, the use performance and operating performance, wear resistance, bending strength, thermal properties.

- Q: How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: What things and cement mixed can act as refractory?

- Cement acts as cementing material. Itself works by refractory aggregate and stir the refractory material for its gelling refractory aggregate both should be fire-resistant.

- Q: Does anyone know fire-proof material of fireproof wooden door?

- Fireproof wooden door goes through the flame treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method. Spraying method and soaking method are generally used for timber surfaces which are no longer going through planing process, and thin plate fire retardant treatment, whose thickness is less than 10mm .

- Q: What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q: What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material.

- Q: What types does refractory floor include?

- It includes ecoplates, chipboard,density board, composite?board, etc. Wherein ECO-plate is solid wood board, and it is environmetanl and healthy. Its nail-holding ability and flatness is much better than that of chipboard and solid wood particle board. After all it is solid wood board. But we must pay attention to whether the eco-board is produced in the original factory. According to our original factory, the board only produced by Treezo Group and Dede board are the original.

- Q: What is the biggest difference between refractory bricks and clay refractory bricks? Where can I find information on the refractory bricks?

- You can look up knowledge manual of refractory material to find phosphatic material, etc. Xinjiang refractory bricks, castable refractory, refractory material, silicious, corundum and alumina-magnesia: High alumina and clay refractory bricks can be divided into

- Q: Who knows how many poured refactory material are there?

- Casting refractory material, refractory material used often are AZS brick, corundum brick, direct bonding magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide brick, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, magnesium oxide, beryllium oxide and other refractory materials.

- Q: What refractory materials are used in power plant

- Vacuum mud machine, sintering furnace! And then I will introduce some application of thermal material in power plant (below) I hope I can help you. Energy saving is the trend of future industrial development efforts, grinding machine, conveyor belt, so the production of light thermal insulation materials will gain state support, drying kiln. Our factory mainly produce light thermal insulation brick. The refractory material we use most is light insulation brick, and the equipment used is sand mixer (Luohe, Henan)

Send your message to us

Raw Materials for Refractory:Low Iron Calcined Flint Clay

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords