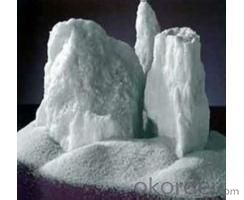

Raw Materials for Refractory:ISO Certified Low Na2O White Corundum/White Fused Alumina Grain with Al2O3 99.2 Min

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 1) 25kg woven bag 2) 25kg paper bag 3)1000kg big bag 4) According to clients' requirement. |

| Delivery Detail: | Within 30 days or depend on the requirement of clients. |

Specifications

White Fused Alumina grain with Al2O3 99.2 min

ISO9001 Certificated

Strong wear and heat resistance

1. Advantage

White fused alumina is made of quality alumina powder by smelting at 2050 °C.

1). High purity

2). Good self-sharpening

3). Less thermal diffusivity in grinding

4). Strong acid-alkali resistance

5).Excellent high-temperature stability,

6). Low porosity, etc

2. Available Size:

Refractory grade:

12-6mm 10-8mm 8-5mm 5-3mm 3-1mm 1-0mm 1-0.5mm 0.5-0mm 0.3-0mm....

80F 100F 120F 150F 180F 200F 240F 270F 320F/325F...

Abrasive Grade:

F8 F10 F12 F14 F16 F20 F24 F30 F36 F40 F46 F60 F80

F100 F120 F150 F180 F220

3. Applications :

A.The abrasive tools: grinding high carbon steel, high-speed steel and chilled steel.

B. Lapping and polishing medium

C. Crucible

D.Steel ladle

E. Catalyst carrier

F. Special ceramics and super refractory materials.

4. Physical Index:

Color | White |

True Density | 3.96g/cm3 |

Bulk Density | 1.75-1.95g/cm3 |

Microhardness | HV2200-2300 |

Mohs Hardness | 9.0 |

Melting Point | 2250°C |

5. Chemical Composition

Typical Value:

Al2O3 | 99.5% |

Na2O | 0.25% |

Fe2O3 | 0.04% |

SiO2 | 0.03% |

Abrasives Grade:

Grit Size | Al2O3 | Na2O |

F12-80 | >99.22% | <0.35% |

F100-240 | >99.0% | <0.4% |

Refractory Grade

Grit Size | Al2O3 | Na2O |

0-1mm | >99.22% | <0.35% |

1-3mm | >99.3% | <0.3% |

3-5mm | >99.3% | <0.3% |

200mesh | >99.0% | <0.4% |

325mesh | >99.0% | <0.4% |

- Q: what's the seal of fireproofing material?

- Organic fire-proof caulking is made by taking organic synthetic?resin as bond and compressing the components together after adding fireproofing agent, filler. The putty won't solidify after a long time usage and has good plasticity, can be sealed arbitrarily. This kind of putty is mainly applied in opening's fireproofing and sealing project of construction pipe and electric wire and cable, and it's used with ATD-AB and fire retardant bag together. ATD-AB is a kind of gray powder material, after mixed with water, it can be used for the opening sealing of electric wire and cable or fire resisting wall of wire tunnel. The fire proof blockage is non-toxic, and no smell, has good water resistance and oil resistance with simple construction methods. It's oxygen index is 100 and it belongs to incombustible?material. it's refractory time can reach 3 hours, or above or below. as for some projects for perpetual usage, WXY-II will save the project fee and make the project solid. A kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Fire retardant ring

- Q: What materials is silicious thermal insulation board made of?

- Refractories that contain more than 93% of the monox are acidic refractory materials which include ordinary silica brick, high-density and high-purity silica brick, silica brick that contains chromium, fused quartz products, unburned brick and siliceous ramming materials. It has good softening temperature under a fixed load and can resist corrosion of acid slag, but will have chemical reaction with alkaline slag. Silicious refractory of industrial value mainly is crystalline quartz, such as α and β quartz, tridymite and cristobalite.

- Q: What are the electrical fire protection materials?

- Flame retardant organic resin: They can be classied into PVC, vinyl chloride, chlorinated rubber, epoxy resin emulsion, epoxy resin, phenolic resin, etc.. Fire retardant additive: Phosphorus and halogens, nitrogen organic compounds (chlorinated paraffin, tributyl phosphate (TBP) and polybrominated diphenyl ethers) and boron (boric acid, zinc borate, boric acid aluminum), antimony, aluminum, zirconium inorganic compounds.

- Q: Does the production of refractory belong to advanced technology?

- It certainly is advanced technology as it is the new material.

- Q: What's the refractory material?

- Main components of basic refractory are magnesium oxide and calcium oxide, and magnesia brick is commonly used. For the magnesia brick with magnesium oxide content of more than 80%-85%, it has good resistance to basic slag and scum, and it has higher refractoriness than that of the clay brick and silica?brick. It is mainly applied to the open hearth furnace, oxygen-blown converter, electric furnace, non-ferrous metal smelting equipment and some high-temperature devices.

- Q: How to choose refractory material

- The crystalline refractory fiber mainly consists of polycrystalline mullite fiber, the optimum use temperature is 1300 DEG C, and the long-term use temperature of polycrystalline alumina fiber is 1400 DEG C. The service temperature of ordinary refractory fiber is 1150 degrees, and the use temperature of advanced refractory fibers (such as alumina, zirconia, refractory fiber) can reach 1700 degrees centigrade

- Q: What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named after its structure, especially referring to busway which is closely laminated between phases and between phase and shell and use thin insulating material to achieve the insulation result. Fire-resistant busway is named after its uses, just as its name implies, for higher fire safety requirements need busway of higher fire resistance level. The structural style of fire-resistant busway can be intensive and of air type, depending on what material it use to resist fire, so there is no direct link between them, but there is a included relationship.

- Q: What kinds of refractory materials that can resist 3,000 Celsius degree?

- I think that graphite is the only one.

- Q: Who knows about the B-level fireproof insulation materials?

- Commonly used B-level materials: Molding polystyrene foam, extruded polystyrene board, gelatine powder polyphenyl granule heat insulating slurry. Although the polyurethane is not the commonly used material, but the 9mm composite of monolayer gypsum board and PU insulating material can reach B-level.

Send your message to us

Raw Materials for Refractory:ISO Certified Low Na2O White Corundum/White Fused Alumina Grain with Al2O3 99.2 Min

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords