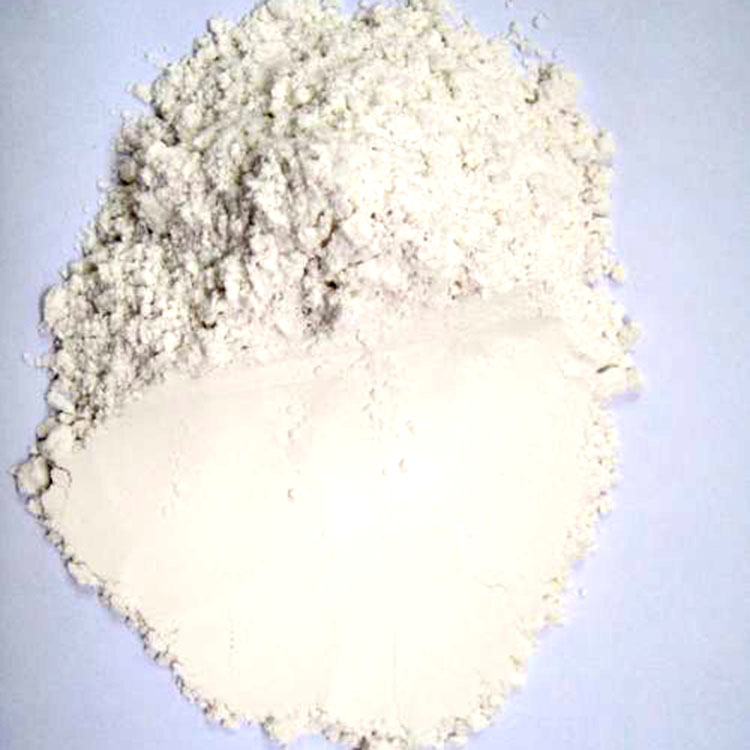

Raw Materials for Refractory - Fused Silica Powder 270mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q: Kinds of refractory mortar

- Refractory mortar can be divided into ordinary refractory material and special refractory material. Ordinary refractory materials can be divided into acidic, neutral and alkaline refractory materials chemical properties. Special refractory material can be divided into high temperature oxide, refractory compounds and high-temperature composite materials according to their components. Furthermore, according to refractoriness, it can be divided into general refractory products (1580 ~ 1770 ℃), high grade refractory products (1770 ~ 2000 ℃) and super refractory products (2000 ℃ above). It can be divided into bulks (standard bricks, special-shaped bricks, etc.), special shapes (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia filter and boron carbide , etc.) and indefinite shape (refractory clay, pouring materials and ramming mass, etc.). According to the sintering process, it is divided into sintered products, fused cast products and melting jetting products.

- Q: What the fireproofing materialare of the refractory kettle and where they can be sold?

- Many places sell these. Nearly 10 years, can't brun when it is dry, adsorption. You can also baidu these materials. Heat transfer evenly, feldspar, clay and other raw materials with a ceramic products. Traditional casserole can not resist heat difference and also can withstand for 100 high temperature without crack. Aiming at the problem of traditional casserole, easy to crack and air permeability, people joined the spodumene on raw material, produce a high-temperature resistance casserole. It is produced after the high temperature burning makes an earthenware pot to keep the original advantages. Hebei has many places to sell these materials and is also relatively cheaper. The traditional casserole has features of not easy to transfer heat's quartz and slow cooling. Due to production technology and raw materials, it greatly improves the casserole' practicability after research and improvement.

- Q: What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- While the refractory ceramic fiber cloth is different in high temperature resistance, and in general it can endure the high temperature of more than 1000℃. Ceramics in daily use and art ceramics: Bone china and Guangdong chinaware can generally endure the highest temperature of 1100℃. Jingdezhen porcelain and ceramics: They can generally endure the highest temperature of 1280℃-1340℃, and some special ones can endure the highest temperature of 1400℃. Industrial ceramics: Some of them can endure the highest temperature of about 2600℃. (alumina ceramics: their melting point is 2050℃, and boiling point is 3000℃).

- Q: What refractories are used in various parts of the blast furnace.

- Blast furnace from top to bottom has the throat, hearth staves, waist, bosh, hearth and furnace bottom. the specific structure is as follows: The throat is the first to be affected by the impact and abrasion, generally use high-density alumina bricks. the upper and central portion of temperature furnace is only 400 ~ 800 ℃, the area with high alumina bricks and silicate bricks. The lower part of furnace is subject to erosion and dust erosion alkali metal vapor due to high temperatures, it is required in such case to use high quality clay brick,high alumina brick,carborundum brick,corundum brick that is slag resistance and alkali?resistance, temperature resustant and wearproof. Furnace bosh temperature reached 1400 ~ 1600 ℃, serverly eroded by slag,vapor, flush. so we use carborundum brick and reaction-bonded silicon?carbide?brick. Bosh temperature reaching1600 ~ 1650 ℃, using alumina brick, corundum brick or silicon carbide brick. the temperature of Hearth near the upper portion of the outlet zone at 1700 ~ 2000 ℃, use of silicate bricks and corundum castable graphite filler, silicon carbide bricks. In 1450 Silly twitch bottom temperature sealing die of hunger slander bet phoenix astringent preserved Grade ~ 1500 ℃, use of graphite bricks and microporous carbon bricks, now use more corundum brick, corundum mullite brick and synthetic mullite brick. x26lt;P class x3d "share-btn"x26gt;

- Q: What kind of refractories do the anode baking furnace use?

- Use refractory bricks.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Why is the apple screen so small?

- Q: What are first rate fire resistant window materials?

- class A window not less than 1.2 hours, class B window not less than 0.9 hours, Class C window not less than 0.6 hours. technical requirments: 1, materials and accessories (1) the window frame is made with a certain strength sufficient to safeguard the integrity and stability of the steel frame or wooden frame. (2) steel frame and mound layer can choose the galvanized steel plate or stainless steel plate. Its selection standards is in line with GB12955 "Steel Fireproof Door General Technical Condition" provisions of Article 5.1. (3) wood frame and mound layer material selected from the standard should be consistent with GB14101 "General Technical Conditions of Wooden Fireproof Door" in the provisions of Article 5.1.1. (4 ) steel, wood frame the inside filler material should be incombustible material. (5) fireproofing glass can be used without affecting the fire windows fire resistance test approved product. light transmittance of glass should not less than 75% of commom sheet glass which is the same number of layers. ( 6) a sealing material between the frame and the fire-resistant glass flame retardant materials should be used, which can play the role of fireproofing and smoke insulation in case of fire (7) hardware fitting should be tested as approved supporting product

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q: What are the main materials in concrete fireproofing material?

- fireproofing materials mainly consist of class A incombustible?material and class B1 nonflammable material. Class A incombustible?material: Granite, marble, terrazzo, cement products, concrete products, gypsum board, lime products, clay products, glass, tiles, mosaics, steel, aluminum, copper alloy; class B1 nonflammable material: Ceiling materials, dry wall, fibrous plaster.

Send your message to us

Raw Materials for Refractory - Fused Silica Powder 270mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords