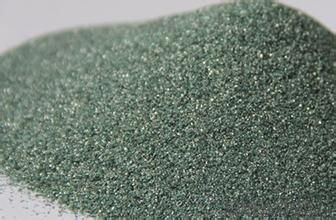

Raw Materials for Refractory:Factory Supply China Green/Black Silicon Carbide SiC F1500 Used for Abrasives and Polishing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon carbide

Products Description

With quartz sand and petroleum coke as its main raw materials, black silicon carbide is produced at high temperature in an electric resistant furnace. Its hardness is between corundum and synthetic diamond and its mechanical strength is higher than corundum, which makes it an ideal material for high quality abrasivetools.

Application

1. The most widely application of silicon carbide is producing abrasive tools, such as grinding wheels, cutting disks, etc. Black silicon carbide powder also could used as lapping and polishing media.

2. Black silicon carbide is suitable for processing glass, ceramics, stone, metal, rubber and other materials. 3. Black carborundum also can be used as metallurgical additive and high-grade SiC refractory material

Color | Black |

Basic Mineral | α-SiC |

True Density | 3.2g/cm3 |

Bulk Density | 1.45-1.56g/cm3 |

Mohs Hardness | 9.2 |

Microhardness | HV3100-3280 |

Chemical Composition of Black Carborundum

Typical Value

SiC | 98.60% |

Fe2O3 | 0.33% |

F. C | 0.16% |

Guarantee Value

Grit Size | SiC | F.C | Fe2O3 |

F12-90 | >98.7% | <0.2%< span=""> | <0.4%< span=""> |

F100-150 | >98.5% | <0.2%< span=""> | <0.4%< span=""> |

F180-220 | >98.0% | <0.3%< span=""> | <0.6%< span=""> |

F230-400 | >97.5% | <0.3%< span=""> | <0.6%< span=""> |

F500-800 | >97.0% | <0.4%< span=""> | <0.8%< span=""> |

F1000-1200 | >96.0% | <0.5%< span=""> | <0.8%< span=""> |

Size Available: Abrasives F16-F1200, P12-2500, JIS#240-JIS#3000 Refractory 0-1mm,1-3mm,3-5mm,200mesh,325mesh Other special specifications could be supplied as required.

We can also supply Green silicon carbide with different particle size F16-F1200 and other size etc.

- Q: What are the electrical fire protection materials?

- Flame retardant organic resin: They can be classied into PVC, vinyl chloride, chlorinated rubber, epoxy resin emulsion, epoxy resin, phenolic resin, etc.. Fire retardant additive: Phosphorus and halogens, nitrogen organic compounds (chlorinated paraffin, tributyl phosphate (TBP) and polybrominated diphenyl ethers) and boron (boric acid, zinc borate, boric acid aluminum), antimony, aluminum, zirconium inorganic compounds.

- Q: Is fireclay poisonous?

- Refractory materials are typically oxides, alumina, magnesium oxide and aluminate cement and etc, which are non-toxic.

- Q: How to use fireclay?

- Mix refractory cement (ie aluminate cement CA50) with some refractory aggregate (bauxite, slag from flint clay) and powder (ie, crushed aggregate). Add some water to the mixture and stir, and it can be used. The clinker can be refractory powder.

- Q: As for fireproofing material rock wool and glass wool, which one is better?

- As for fireproofing effect, the effect of rock wool is certainly better than glass wool , the highest temperature of rock wool is 1100 ℃, but the temperature of glass wool is only 600 ℃. In addition, if it's used in the external walls, then,unit weight of the glass wool is limited,and high unit weight can only be 60-90, but unit weight of rock wool can reach over 140, now external wall can't use glass wool, and only rock wool is A class fireproofing material. glass wool has lower thermal conductivity, rock wool has longer fiber length,as for the price, tons price of glass wool is more expensive than rock wool, but if it's acculated by square, square price of glass wool is cheaper than rock wool.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- The preparation of a report or statement. During the compilation process, any problems should be actively communicated with the construction side. For example, dust collector selection, environmental protection investment, total emission approval. (especially the total emission, you must let the construction side and communicate with the environmental protection bureau to get the total amount, otherwise you write the EIA does not make any sense.) Generally speaking, the preparation of the report is longer, about forty days; and the preparation of the report table is shorter, about fifteen days.

- Q: How much is the duration of fire resistance of the porous brick shale?

- This is really a simple question. The temperature should be limited within 1050℃, or it will be scorched. I think 980℃would be acceptable.

- Q: what is the fireproofing material of engine room? who knows it ?

- 1. The new type fire?retardant?coating in fire retardant coating, the expanded vermiculite, expanded perlite heat insulation material and cenosphere adiabatic powder, etc. These inorganic component, is a major part of the thick coating type of fireproof coating, and they also are the major factor affecting the level of performance of fireproof coatings. The fireproofing thermal insulation properties of fireproof coating, is mainly determined by the fire back surface temperature of this factor, but also related to the fire endurance. If it reaches the same temperature for a longer time, it shows that it's fireproof thermal insulation is better, and the fire endurance therefore is higher. 2. The new fireproof board new fireproof board now is welcomed by the people and the important factor is its environmental protection, and with the increasing high-rise buildings, the fire protection requirements and strength requirements are also rising, it is a big challenge for the performance and standard of the fireproof board.. Now fireproof board is mainly used siliceous material or calcareous materials, and then mixed with the fiber material, lightweight aggregate, adhesives and chemical additives, it is not only be fireproofing, but also improve their thermal insulation performance, and light weight, good carrying capacity, good durability, no aging problem, more importantly, it is good in environmental protection.

- Q: Does anyone know what is a lightweight refractory material?

- Light weighted castable is one of the kind.

- Q: What are the types of steel refractory materials

- Large steel ladle usually made with magnesia carbon brick, of course, it contains a intermediate layer (such as good a little high alumina castable), heat insulation layer and heat preservative materials Alumina-magnesia castable is OK for small steel ladle

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- Could you tell me the fire-resisting time of class B fire proof door?

Send your message to us

Raw Materials for Refractory:Factory Supply China Green/Black Silicon Carbide SiC F1500 Used for Abrasives and Polishing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords