Raw Materials for Refractory:Black Silicon Carbide for Abrasives and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | silicon carbide | Model Number: | silicon carbideF4-f240 |

| Material: | silicon carbide | Usage: | abrasive for grinding ball,refractory material, | Abrasive Grain Sizes: | F4-F240 |

| silicon carbide: | black |

Packaging & Delivery

| Packaging Details: | 25 kg bags on pallet up to 1 ton 1 ton loose in big bag |

| Delivery Detail: | 15days |

Product Description

Products Picture

Black silicon carbide consists of crystalline silicon carbide, which is produced from silica sand and petroleum coke in electric resistance furnaces at temperatures of > 2.300 °C. Silicon carbide is iron-free, angular and extremely hard.

Applications:

Reusable abrasive

Grinding, lapping and polishing medium

Grinding wheels and grinding medium

Wear-resistant and refractory products

Blasting systems:

Pressure blast systems

Injection blast cabinets

Speciafication

| Typical physical properties | |

| Hardness | approx. 9 - 10 mohs |

| Grain shape | angular |

| Melting point | approx. 2300 °C |

| Specific gravity | approx. 3,2 g/cm3 |

| Bulk density (depending on granular size) | approx. 1,3 – 1,5 g/cm3 |

| Typical chemical analysis | |

| SIC | 98,00 % |

| Fe2O3 | 0,24 % |

| C-frei | 0,50 % |

| Magnetic particles | 0,12 % |

| Available sizes | |||

| FEPA | Average grain size | ||

| ds3-Factor max. μm | ds50-Factor μm | ds94-Factor min. μm | |

| F 230 | 82,0 | 53,0 +/– 3,0 | 34,0 |

| F 240 | 70,0 | 44,5 +/– 2,0 | 28,0 |

| F 280 | 59,0 | 36,5 +/– 1,5 | 22,0 |

| F 320 | 49,0 | 29,2 +/– 1,5 | 16,5 |

| F 360 | 40,0 | 22,8 +/– 1,5 | 12,0 |

| F 400 | 32,0 | 17,3 +/– 1,0 | 8,0 |

| F 500 | 25,0 | 12,8 +/– 1,0 | 5,0 |

| F 600 | 19,0 | 9,3 +/– 1,0 | 3,0 |

| F 800 | 14,0 | 6,5 +/– 1,0 | 2,0 |

| F 1000 | 10,0 | 4,5 +/– 0,8 | 1,0 |

| F 1200 | 7,0 | 3,0 +/– 0,5 | 1,0* |

| * at 80% | |||

Other grain sizes can be produced if required. | |||

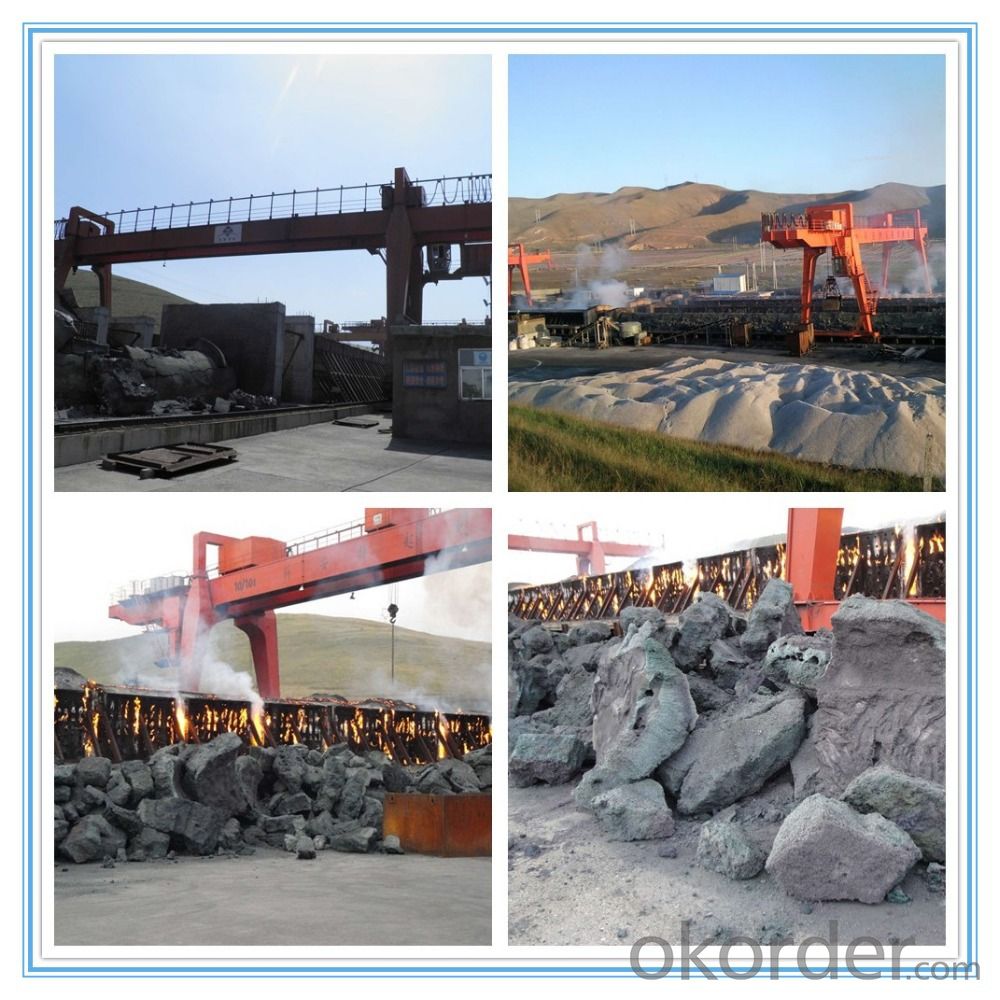

Factory and Package

Metallurgical Refinery

Grain Factory

Package

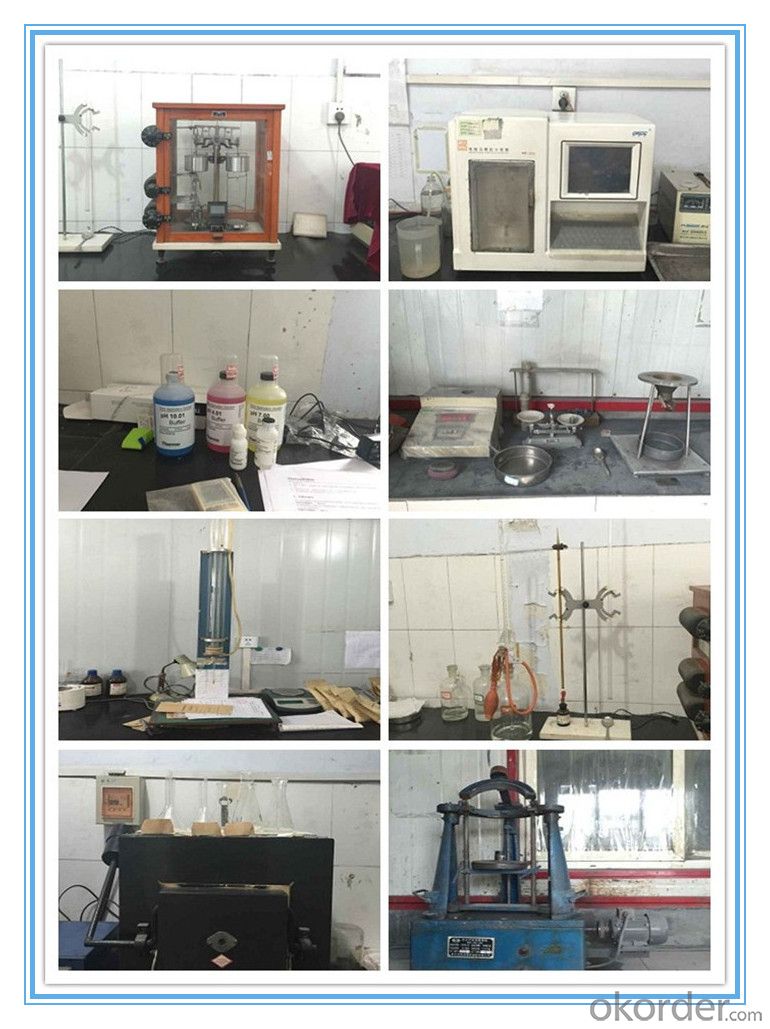

Equipment

FAQ

1 Your production capacity?

A: 3000 ton every month.

2 Will the free sample be provided for us?

A:We will provide free sample about 1 kg.

3 Did you have your own mancfactory?

A:Yes,We have.

- Q: What are unshaped fire-resisitance materials?

- Refractory castable, refractory plastic material, usually classified according to construction and manufacture method, unfired bricks precast block, refractory pressed into material, refractory cast material, refractory coating, refractory ramming material there are many classification methods

- Q: Which brand of thermal insulating refractory is good?

- Brands of thermal insulating refractory: 1, Armaflex(German brand). Manufacturer: Armacell thermal insulation materials (Guangzhou) Co., Ltd, Armacell thermal insulation materials (Suzhou) Co., Ltd. 2, Durkflex (American brand) Manufacturer: Durkee (Guangzhou) thermal?insulation?material Co., Ltd. Durkee (Wuhan) thermal?insulation?material Co., Ltd. 3, Aeroflex (Thailand Brand) Manufacturer: Aeroflex Polymer Technology (Shanghai) Co., Ltd.

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- Physical and chemical property indexes of high strength and high alumina refractory bricksProject indexPLG-1.0 PLG-0.8 PLG-0.5 PLG-0.4AI2O3% 56545250Fe2O3%, 2, 2, 1.5, 1.5Bulk density g/cm3 1, 0.8, 0.5, 0.4Normal temperature compressive strength MPa shall be no less than 7531.5A change of a burn line of not greater than 2%The temperature is 1400140012501250 centigradeThe coefficient of thermal conductivity, W/m.k average temperature (350 + 5) is not greater than 0.45, 0.35, 0.25, 0.20

- Q: About the market issues of thermal insulation material and refractory material.

- After all, most people have the characteristics of being accustomed with something and it will not change easily ; second, the South has few material manufacturer, but in the Northeast, there are thermal insulating and refractory material manufacturers, which is in shortage, however, but irt is in the minority, and in many areas it is not suitable for exploitation of mineral (due to heavy industry and agriculture land and other reasons). I hope that my answer will help you. first, in the Northeast, the refractory material is not very rich, but the thermal insulating and refractory material demand is very large; third; fourth, which material is used more relived, after all, we should take the transportation costs into account, and it will depend on the kilns construction engineers being willing to use which kind of material, and the thermal insulation material procurement in northeastern region is mostly from the north.

- Q: Which industry does refractory belong to?

- It belongs to inorganic refractory: Ceramic refractory bricks (used in steel-making furnaces) There is also organic polymer in heavy industry: Halogen-containing and halogen-free It belongs to construction industry.

- Q: How to choose refractory material

- Refractory fiber in different furnace material requirements are different, I would like to know is methanol as a protective gas, fire fiber, cotton material what?.

- Q: How many kilns using refractories are needed? What are the furnaces respectively?

- Kiln and five hundred-degree centigrade thermal equipment need to use refractories, glass furnaces, electric arc furnaces, mixer, cement rotary kiln, open hearth furnace and limestone kiln; in fact, when the temperature is more than four, the mesh belt furnace, blast furnace, cupola oven, stove, pushing plate kiln, furnace, heat treatment furnace, roller kiln, down draft kiln, ladle, coke, shuttle kiln,etc.

- Q: What types does refractory floor include?

- There are many types refractory bricks, including silicon aluminum refractory brick, the leading product in refractory bricks. And its high temperature resistance can reach up to 600 degree centigrade or more, so it is an excellent refractory brick. And this high-alumina refractory brick is very suitable for metal industry for its strong practicability. Another one is alkaline series refractory brick, including magnesite refractory brick, and these two bricks are good materials resistant to high temperature.

- Q: How long is the fire endurance of fire resistant rolling shutter door?

- According to the new national standards GB_12955-2008 for fire doors from January 1, 2009, fire doors are classified acoording to thermal insulation fireproof door(A),part heat insulation fireproof door(B) and non thermal insulation fireproof door(C), rather than thermal insulation fireproof door. At the same time, the original fire endurances of class A, B and C fire doors are adjusted to 1.5h, 1.0h and 0.5h respectively. So, GB is 1.5h

- Q: How to divide fire resistant level of fire door?

- Fire resistant level of fire door【Class A fire door】. Class A fire door is also called complete fire door. It can meet the requirement of fireproof thermal insulation and refractory integrity at the same time in specified time. Fire resistant levels are 0.5h(Grade C), 1.0h(Grade B), 1.5h(Grade A) and 2.0h, 3.0h. 【Class B fire door】Class B fire door is also called part heat insulation fireproof door. Its requirement of fireproof and thermal insulation performance is 0.5h. Refractory integrity levels are 1.0h, 1.5h, 2.0h and 3.0h respectively. 【Class C fire door】Class C fire door is also called not thermal insulation fireproof door. Ther is no requirement of its fire resistance and thermal insulation. It only meets the requirement of refractory integrity in specified refractory time. The grading of refractory integrity is 1.0h, 1.5h, 2.0h and 3.0h respectively. There is the content of not thermal insulation fire door in British BS standard.

Send your message to us

Raw Materials for Refractory:Black Silicon Carbide for Abrasives and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords