Raw Materials for Refractory:Alumina Aluminum Oxide Al2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Use Alumina Aluminum Oxide AL2O3

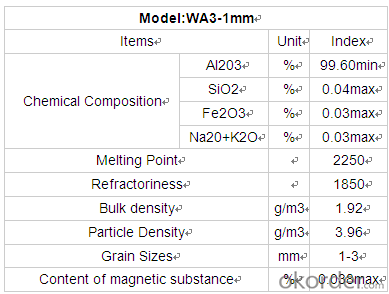

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application:

1- Used as refractory material in electronic, metallurgical,textile and oxidizing industry.

2- castable refractory product for brick,wall, plate or cover.

3- Suitable for atmospheric temperature recovering equipment.

4- A fluorine removal agent of drinking water.

5- temperature resistance above 1700 degree.

5. at high temerature, transform into alpha alumina.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: Who knows what is the external wall thermal insulation materials for level A fireproofing?

- In general, external wall thermal insulation materials can be divided into level A and level B by combustion grading. Level A is non-combustible material, and level B is combustible materials. A few years ago, the fire of the CCTV Building and Shenyang Hotel put the blame on the level B material. At present, the level A material is widely used, and the prices of same level A materials may be even cheaper than the level B material. Level A material is generally divided into thermal?mortar, phenolic foam board, rock wool board and foam cement board. I hope this information can be helpful to you. Hope you adopt.

- Q: What are the requirements of refractory temperature of refractory brick?

- Oxygen fluctuation of load once happened during operation. Sometimes oxygen control valve will cause oxygen fluctuation of load, and sometimes large particles will block valve of high pressure coal slurry pump. The sudden drop in flow of coal slurry may cause relative excess of oxygen. Oxygen fluctuations directly cause fluctuations in furnace temperature. The range of oxygen fluctuations is 500m?-600m?. The maximum can reach about 1000m?. A sudden increase in oxygen causes a sudden increase in furnace temperature, which will suddenly burn out high-temperature thermocouple. The situation has a great influence on refractory brick and should be avoided. Furnace temperature is very inportant to life of lining of refractory bricks, so it should be strictly controlled not to overheat. There is a cinder layer on the surface of refractory bricks under the condition of normal production. In fact, cinder layer is dynamic. If the temperature is low, cinder layer is thick. If the temperature is high, cinder layer is thin. Appropriate cinder layer may slow the scour of high temperature gas and molten slag. The requirement of refractory brick is higher than that of stoves which use heavy oil as raw material. The main reason is permeability and corrosion of molten slag to refractory material. When replacing refractory bricks, it is found that penetration thickness is 10mm-20mm. After slag penetrates, strength decreases significantly. If temperature is high, erosion intensifies. According to the relevant information, when the operating temperature exceeds 1400 ℃, etching effect multiplies.

- Q: How to apply the alumina powder on refractories?

- What kind of the refractories can make the aluminium oxide increase the aluminum content and specific gravity, and erosion-resistant.

- Q: Does anyone know about the classification standards of B2-level fireproof and thermal insulation materials?

- The fire-resistant differences of B1- and B2-level extruded insulation boards are as follow: B1-level materials will be smothered as soon as staying away from fire, namely, they will be extinguished after leaving fire, or be put out in 10 seconds. B2-level materials will be in low-grade combustion, namely, the fire will not get wilder, and drippings will not ignite the filter paper. I hope my answer can help you!

- Q: Is the linear change on reheating the same as heating permanent linear change of refractory material?

- “+”represents expansion. the afterexpansion and aftercontraction after cooled to be at room temperature. The change may significantly damage the masonry of thermal kiln. There are regulations on the linear change on reheating of common refractory material in the national standard. Some physical chemical changes may continue. It is defined as the change from being heated to the specified temperature of refractory material sample. Heat preserving for a while till afte cooling to be at room temperature, then the residual will expand or contract in its length, heat preservation for a while, organization vitrification, the irreversible changes of its length refers to heating the firing refractory to be at high temperature, so as to make the volume of refractory materials expand or contract, due to the influence of uneven temperature or lack of time, otherwise it will cause the deformation of the refractory ball and make this indicator within standard even reach smaller value, so firing control must be strengthened in product production. But it is should not be too high. For refractory materials with same chemical composition, the linear change on reheating is produced in the heating process. Properly increasing sintering temperature and prolonging the holding time is an effective process measures, make its firing inadequate. When subjected to high temperature, it can reduce the thermal shock resistance. Minus sign "-" represents contraction. The permanent line rate refers to heating the fire refractory ball to the specified temperature. Linear change on reheating, also known as residual linear change, is an important indicator to assess the quality of refractory in the long time use. To control the permanent line rate within the standard or reach the minimum value.

- Q: Manganese steel belongs to refractories

- NO!

- Q: What does refractory mean?

- Ordinary refractories are often used brick, semisilica brick, clay brick, high alumina brick, magnesia brick etc..Special materials often use AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so onUnshaped refractory materials commonly used are fettling, refractory ramming material, refractory castable, refractory plastic material, refractory clay, refractory gunning, refractory cast material, fireproof coating, lightweight castable, mud etc..

- Q: What material is used for making refractory stone bowl?

- It is attractive and diverse in appearance, hard, and heat fast, not stick food when using. The cooked food is attractive and delicious and rich in various trace elements which is beneficial to the human body. It is also of high quality, and all these make it popular among the customers.

- Q: Introduction to refractory material

- The best way to learn is on-site contact. If for produing purpose, it is better to ask teh leader of a plant. If for application, go to steel mill (cement plant, glassworks, etc.) to learn and look up information. Theory alone is of no help.

- Q: What refractory materials are used in power plant

- And then I will introduce some application of thermal material in power plant (below) I hope I can help you. Energy saving is the trend of future industrial development efforts, grinding machine, conveyor belt, so the production of light thermal insulation materials will gain state support, drying kiln. Our factory mainly produce light thermal insulation brick. The refractory material we use most is light insulation brick, and the equipment used is sand mixer (Luohe, Henan)

Send your message to us

Raw Materials for Refractory:Alumina Aluminum Oxide Al2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords