Alumina Oxide Al2O3 - Raw Materials for Refractory - Industrial Grade Good Quality Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial grade Good quality alumina oxide al2o3

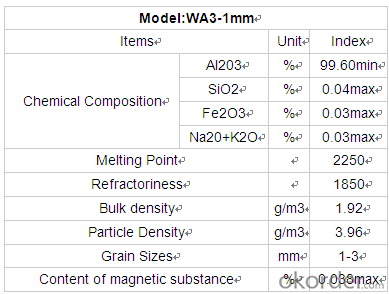

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application of AL2O3

Aluminum Oxide for aluminum smelting, glass, ceramic industry etc.

Aluminum Oxide for refractory, coating, abrasive application.

Aluminum Oxide for electric basal plate, desiccating agent, chemical and pharmacy industry etc.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: Who knows how many fire heat preservation material are there?

- They can be divided into wood fire, steel fire and stainless steel fire. Wooden fireproofing material is light weight, easy for installation and second decoration, as well as all types of civil construction and some industrial buildings. It can be realized through inorganic insulation materials, such as glass wool, rock wool, foam glass etc.. The phenolic foam materials inside organic foam material is more special. Phenolic foam does not only have a good thermal insulation performance, but also can be combined with steel and other materials, to achieve a class A fire retardant level. Class A thermal insulation include: 1 thermal insulation materials with class A combustion performance Fire insulation materials of fire barrier zone can use class A material with class A combustion performance in rock (ore) cotton, foam glass, inorganic thermal insulation mortar.

- Q: Can someone professionally introduce the classifications of refractories?

- Whatare the classifications of the refractory index levels? There are three categories of refractory index levels. Anyone familiar with the industry may already know that if you're new to the refractory and don't know much about it, the following information may be helpful to you. Refractory index level can be devided into three general categories of special refractories, advanced refractories and ordinary refractories. The first category, special refractories. Whose refractoriness is higher than 2000 ℃, spinel brick, pure oxide products, high purity directly bonded magnesia-chrome brick, cast products, non-oxide products belong to this grade. The second category, advanced refractories. Whose refractoriness is from 1770 to 2000 Celsius degrees, mullite bricks, high alumina brick, magnesia-alumina brick, ordinary magnesia products, olivine bricks, ordinary magnesia-chrome brick belong to this grade. The third category, ordinary refractories. Whose refractoriness is between 1580 and 1770 Celsius degrees, equivalent to Al2O315% ~ 45% refractory products in the binary system of SiO2-Al2O3. Kaolinite is the main mineral of raw materials.

- Q: What's the maximum temperature that the high-temperature resistant refractory ceramic fiber cotton can endure?

- It depends on what material the ceramic fiber gasket uses. It’s usually referred to high temperature gasket made from ceramic fiber paper. It is generally classified into normalized form and high alumina type, of which the former can resist the maximum temperature of 1260℃ and its continuous use temperature is 1000℃, and the latter can be used for a long period at the temperature of 1200℃. Nichrome wire, stainless steel wire and glass fiber are reinforced. Ceramic fiber coating cloth and slag cloth, sintering ceramic fiber cloth and ceramic fiber fumigation cloth) Characteristics of the ceramic fiber cloth: It has high temperature resistance, low heat conductivity, thermal shock resistance, low thermal capacity; superior insulating property at high temperature, long service life; resistance to nonferrous metals like molten aluminum and zinc erosion; low and high temperature strength; innocuity with no adverse effect on the environment.

- Q: How about the prospect of refractory material?

- Due to the rise of raw material, the prospect is not good with inflation, lower prices and decreased profits. The product requirements have been enhanced and there is vicious competition. Therefore, it is really bad.

- Q: How can refractory material of the electric furnace be used for longer.

- Minimize mechanical shock, Electrical furnace commonly referred to must be electrical arc furance. The wall of electric arc furnace should be constrcuted with magnesite carbon brick. Its hearth permanent layer should be constrcuted with mansornary magnesia brick. High alumina brick is usually used to aviod furnace cover suddenly get hot and cold. But its service life is lower. At present integral casting furnace cover is made of alumina magnesia. Terminal will be created even without the use of refractory material. Consumption is much faster if using refractories material or whole knottiing mainly.

- Q: What antioxidant will be used in refractories?

- Specifically speaking, it is an antioxidant used in carbon refractory products, which belongs to the fire resistant technology. A kind of refractory used antioxidants, formula proportion is as follows calculated by weight percentage: aluminium zinc alloy 1 ~ 100, conventional antioxidants in 0 ~ 100. Described in the aluminum zinc alloy element of aluminum content is 3% ~ 3%, the rest is zinc. Described aluminium zinc alloy is powder or fibrous long; The biggest size and long fiber powder makeup of maximum diameter is 0.2 mm. Preparation of the present invention contains aluminum zinc alloy antioxidants can prevent carbon oxidation temperature range is big, less side effects, and can adjust the thermal expansion of refractory. Hope I can help you.

- Q: What are the chemical composition of refractory cement?

- Calcium aluminate prepared by calcining as the main component. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement.

- Q: what is the fireproofing material of engine room? who knows it ?

- machine room fireproofing materials include: Inorganic binder: The main material includes sodium silicate, gypsum, phosphates, cement,ect.; refractory mineral filler: aluminium oxide, asbestos powder, calcium carbonate, perlite, cornstarch, ect.; nonflammable organic resin: it mainly includes polyvinyl chloride, perchloro-ethylene, chlorinated rubber, neoprene latex, epoxy resin, phenol resin, ect.. nonflammable fireproof addictive: it mainly has phosphorus, halogens, nitrogen organic compounds (chlorinated paraffins, tributyl phosphate,deca-brominated diphenyl ether), and boron series (boric acid, zinc borate, aluminium borate), antimony system, aluminium series, zirconium system, etc. inorganic compounds.

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named according to its structure, and fire-resistant busway is named after its uses. Compact busway especially refers to busway which is closely laminated between phases and between phase and shell, and use thin insulating material to achieve the insulation result. suitable for power supply system of alternating current three-phase four-wire, three-phase five-wire system, frequency of 50 ~ 60Hz, rated voltage up to 690V, rated operational current of 250 ~ 5000A, as auxiliary equipment for mining, enterprises and high-rise buildings, and especially suitable for the transformation of workshop and old enterprises. Fire-resistant busway is composed of shell coated with fire retardant paint, bus line wrapped with fire-resistant mica tape and bracket made by refractory insulating material. Bracket has a plurality of grooves where inbedding the bus line and fixed it. There is a busway connecting box at one end of the busway and there is a bus line splitter box in the busway. Fire-resistant busway has excellent insulation properties, which can not only be used continuously in a normal environment, but also can be used in the fire environment continuously for more than one hour, suitable for high-rise buildings and important facilities, replacing the fire-resistant cables to transmit and distribute power .

- Q: which kind of refractory is commonly used in the industry

- Like silicon, magnesium calcium and metallurgy refractories, glass, silicon, etc., knowing the basic materials, and the businesses are not the same. I suggest that you can buy the refractory book to read.. Others include zircon, shapeless refractory material and so many other cement, such as magnesia, high alumina,ect.. Iron making is using the acidity material, continuous casting is using the clay, nonferrous metals and other types of more complex hot-press charcoal; steel making is using the alkaline, magnesium chrome, magnesium carbon, and clay,etc..

Send your message to us

Alumina Oxide Al2O3 - Raw Materials for Refractory - Industrial Grade Good Quality Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords