Raw Materials for Refractory:98.5 Silicon Carbide90/Recrystallized Silicon Carbide/SiC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

98.5 Silicon Carbide90/Recrystallized Silicon Carbide/SIC

1.Structure of Silicon Carbide Description

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

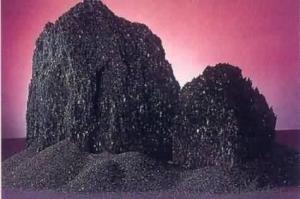

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

Items | Unit | Index | Typical | ||

Chemical composition | SiC | % | 97.00min | 98.5 | |

F C | % | 0.30max | 0.17 | ||

Fe2O3 | % | 0.4max | 0.3 | ||

SiO2 | % | 1.50max | 0.21 | ||

MI | % | 0.03max | |||

| Refractory grade | Grain | mm | 0-50,0-1, 1-3, 3-5,5-8 | ||

| Fines | mesh | -200, 325 | |||

| GritF grade and P grade | FEPA | 16, 24, 46, 100,180,220 | |||

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: What are included in wall fireproofing material?

- External wall thermal insulation materials are divided into A and B according to combustion level. Grade A is incombustible material, while grade B is combustible material. A few years ago, fires in CCTV building and Shenyang hotel resulted from grade B material. Currently grade A is usually used, and some are even cheaper than the grade B material. Grade A is roughly divided into insulation mortar, phenolic board, rock wool board, foam cement board, etc. Insulation mortar is quite good. It is easy and convenient to construct, has low cost, but the production is too simple and it is easy to fake.

- Q: How to solve the shell, the crack problem of refractory material in the process of forming.

- Pressure mode and number of pressure control "spallation". 2, multiple pressure, pressure degree and discharge way: 1, reduce friction, choose appropriate, than big pressure disposable pressure produced by the plastic deformation, allocate reasonable grading, internal and external friction, reduce billet particles and high die wall bright. 4.--- solve the light one firstly. --moisture content being too high easily cause spallation - the compressibility of water is small and have certain elasticity, appropriately to extend the pressuring time is beneficial. The material can produce large plastic deformation under the effect of continuous load. The right amount of lubricant. - body under the condition of less pressure but long effect time molding. Mould structure is reasonable and improve billet natural stacking density. 5.3, measures to improve the unburned brick molding quality. Many times continuously pressure relief is better than one-off sudden unloading, and controlling the appropriate moisture content;- - is beneficial to air overflow.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- 1. after roasting at high temperature of more than 1200 degrees, shale burned bricks in construction works can be free from expanding with heat and contracting with cold. 2. masonry walls can be plastered with no needs of any anti-cracking, reinforcement measures, and walls will not bulge and crack, which can reduce the construction cost, as well as are preferred building materials of frame structural engineering. 3.They have good sound insulation and thermal insulation performances, are one of the green building materials that the state currently promotes. 4. They have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance.

- Q: How to choose thermal insulation materials for flood heating?

- 1, Select the appropriate floor material suitable for radiant floor heating. The floor radiant heating system mainly transfer heat through the ground concrete and the ground material to the room. Therefore in the heating season the ground material will always be heated during heating season. Therefore, it is better to choose stone materials and compround floor plate insensitive to tenmperature change with good heat dissipation and functions. Currently, wood floor is not suitable for the ground radiant heating system. 2, choose the pipe with anti permeability performance. Plastic floor heating pipe itself has a certain air permeability, if oxygen penetrates in it is prone to oxygen erosion and system's mental device will be eroded, resulting in the risk of leakage. Therefore in order to ensure the reliable operation of the heating system, the selected pipe must have anti oxygen permeation performance, and meet the standard stipulated by the DIN4726 oxygen permeation quantity: and be less than 0.1mg\L.d at 40 C.

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q: Please answer the questions about the packing and transportation requirements of refractory materials.. Requirements for packing of refractory bricks

- Exports should be fumigated outside of South East asia. Pallet packing is the most common, convenient and inexpensive.

- Q: Does anyone know which materials belong to light fire resistant material?

- Fire partitions can be divided into organic and inorganic fire partitions, the main ingredient of organic fire partitions is organic material, which can be used for cable tray with corrosion-resistant and fire protection requirements, and the main ingredient of inorganic fire partitions is inorganic material, mainly used for fire protection. As the main component is inorganic material, it can not be use in projects with acid-resistant and alkali-resistant requirements. Of course, the price of the same amount of organic fire partitions is generally more expensive than that of the inorganic fire partitions . The fire endurance of these two products of general enterprises are 3 hours.

- Q: Which kind of external wall fire barrier zone material is better?

- The following types are: rock wool, aerated concrete, phenolic aldehyde and foam cement rock wool fire barrier zone "rock wool board" mainly uses water-repelling rock wool board produced by pendulum method as thermal insulation layer materia, and connecting and fixing base wall by binding and nail bonding, it is composed level A non-combustible building energy efficiency thermal insulation system by plastering layer composed by plastering mortar and glass?fiber mesh and decorative mortar finishing layer or coating. Good air permeability

- Q: What kind of foundry ingot refractory materials are there? Please be more detailed.

- This question is a little bit extensive, because there are too much foundry ingot refractory materials.

- Q: What thickness is needed of the ultra-thin fireproof paint with a fireproof time of 2.5 hours?

- The thickness of steel structure fire retardant coating hasn't been regulated in the steel structure application specification (CECS24:90). The above thickness refers to a certain thickness that must (at least) achieve a certain time of the fire resistance. The thickness of fire-retardant coating in engineering is generally determined according to factory inspection report. We use thin steel structure fire retardant coating: 2.5 hours' fire resistance with the thickness of 4.9 mm; 2.0 hours' fire resistance with the thickness of 3.5 mm; 1.5 hours' fire resistance with the thickness of 1.75 mm; 1.0 hours' fire resistance with thickness of 1.17 mm. I hope I can help you.

Send your message to us

Raw Materials for Refractory:98.5 Silicon Carbide90/Recrystallized Silicon Carbide/SiC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords