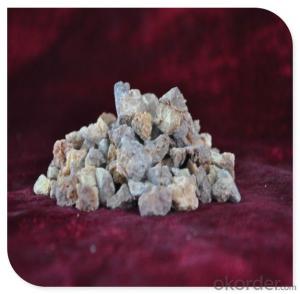

Raw Materials for Refractory:90% MgO Dead Burnt Magnesite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory 90percent MgO Dead Burnt Magnesite Price

Dead Burned Magnesite

Description

Dead Burnt Magnesite is produced in the Rotary Kiln by sintering raw magnesite at a controlled temperature of 1750 degree centigrade and its chemically inactive. Dead Burnt Magnesite is consume almost exclusively in the production of Refractory Field.

Dead Burnt Magnesia Application:

1. Refractory Industry for manufacture of Basic Refractory Bricks .

2. Manufacture of Ramming Mass composition, Fettling material and Magnesite Mortar.

3. It is used in SLAG beneficialness and in SLAG splashing in Arc Furnaces.

4. It is also used as a coating material in Steel Industry.

MgO ≥ | CaO ≤ | SiO2 ≤ | L.O.I. ≤ | BD ≥ g/cm3 | size mm | |

VT-MGO-DBM 87 | 87 | 2.2 | 7.0 | 0.5 | 3.1 | according to the requirement of customer |

VT-MGO-DBM 90 | 90 | 2.2 | 5.0 | 0.3 | 3.15 | |

VT-MGO-DBM 91 | 91 | 2.0 | 4.5 | 0.3 | 3.18 | |

VT-MGO-DBM 92 | 92 | 1.8 | 4.0 | 0.3 | 3.18 | |

VT-MGO-DBM 93 | 93 | 1.6 | 3.5 | 0.3 | 3.18 |

Our Lab

Our service

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is used to thermal insulation and the transfer of heat insulation. refractory material is defined as greater than 1580 ° non-metallic materials, such as calcium silicate board. its using temperature can reach to 1100 degrees, and some can also be used at high temperatures, and all high-temperature industrial can't be oprated without it, and the using temperature of polycrystalline alumina fibers can reach to 1800 degrees

- Q: About the market issues of thermal insulation material and refractory material.

- After all, most people have the characteristics of being accustomed with something and it will not change easily ; second, the South has few material manufacturer, but in the Northeast, there are thermal insulating and refractory material manufacturers, which is in shortage, however, but irt is in the minority, and in many areas it is not suitable for exploitation of mineral (due to heavy industry and agriculture land and other reasons). I hope that my answer will help you. first, in the Northeast, the refractory material is not very rich, but the thermal insulating and refractory material demand is very large; third; fourth, which material is used more relived, after all, we should take the transportation costs into account, and it will depend on the kilns construction engineers being willing to use which kind of material, and the thermal insulation material procurement in northeastern region is mostly from the north.

- Q: Who knows the external wall thermal insulation materials fire rating requirements?

- The basic requirements of ratings. The design should comply with relevant state regulations and standards, the combustion performance used in exterior insulation material shouls be level A and not less than the level B2 fireproofing material. The requirements of Department of Housing and the Ministry of Public Security No. 46: Residential buildings: the height of building is greater than 100 meters, the combustion performance of insulation materials should be level A. The other civil buildings: 24≤ height

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- If the outer packing is made of solid wood, it must be fumigated! If it is not solid wood, you can do without!

- Q: What are the types of refractory sealant?

- Hello: I'm glad to help answer your questions! Measure fireproof material is high polymer plastic seal material which is used for seal. It has a dual performance of both sealing and fireproofing. It can be applied for fire protection construction of metal pipes, thermal insulated pipes and construction juncture. Fire-resisting sealant has an expansion rate of greater than 20% and it is resistant to nuclear radiation, LOCA, detergents, and it has radioactive decontamination performance. It has a durability of more than 40 years; It is free of halogen, sulfur and other toxic matters, watertight, anti-smoke, corrosion free, safe and environmental-friendly. It gives off no toxic smoke and is efficient in inflamming retardancy which is easy to construct. I hope my answer will be helpful to you.

- Q: What are the main characteristics of the sic refractories?

- 1. The usge temperature of silicon carbide refractory is generally 1760 ℃ 2. The silicon carbide refractories can withstand the dramatic changes of temperature and have a good thermal shock resistance performance. To prevent the cracking or breaking of lining refractories. 3. Under the conditions of high or low temperature, it can withstand a certain compressive stress. 4. Under the conditions of high or low temperature, it can withstand friction. 5. It can withstand the huge hydraulic pressure or buoyancy of the metal. 6. It can also withstand the effect of furnace gases to prevent the infiltration of other refractories and reactions.

- Q: what's the detailed address of fireproof and thermal inuslation matertial market?

- following are the detailed address of fireproof and thermal inuslation matertial market: Central China Building decoration materials market,Hanxi 1 road No 95, Xinyongan Tangcai decoration material makert, Jianghan district Tangcai road No 53, Baoye decoration material wholesale market, Wuhan Wuchang district Minzhu road No 620.

- Q: how long is the fire endurance of plasterboard?

- Gypsum board is flame retardant materials, combustion performance rating B1, but when mounted on a steel joist, it can be seen as rating A(non-combustible material) . So it is fine to use as a ceiling. You can randomly choose several samples to run some tests at the quality inspection insititute and the quality of these samples are subject to the testing results.

- Q: How to divide fire resistant level of fire door?

- The classification of fire resistant level of fire door: Grade A is not less than 1.2h. Grade B is not less than 0.9h. Grade C is not less than 0.6h. It is suitable for fire door with different levels: Grade A: Equipment room (such as fire-pump room,power distribution room, generator room, smoke control fan room, etc) door, fire?compartment, door on firewall; Grade B: Eclosed staircase, front door of stair room, smoke-proof?staircase and fire elevator share lobby door, front door of fire elevator, household door which directly opens to front room or shares room; Grade C: The vertical shaft door, such as strong electric wells, weak electric wells, pipe shaft door and air conditioning facilities. I hope this information can help you.

Send your message to us

Raw Materials for Refractory:90% MgO Dead Burnt Magnesite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords