RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 28000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

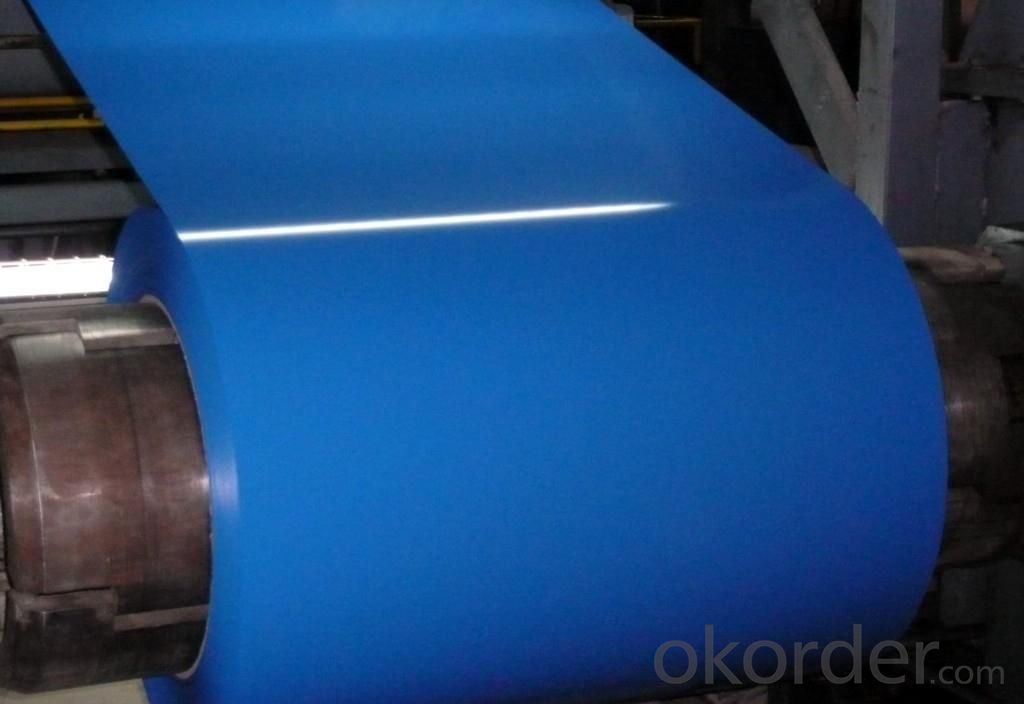

Structure of RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

Description of RAL Scale Z65 Prepainted Rolled Steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing PPGI is featured with light- good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation.It is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

Specifications of RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

Specifications of RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

Product | RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each color. And we could give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your can offer the better price we can provide.

2. How long can we receive the product after purchasing?

Usually within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15- 25 days, but the shipment will depend on the vessel situation.

3. What is your package of the products?

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

- Q: What are the common applications of hot-dip galvanized steel coils?

- Hot-dip galvanized steel coils have a wide range of common applications, including roofing and construction materials, automotive parts, electrical appliances, and agricultural equipment. The galvanization process provides excellent corrosion resistance, making these coils ideal for outdoor structures and applications exposed to harsh environments.

- Q: I am a beginner (never played before!) and I am going to try to teach myself since I think it is a lovely instrument. I am fourteen-years-old so I am not 'adult-size', haha. Anyway, what is difference between nylon strings and steel strings?Thanks :)

- Small guitars easier to find in classical range. I assume their must be small steel strings but not seen them.

- Q: What we have to keep in mind before buying a steel building?

- Before okorder /... Hope this will prove helpful to you.

- Q: How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials by being fed into a roll-forming machine, which shapes the coils into the desired profile for the roofing panel. The coils are then cut to the appropriate length, coated with protective finishes, and formed into individual roofing panels that are ready to be installed on buildings.

- Q: How are steel coils used in the production of automotive exhaust systems?

- Steel coils are used in the production of automotive exhaust systems as they are shaped and formed into various components such as pipes, mufflers, and catalytic converters. These coils are cut, bent, and welded to create the necessary shapes and sizes required for efficient exhaust flow and noise reduction. Additionally, the strength and durability of steel make it an ideal material for withstanding high temperatures and harsh conditions that exhaust systems endure.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Metal Soap Bar

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand varies depending on the specific grade and type of steel being used. Steel is known for its high heat resistance and can typically withstand temperatures ranging from 550°C to 1,100°C (1,022°F to 2,012°F), depending on the grade. However, it is important to note that prolonged exposure to high temperatures can cause steel to lose its structural integrity and result in permanent deformation or even failure. Therefore, it is crucial to adhere to the manufacturer's guidelines and specifications when determining the maximum temperature that steel coils can withstand in specific applications.

- Q: How are steel coils used in the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as a primary material for constructing the appliance's body or frame. The coils are shaped and molded to form the necessary components, providing strength, durability, and stability to the appliance.

- Q: Steel being my favorite type, I just picked up Heart Gold today, my gf got Soul Silver...I was wondering which steel types are available and somewhat easily obtainable in HG (and/or what is the earliest steel type I can get?)

- easiest would be magnemite the good steel types will require some more effort My favorite steel type, scizor, needs a trade with a metal coat... And you don't find metal coat until halfway into the game There's also steelix there aren't that many steel types in the johto generation. There are some good ones in the hoenn so you could transfer from there

- Q: I'm trying to make a corset but I can't find any steel boning in my area. Any clue as to what materials I could buy to to make my own bones, or anything that would work similarly?I know there are places to buy it online, but the cost of shipping makes it barely seem worth it.

- Hi, buy the original bones. They are designed to corset's load. If you use any substitute material it could break and it could be cause of injuries. Use google for link to corset's bones suppliers. Look on:

Send your message to us

RAL Scale Z30 Prepainted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 28000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords