Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

Products Details

1. Chemical Composition and Mechanical Properties(In Quenched & Tempered State)

Material | 4140 | ||

Chemical Composition | Mechanical Properties(In Quenched & Tempered State) | ||

C | 0.38-0.45 | Tensile strength(MPA) | ≥1080 |

Si | 0.17-0.37 | Yield strength (MPA) | ≥930 |

Mn | 0.50-0.80 | Elongation(δ5/%) | 12 |

Cr | 0.90-1.20 | Reduction in Area (ψ/%) | 45 |

Mo | 0.15-0.25 | Impact (J) | 63 |

P | ≤0.035 |

Hardness |

≤217HB |

S | ≤0.035 | ||

Cu | ≤0.30 | ||

Ni | ≤0.30 | ||

2. Product Application Areas

Our products have been used in all kinds of areas, such as aviation,aerospace,navigation,nuclear energy,chemical industry,electronic information,achine manufacture, petrochemical, automotive,instrument and meter, Communication ,transportation, and medical instruments, etc.

3. Similar steel grade & equivalent steel materials

USA | Japanese | Gemany | British | France | International | Chinese |

ASTM&AISI&SAE | JIS | EN DIN | EN BS | EN NF | ISO | GB |

4140 | SCM440 | 42CrMo4 1.7225 | 42CrMo4 1.7225 | 42CrMo4 1.7225 | ------ | 42CrMo |

Product Sales Information

Material | 4140 steel round bar |

Size | Diameter:20mm-1000mm Length:500mm-6000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled,cold drawn,forged |

Surface require | Black,grinding,bright,polish |

Heat treatment | Quenched,Tempered,annealed |

Packing | seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | In 10-50 days |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

MOQ | 1 Ton |

Company Main Products

Alloy Steel | 4140, 4142, 42CrMo4, 1.7225, SCM440, 4130, SCM430, 25CrMo4, 1.7218, 34CrNiMo6, 1.6582, 4340, SNCM439, 36CrNiMo4, 1.6511, SACN645, 1340, SMn438, SNC236, |

Tool Steel | H13, 1.2344, SKD61, D2, SKD11, 1.2379, 1.2510, 01, SKS3, 95MnWCr5, D3, SKD1, 1.2419, SKS31, H21, SKD5, 1.2581, P20, 35CrMo7, 1.2738, 1.2316, M2 |

Bearing Steel | GCr15, 52100, SUJ1, SUJ2, 100Cr6, 1.2067, 55C, 8620, 4320, 9310, 440C, M50 |

Spring Steel | 9260, SUP6, SUP7, 1.7108, 54SiCr6, 1.7102, 5155, SUP9, 1.7176, 5160, 1.7177, 6150, SUP10, 51CrV4, 1.8159 |

Stainless Steel | 321, sus321, 1.4541, 304, SUS304, 1.4301, 410, SUS410, 1.4006, 420, 1.4021, 1.4028, 434, 1.4113, 316L, SUS316L, 1.4435, 630, 1.4542, 431, 1.4057, |

Products Show

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

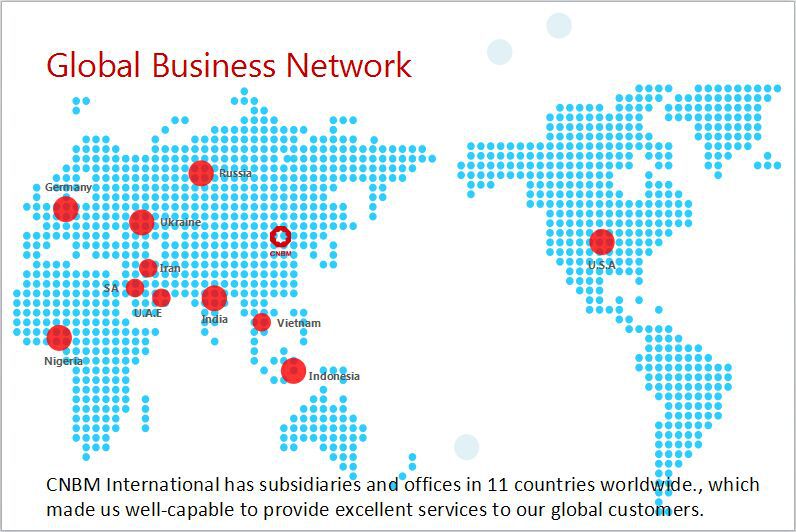

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Can steel round bars be used in food processing applications?

- Using steel round bars in food processing applications is not advisable. These bars are usually crafted from carbon steel, which may contain impurities and fail to meet the required food safety standards. When working with food, it is crucial to utilize materials that are explicitly designed and sanctioned for food contact, like stainless steel. Stainless steel boasts superior resistance to corrosion, ease of cleaning, and non-reactivity with food, preserving its original flavor. Hence, to guarantee the safety and integrity of processed food, it is recommended to employ stainless steel round bars or other food-grade materials in food processing applications.

- Q: Can steel round bars be used in the production of sporting goods?

- Yes, steel round bars can be used in the production of sporting goods. Steel is a durable and strong material that can provide stability and support for various sporting equipment such as weights, bars for weightlifting, poles for pole vaulting, or components for bicycles and golf clubs.

- Q: The difference between 304 stainless steel round bar and bright round bar

- The difference between the stainless steel round bar and the bright round steel of the same material is that the bright circle is cold rolled (or cold drawn), and the black circle is hot rolledThe processing method is different

- Q: Can steel round bars be used in the power generation industry?

- Indeed, the power generation industry does make use of steel round bars. These bars, known for their immense strength and durability, are frequently employed in the construction of power generation equipment and infrastructure. They are particularly valuable in the fabrication of turbine shafts, generator rotors, gears, and other components that require the ability to withstand heavy loads and resist wear and fatigue. Moreover, steel round bars can be readily machined and welded, thereby rendering them a highly versatile material for a wide range of applications in the power generation sector.

- Q: What are the different grades of stainless steel round bars?

- There is a variety of grades available for stainless steel round bars, each with its own unique properties and characteristics. The following are some commonly used grades: 1. Grade 304 is the most commonly used grade for stainless steel round bars. It provides good resistance to corrosion, high durability, and excellent formability. It is suitable for various applications, including food processing equipment, kitchen appliances, and architectural components. 2. Grade 316 is known for its exceptional resistance to corrosion, making it ideal for marine environments or industries where exposure to corrosive substances is common. It also exhibits excellent resistance to high temperatures, making it suitable for heat exchangers and chemical processing equipment. 3. Grade 410 is recognized for its high strength and hardness. It is commonly used in applications that require resistance to corrosion and moderate heat, such as cutlery, pump shafts, and valve parts. 4. Grade 420 contains a higher carbon content, resulting in increased strength and hardness compared to grade 410. It is frequently utilized in the production of surgical instruments, dental tools, and blades. 5. Grade 430 is known for its good corrosion resistance and formability. It is often employed in applications involving decorative trim, automotive components, and kitchen appliances. These examples represent just a few of the available grades for stainless steel round bars. It is crucial to select the appropriate grade based on the specific requirements of your application to ensure optimum performance and durability.

- Q: What are the advantages of using boron-alloy steel round bars?

- The advantages of using boron-alloy steel round bars include increased strength, improved hardness and wear resistance, enhanced toughness, and better heat resistance. Boron-alloy steel round bars also have excellent machinability and can withstand high temperatures without losing their structural integrity. Additionally, these bars offer cost savings due to their longer service life and reduced maintenance requirements.

- Q: What are the advantages of using nickel-chromium-silicon alloy steel round bars?

- There are several advantages of using nickel-chromium-silicon alloy steel round bars: 1. High temperature resistance: Nickel-chromium-silicon alloy steel round bars have excellent resistance to high temperatures, making them ideal for applications that involve exposure to extreme heat. They can withstand temperatures up to 1200°C without losing their strength or structural integrity. 2. Corrosion resistance: These alloy steel round bars have good corrosion resistance, particularly in environments where they are exposed to acids, alkalis, and other corrosive substances. This makes them suitable for use in industries such as chemical processing, oil and gas, and marine applications. 3. High strength and durability: Nickel-chromium-silicon alloy steel round bars have high tensile strength and toughness, which allows them to withstand heavy loads and resist deformation. They are known for their exceptional durability and long service life, even under demanding conditions. 4. Excellent mechanical properties: These alloy steel round bars exhibit excellent mechanical properties, including good ductility, impact resistance, and fatigue strength. This makes them suitable for various applications that require high performance and reliability, such as structural components, machine parts, and tools. 5. Ease of fabrication: Nickel-chromium-silicon alloy steel round bars can be easily machined, welded, and formed into various shapes and sizes. This allows for greater design flexibility and ease of fabrication, making them a preferred choice for manufacturers. 6. Cost-effective: Despite their numerous advantages, nickel-chromium-silicon alloy steel round bars are relatively cost-effective compared to other high-performance materials. Their long service life and resistance to wear and tear make them a cost-efficient choice in the long run, as they reduce the need for frequent replacements and maintenance. Overall, the advantages of using nickel-chromium-silicon alloy steel round bars make them an excellent choice for applications that require high temperature resistance, corrosion resistance, strength, durability, and ease of fabrication.

- Q: Can steel round bars be used in the manufacturing of machinery?

- Yes, steel round bars can definitely be used in the manufacturing of machinery. Steel round bars are widely used in various industries for their strength, durability, and versatility. They are commonly used to create components such as shafts, axles, gears, and other mechanical parts that require high strength and resistance to wear and tear. Steel round bars offer excellent mechanical properties, including high tensile strength and good machinability, which make them suitable for use in heavy machinery and equipment. Additionally, steel round bars can be easily welded, forged, or machined into the desired shape, making them a preferred choice for manufacturing machinery.

- Q: How are steel round bars used in the manufacturing of valves and fittings?

- Steel round bars are used in the manufacturing of valves and fittings as they provide the necessary strength and durability required for these components. The round bars are first machined and shaped into various parts of the valve or fitting, such as the body, stem, or disc. The steel round bars are then further processed through cutting, drilling, and threading to create the desired shape and size. This ensures that the valves and fittings can withstand high pressure, temperature, and corrosive environments, making them suitable for industrial applications.

- Q: What are the different types of steel used for round bars?

- There are several different types of steel used for round bars, including carbon steel, alloy steel, stainless steel, and tool steel. Each type has its own unique composition and properties, making them suitable for various applications and industries.

Send your message to us

Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords