Forged or Hot Rolled Sae 4140 Alloy Steel Round Bars 42CrMO SCM440

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel round bar:

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

Festures of steel round bar:

1.Dia 80-800mm Length:2000-13000mm or as required

2.Technique:Forged

3.Delivery Time:45 days

Specifications of steel round bar:

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

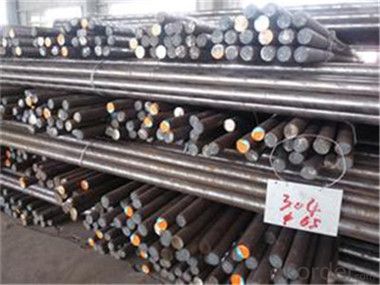

Images of steel round bar:

FAQ:

1. What is your main market?

We mainly export to Asia such as Japan,Korea,Thailand and North America and Middle East.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel round bars be used in the automotive manufacturing?

- Yes, steel round bars can be used in automotive manufacturing. Steel round bars offer high strength and durability, making them suitable for various automotive components such as crankshafts, camshafts, axles, and suspension parts. They also provide excellent machinability and can be easily fabricated into the required shapes and sizes, making them a preferred choice in the automotive industry.

- Q: What are the advantages of using nickel-copper alloy steel round bars?

- Nickel-copper alloy steel round bars offer several advantages. Firstly, their resistance to corrosion and oxidation is excellent, making them ideal for use in harsh environments like the marine or chemical industries. This ensures the longevity and durability of the bars, reducing the need for frequent replacements. Secondly, these round bars have outstanding mechanical properties. The addition of nickel and copper enhances their strength, toughness, and hardness, making them suitable for heavy-duty applications in construction, manufacturing, and engineering. They can withstand heavy loads and resist deformation or breakage, contributing to the overall safety and reliability of the structures or components they are used in. Another advantage is their excellent thermal stability. The alloy has a low coefficient of thermal expansion, allowing it to withstand high temperatures without significant dimensional changes. This is particularly important in applications involving extreme heat, such as in the aerospace or power generation industries. The thermal stability of the bars ensures their dimensional integrity, reducing the risk of warping or cracking under high-temperature conditions. Furthermore, Nickel-copper alloy steel round bars offer good electrical conductivity. This is beneficial in applications that require the transmission of electric current, such as electrical wiring or power distribution systems. The high electrical conductivity of the alloy ensures efficient and reliable electrical connections, minimizing power loss and maximizing performance. In conclusion, the advantages of nickel-copper alloy steel round bars include excellent corrosion resistance, superior mechanical properties, thermal stability, and good electrical conductivity. These characteristics make them suitable for a wide range of applications in various industries, providing durability, strength, and reliability.

- Q: What are the typical yield strengths of different grades of steel round bars?

- The specific grade of steel can cause the yield strength of steel round bars to vary. Here are some common yield strengths for different grades of steel round bars: - Mild steel round bars usually have a yield strength of approximately 250 MPa (megapascals) or 36,000 psi (pounds per square inch). - The yield strength of carbon steel round bars can range from 350 to 550 MPa or 50,000 to 80,000 psi. - Compared to mild or carbon steel, alloy steel round bars such as 4140 or 4340 generally have higher yield strengths. The yield strength of these alloys can vary from 550 to 850 MPa or 80,000 to 120,000 psi. - Stainless steel round bars are available in different grades, and their yield strengths can vary accordingly. For instance, austenitic stainless steels like 304 or 316 usually have yield strengths ranging from 200 to 300 MPa or 29,000 to 43,000 psi. Conversely, duplex stainless steels like 2205 or 2507 can have higher yield strengths of 450 to 650 MPa or 65,000 to 95,000 psi. It is important to keep in mind that these values are typical ranges, and the actual yield strength of a specific grade of steel round bar may differ due to factors such as heat treatment, manufacturing process, and other variables. Therefore, it is always advisable to consult the manufacturer's specifications or industry standards for accurate and precise yield strength values of steel round bars.

- Q: Can steel round bars be coated?

- Indeed, it is possible to coat steel round bars. Coating them yields numerous advantages, such as enhanced resistance to corrosion, increased durability, and improved visual appeal. The most commonly utilized coatings for steel round bars encompass galvanized coatings, epoxy coatings, and powder coatings. Galvanized coatings encompass the application of a zinc layer onto the steel's surface, which provides exceptional protection against corrosion. Epoxy coatings, on the other hand, find common application in industrial settings due to their remarkable chemical resistance and ability to withstand harsh environments. Powder coatings, involving the electrostatic application of a dry powder, are then cured under heat to form a robust and protective layer. These coatings can be employed on steel round bars to safeguard against rust and other forms of corrosion, thereby rendering them suitable for a broad scope of applications across various industries, including construction, manufacturing, and automotive.

- Q: Are steel round bars suitable for agricultural applications?

- Yes, steel round bars are suitable for agricultural applications. They possess strong structural integrity, durability, and resistance to corrosion, making them ideal for various agricultural uses such as fencing, livestock handling equipment, and machinery parts. The versatility and reliability of steel round bars make them a popular choice in the agricultural industry.

- Q: What are the advantages of using high-strength steel round bars?

- Using high-strength steel round bars in various applications brings several advantages. Firstly, these bars have an exceptional strength-to-weight ratio. Despite being lighter than other materials, they possess significantly higher strength. This advantage allows for the construction of sturdy and lightweight structures, making them ideal for weight reduction in industries like aerospace and automotive. Secondly, high-strength steel round bars offer excellent resistance to wear, fatigue, and impact. This makes them highly durable and able to withstand heavy loads and repeated stress, enhancing the lifespan and performance of structures or components. This is particularly beneficial in construction, where materials must maintain structural integrity over time. Furthermore, high-strength steel round bars provide improved design flexibility due to their versatility. They can be easily shaped, machined, and welded, allowing for the creation of complex and customized structures or components. This enables engineers and designers to optimize their designs and achieve specific performance requirements. In addition, high-strength steel round bars offer enhanced resistance to corrosion, making them suitable for applications in harsh environmental conditions. By utilizing these bars, structures or components can maintain their integrity and functionality for extended periods, reducing the need for frequent maintenance and replacement. Finally, using high-strength steel round bars can lead to long-term cost savings. Despite their higher initial cost, their superior strength and durability significantly reduce maintenance, repair, and replacement costs over time. Additionally, their lightweight nature contributes to fuel efficiency, resulting in cost savings in transportation and other industries. Overall, the advantages of using high-strength steel round bars include a high strength-to-weight ratio, excellent resistance to wear and fatigue, improved design flexibility, enhanced corrosion resistance, and potential cost savings. These benefits make them a preferred choice for a wide range of applications.

- Q: Can steel round bars be used in the production of fasteners?

- Yes, steel round bars can be used in the production of fasteners. Steel round bars are commonly used as a raw material in the manufacturing of various types of fasteners such as bolts, screws, nuts, and studs. The round shape of steel bars allows for easier machining and forming processes required to create threaded or non-threaded fasteners. Steel is a popular choice for fasteners due to its strength, durability, and resistance to corrosion. Additionally, steel round bars can be easily heat-treated to improve their mechanical properties, making them suitable for a wide range of fastening applications in various industries.

- Q: What are the advantages of using nickel-lead alloy steel round bars?

- There are several advantages of using nickel-lead alloy steel round bars: 1. Enhanced corrosion resistance: Nickel-lead alloy steel round bars exhibit excellent corrosion resistance, making them suitable for use in various industries, especially those dealing with harsh environments or corrosive substances. This property ensures the longevity and durability of the bars, reducing the need for frequent replacements. 2. Superior strength and toughness: The inclusion of nickel and lead in the alloy composition enhances the strength and toughness of the steel round bars. This makes them highly resistant to deformation, cracking, and wear, even under high-stress conditions. As a result, these bars can withstand heavy loads and impacts, making them ideal for applications that require robust and reliable materials. 3. Improved machinability: Nickel-lead alloy steel round bars possess excellent machinability, allowing for easy cutting, drilling, and shaping during fabrication processes. The alloy's composition enables efficient chip evacuation and reduces tool wear, resulting in increased productivity and cost-effectiveness in manufacturing operations. 4. Thermal stability: Nickel-lead alloy steel round bars exhibit excellent thermal stability, making them suitable for applications that involve high temperatures or extreme thermal cycling. These bars can withstand thermal expansion and contraction without experiencing significant dimensional changes, ensuring dimensional accuracy and structural integrity over time. 5. Low coefficient of friction: The addition of lead to the alloy composition contributes to a low coefficient of friction, reducing friction and wear between the bars and other surfaces. This property is particularly valuable in applications where minimal wear and lubrication are essential, such as in bearings or sliding components. 6. Electrical conductivity: Nickel-lead alloy steel round bars possess good electrical conductivity, making them suitable for applications that require efficient electrical current flow. This property is beneficial in electrical connectors, circuit breakers, and other electrical components, where reliable conductivity is crucial. In summary, the advantages of using nickel-lead alloy steel round bars include enhanced corrosion resistance, superior strength, improved machinability, thermal stability, low friction coefficient, and good electrical conductivity. These properties make them an excellent choice for a wide range of applications in various industries.

- Q: Are steel round bars used in the automotive industry?

- Steel round bars are widely utilized in the automotive industry. They find their application in diverse areas like the production of engine components, suspension systems, chassis, and axles. Due to their exceptional strength, durability, and versatility, steel round bars are highly favored for automotive parts that demand exceptional performance and reliability. Moreover, steel's capacity to endure heavy loads and its resistance to deformation make it well-suited for critical automotive applications prioritizing safety.

- Q: Can steel round bars be used in the oilfield equipment industry?

- Yes, steel round bars can be used in the oilfield equipment industry. Steel round bars are commonly used in the manufacturing of various components and structures in the oilfield equipment industry due to their strength, durability, and resistance to corrosion. These bars are often utilized in the construction of drilling tools, pipe fittings, valves, and other equipment needed for oil exploration, extraction, and transportation.

Send your message to us

Forged or Hot Rolled Sae 4140 Alloy Steel Round Bars 42CrMO SCM440

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords