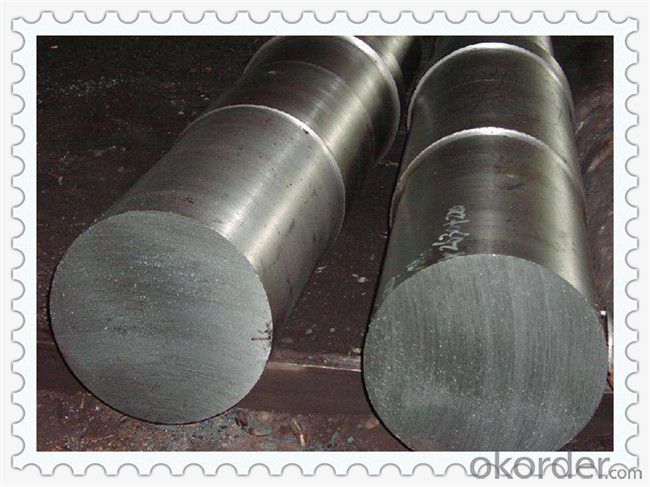

SCM440 SCM415 SAE4140 Steel Round Bar /AISI 4140 Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SCM440 SCM415 SAE4140 Steel Round Bar /AISI 4140 Steels

1. Dia:12mm-300mm

2. Standard Performed: ASTM A29/A29M-04

3. Equal Standard:

America Standard: AISI4140

International Standard: 42CrMo4

Japan Standard: SCM440

Germany Standard: 42CrMo4

4. Chemical composition:

Grade | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Al |

AISI4140 | 0.38 0.41 | 0.15 0.35 | 0.85 1.00 | Max 0.015 | Max 0.040 | Max 0.25 | 0.80 1.10 | 0.15 0.25 | Max 0.35 | 0.012 0.030 |

5. Grade: ASTM A29 4140 42CrMo SCM440

Hardness:217HB

Tensile strength:1080(110)MPA

Yield strength: 930(95)MPA

Elogation: 12%

Reduction of area: 45%

AKV(impact value): 63J

- Q: Are steel round bars suitable for welding?

- Yes, steel round bars are suitable for welding.

- Q: Can steel round bars be used in the manufacturing of machinery?

- Certainly, machinery manufacturing can make effective use of steel round bars. Various industries commonly employ steel round bars due to their robustness, longevity, and adaptability. These bars frequently serve in the fabrication of essential components like shafts, axles, gears, and other mechanical parts that necessitate exceptional strength and resistance against deterioration. Notably, steel round bars exhibit remarkable mechanical properties, encompassing impressive tensile strength and superior machinability, rendering them highly suitable for heavy-duty machinery and equipment. Furthermore, steel round bars can be conveniently welded, forged, or machined into the desired configuration, thus establishing them as a preferred option for machinery manufacturing.

- Q: What is the maximum hardness achievable for steel round bars?

- The maximum hardness attainable for steel round bars relies on various factors, including the steel's composition, the heat treatment process, and the desired properties for the specific application. Typically, steel can reach a maximum hardness of approximately 65 HRC or higher. This level of hardness is commonly achieved through procedures like quenching and tempering. Quenching entails rapidly cooling the steel from a high temperature to room temperature, resulting in a hardened structure. Subsequently, tempering is carried out to decrease brittleness and enhance the steel's toughness while maintaining a high level of hardness. It is crucial to acknowledge that pushing the hardness of steel beyond a certain point may result in reduced toughness and increased brittleness. Hence, the maximum attainable hardness must be balanced with the desired properties for the particular application, such as strength, ductility, and resistance to wear or impact.

- Q: Can steel round bars be used for making transmission components?

- Yes, steel round bars can be used for making transmission components. Steel is a widely used material in the manufacturing industry, and it offers excellent strength, durability, and resistance to wear and tear. Round bars made of steel are commonly used in the production of transmission components such as gears, shafts, and couplings. The steel round bars are often machined or forged into the desired shape and then heat-treated to enhance their mechanical properties. The use of steel round bars ensures that the transmission components can withstand high loads, provide smooth power transmission, and have a long service life.

- Q: Can steel round bars be used in the aerospace industry?

- Yes, steel round bars can be used in the aerospace industry. Steel round bars are commonly used in various aerospace applications such as structural components, engine parts, landing gear, and fasteners due to their high strength, durability, and resistance to corrosion.

- Q: Can steel round bars be used in the construction industry?

- Steel round bars have become a common choice in the construction industry due to their versatility and wide usage in various structural applications. These bars possess high strength and durability, making them suitable for providing structural stability and supporting heavy loads in buildings, bridges, and other construction projects. In concrete structures, such as columns, beams, and slabs, steel round bars can be utilized as reinforcement to enhance their strength and resistance against bending or cracking. Moreover, the construction industry often relies on steel round bars for the fabrication of steel frameworks, scaffolding, and other support systems. The availability of these bars in different sizes and grades allows for flexibility in meeting specific construction requirements. In summary, steel round bars are an essential component in the construction industry, thanks to their strength, versatility, and ability to withstand demanding conditions.

- Q: Can steel round bars be used in the manufacturing of shafts?

- Yes, steel round bars can be commonly used in the manufacturing of shafts. Steel round bars possess excellent strength, durability, and resistance to wear and tear, making them ideal for shaft applications. Additionally, their round shape allows for easy machining and shaping into the desired dimensions and specifications required for shafts.

- Q: What are the applications of steel round bars?

- Due to their inherent strength, durability, and versatility, steel round bars find extensive applications across various industries. They play a crucial role in: 1. Construction: Steel round bars are widely used in the construction industry for structural purposes. They provide stability and safety in building columns, beams, and frames due to their high strength-to-weight ratio. 2. Manufacturing: The manufacturing sector heavily relies on steel round bars for fabricating components and machinery. They are essential in producing gears, shafts, axles, and other machine parts that demand precision and strength. 3. Automotive industry: Steel round bars are significant in manufacturing crankshafts, connecting rods, suspension components, and other automobile parts. They contribute to the strength and reliability of vehicles. 4. Oil and gas industry: The oil and gas sector utilizes steel round bars in manufacturing drill bits, valves, pipes, and equipment exposed to harsh environmental conditions. These bars offer high strength and corrosion resistance. 5. Aerospace industry: The aerospace industry heavily depends on steel round bars for their high strength and lightweight properties. They are used in aircraft components such as landing gear, engine parts, and structural elements. 6. Shipbuilding: Steel round bars are commonly employed in shipbuilding due to their excellent strength and corrosion resistance. They are used in constructing ship frames, hulls, and critical components that require durability in harsh marine environments. 7. Infrastructure projects: Steel round bars are extensively used in infrastructure projects like bridges, tunnels, and railways. They provide the necessary strength and stability to support heavy loads and ensure the structural integrity of these projects. 8. Furniture and interior design: Steel round bars also find applications in the furniture and interior design industry. They are commonly used in the construction of chairs, tables, shelves, and other furniture pieces due to their sleek appearance, durability, and ease of molding. In conclusion, steel round bars have a wide range of applications in various industries, contributing to the development of robust and reliable structures, machinery, and equipment.

- Q: Can steel round bars be used in the manufacturing of heat exchangers?

- Heat exchangers can indeed utilize steel round bars in their manufacturing process. Due to its exceptional strength and thermal conductivity, steel is frequently employed in the construction of heat exchangers. By shaping and welding steel round bars, a range of sizes and forms can be achieved, enabling the creation of crucial heat exchanger elements like tubes, headers, and baffles. Furthermore, the durability and corrosion resistance of steel make it an ideal choice for numerous industrial applications that demand efficient heat transfer.

- Q: What are the different machining processes used for steel round bars?

- Some of the different machining processes used for steel round bars include turning, milling, drilling, and grinding. Turning involves rotating the bar against a cutting tool to remove material and create a desired shape. Milling uses a rotating cutter to remove material from the surface of the bar. Drilling involves creating holes in the bar using a rotating drill bit. Grinding uses an abrasive wheel to remove material and achieve a smooth surface finish on the bar. These processes are commonly used in metalworking industries to shape and refine steel round bars for various applications.

Send your message to us

SCM440 SCM415 SAE4140 Steel Round Bar /AISI 4140 Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords