QTZ50(4810B) tower crane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTZ50(4810B) tower crane is hoisting and conveying machinery which is designed by Shandong Fuyou Co., Ltd. by fully utilizing the group technology, the combinational design technology and the finite element analysis technology and taking the tower crane microcomputer design platform as a tool and has excellent performance.

The crane is a horizontal-arm-rest trolley-amplitude upper-revolution hydraulic lifting type crane which has the effective amplitude of 48m and the maximum lifting moment of 544kN•m. The tower crane has the lifting height of 30m and the adhesion lifting height of 120m (2 magnification) during independent use.

All the speed indexes of the crane meet or surpass national standards.

The crane has the total installed capacity of 24.9kW, features advanced parameters, excellent and reliable properties, attractive appearance, high quality, simple and practical structures, advanced safety devices, convenient maintenance, safe usage and reasonable prices, and is ideal construction machinery for many medium-small construction enterprises.

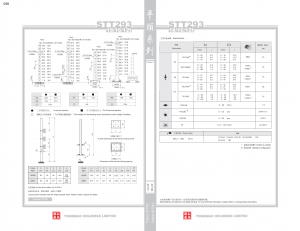

2. Lifting Technical Performance

2.1 Lifting Performance Table and Lifting Performance Curve

(1) 4-magnification Lifting Performance Table

The lifting boom and balance boom adopt cantilever boom structure, which reduces the hoisting modular and makes it more safe, convenient and flexible to install and uninstall, and reduces the requirements for hoisting equipment and the site.

2. Multiple special mounting brackets are available, which saves the installation time and ensures safe and quality installation.

3. The lifting boom adopts cantilever boom structure and variable cross-section materials, featuring more reasonable structural stress and long service life; and it is easier to make different combination of boom length.

| Amplitude(m) | 3-13.6 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

Lifting capacity(kg) | 4000 | 3890 | 3618 | 3380 | 3170 | 2860 | 2810 | 2660 | 2530 | 2400 | 2290 |

Amplitude(m) | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 |

Lifting capacity(kg) | 2190 | 2090 | 2000 | 1920 | 1850 | 1770 | 1710 | 1650 | 1590 | 1540 | 1490 |

Amplitude(m) | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 |

Lifting capacity(kg) | 1440 | 1390 | 1350 | 1310 | 1270 | 1230 | 1200 | 1170 | 1130 | 1100 | 1070 |

Amplitude(m) | 46 | 47 | 48 | ||||||||

Lifting capacity(kg) | 1050 | 1020 | 1000 |

(2)2-magnification Lifting Performance Table

Amplitude(m) | 3-26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 |

Lifting capacity(kg) | 2000 | 1920 | 1850 | 1770 | 1710 | 1650 | 1590 | 1540 | 1490 | 1440 |

Amplitude(m) | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 |

Lifting capacity(kg) | 1390 | 1350 | 1310 | 1270 | 1230 | 1200 | 1170 | 1130 | 1100 | 1070 |

Amplitude(m) | 46 | 47 | 48 | |||||||

Lifting capacity(kg) | 1050 | 1020 | 1000 |

Technical Performance Parameter Table

Item | Unit | Magnification | ||

α=2 | α=4 | |||

Rated lifting moment | kN.m | 500 | ||

Maximum lifting capacity | t | 2 | 4 | |

Working amplitude | m | 3 ~48 | ||

Maximum amplitude lifting capacity | t | 1.0 | ||

Lifting height | Independent | m | 30 | |

Attached | m | 120 | ||

Time of moving outrigger end to rotation center | m | 48.74 | ||

Time of moving balance arm tail to rotation center | m | 12.816 | ||

Counter weight | t | 7 | ||

Total motor power | kW | 24.9 | ||

Allowable working temperature | 0C | -20~+40 | ||

- Q: I currently have 1999 origami paper cranes. And I haven't made my 2000th yet because I don't know what to wish for :3So I wanna know...Do you have to make your wish right on the 1000th one? Or can you make the 1000th one and save it until you think of something good to wish for.I'm serious. :3

- wait, you folded 1999 paper cranes and you still didn't have enough time to come up with a wish? I recommend that you wish to become more decisive...

- Q: What species of crane/heron is at 3:07 of this video?

- It is a stork, not a crane or heron. The painted stork, Mycteria leucocephala. The first pic in this link does not make the identification clear..

- Q: Is there anything similar to the traditon where you fold 1000 origami cranes and you get a wish?

- The 1000 paper cranes thing really only became popular after the 2nd world war- a girl in Japan was told she woudl have a wish granted if she did it in a lifetime. She had been a victim of hiroshima (or nagasaki, i forget), so she gave it a shot but ended up dying young from the illness before she reached her quota. The point is, if it does exist in other cultures, it'll likely only be a surface similarity, I'd imagine. I remember reading in a children's book once that every leaf you catch from a tree in the fall before it touches the ground counts as a day's good luck... but i dont know if that's an actual superstition or one made up for the story. I can't remember the name of it either...

- Q: Operation points of tower crane (tower crane)?

- Slewing bearing: tower crane is one of the most critical components, mainly to bear overturning moment and vertical load. After the failure, the demolition and replacement is extremely difficult, loss of large, so you have to check carefully to do maintenance, each 200H must be a senior grease lubrication from the rotary bearing surface, until now exudation. Slewing bearing adopts high strength bolt connection, if the pretension is not enough, or long-term operation, do not check, not fastening, will cause loose. If the individual bolts loose, will cause the remaining bolts overload, the consequences will be disastrous. The luffing mechanism only moves horizontally, the load is light and the line speed is not high, so it should be easy to master and operate. However, the amplitude involves the change of the lifting torque, and if there is no stopping in time, there will be the possibility of over torque. Therefore, the main requirement of variable amplitude operation is stationary parking and accurate positioning. The tower crane is of great height and the hanger is hung longer, so it is easy to swing the hanger when it is running. This is an objective phenomenon. What is called stabilization hook operation is how to make the swinging hook stop quickly, or how to make the hook move with the movement of the crane as soon as possible, and minimize the operation of the swing. The operation of stabilization hook is the skill that the driver should master.

- Q: What is tower crane? What are the types and features?

- [classification and characteristics]Tower crane is divided into two categories: upper slewing tower and lower slewing tower crane. Among them, the bearing capacity of the former is higher than that of the latter. In many construction sites, what we have seen is the tower crane with rotary top, top lift and knot joint.

- Q: Do some schools of hung gar only teach (or focus on) the tiger crane form?

- I don't think so, not if it is taught as a complete system, then it should offer more than just tiger/crane form.

- Q: Where are levers used in and throughout the crane

- No. A lever requires a fulcrum and a boom has none. As ststed the levers are used to operate the hoisting mechanism.

- Q: All these birds are bigger than wild turkey and can fly long distances.

- Not answerable as you do not indicate in what area you are considering, weight, wingspan, height? Even in weight it is controversial. The mute swan and Andean Condor weigh in at around 30 pounds. In height it would be the Crane. And wingspan would be the Albatross.

- Q: Brief introduction of ten no hanging criterion for tower crane operation

- 1, hanging weight more than no mechanical properties allow the crane; 2, the command signal is unknown, the weight is unknown, the dim light to hang; 3 working face, stand or floating active objects not hanging;

- Q: The machine weight is 17500 KgEach crane capacity is 12500 KgThe lenght of beam is 4.5m and square cross section areaMaterial of beam is ASTM A 615 Gr60Machin connect to beam in 3 pointWhat is the beam cross section area dimension?

- You left out crucial information and working it out with risky assumptions takes too much work. Whatever this was supposed to mean Machin connect to beam in 3 point What is missing is whether the cranes connect to the end and the entire weight of the machine is in the middle - or is the machine attached at 3 distributed points. In addition, there has to be some condition - looking at the ASTM spec will give strength, but you have specified whether the beam is to be just at failure or 50% safety factor, etc.

Send your message to us

QTZ50(4810B) tower crane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords