Quality Aluminum Coil - PVDF Color Coated Aluminium Coil AA3003 Temper H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PVDF Color Coated aluminium coils are widly used in decoration in the open air. The painting can last about 15-20 years. Now many Asian countries are choosing this product instead of steel products. For the painting brand, we can provide China brand, North American PPGI and European brand Becker. Usually our customers from European prefer Becker.

2. Main features of the product

a.Competitive price--CNBM have own mills, so we can provide more competitive price than those small suppliers.

b.Professional after-sale service--We have more than 20 years exportation experience, you can get most professional service from CNBM.

c.Fast delivery time--Usually our delivery time is about 30 days.

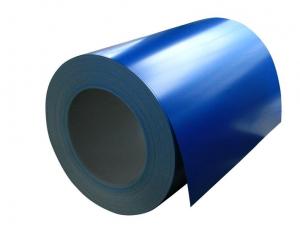

3. Image

4.Product Specification

| Alloy | Temper | Painting | Coil ID | Coil Weight | Last Time |

| AA3003 | H14 | PVDF | 505MM | Max 2.65 tons | 15-20 years |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is your MOQ for this product?

---Usually we can do 5 tons for every size.

- Q: Are aluminum coils suitable for architectural façade systems?

- Yes, aluminum coils are suitable for architectural façade systems. Aluminum is a lightweight and durable material that offers excellent corrosion resistance and can be easily shaped and formed into various designs. It is widely used in architectural applications due to its versatility, strength, and aesthetic appeal. Additionally, aluminum coils can be coated with different finishes to enhance their appearance and provide protection against weathering, making them an ideal choice for architectural façade systems.

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are commonly used as the base material for manufacturing aluminum composite panels, which are then used in various applications including ceilings. The coils are processed and coated to meet the desired specifications and aesthetics of the composite ceiling panels.

- Q: How are aluminum coils coated for color matching and aesthetic purposes?

- The process of coil coating is commonly used to coat aluminum coils for color matching and aesthetic purposes. It is a continuous and highly automated process where a layer of paint or coating is applied onto the surface of the aluminum coil. To start the coil coating process, the aluminum coil is thoroughly cleaned to remove dirt, grease, and oxidation. This is done using chemical cleaning agents and mechanical scrubbing methods to ensure a clean and smooth surface. Once the cleaning process is complete, a primer is applied to the aluminum coil. The primer acts as a bonding agent, improving the adhesion of the subsequent layers of paint or coating. It also helps to prevent corrosion on the aluminum surface. After the primer is applied, the aluminum coil undergoes a series of rollers where the desired color coating is applied. This can be done through various methods such as coil coating, spray coating, or powder coating. Coil coating is the most common method, involving the application of a liquid paint or coating onto the metal coil surface. The coating is then cured or dried using heat to ensure proper adhesion and durability. In order to achieve color matching and aesthetic purposes, the paint or coating used is often customized to specific color palettes or customer requirements. This customization is achieved by using a wide range of pigments and additives that alter the color, texture, and gloss level of the coating. Furthermore, specialized coatings can be applied to aluminum coils to enhance their aesthetic properties. For example, there are coatings available that give the appearance of natural wood or stone, providing a more visually appealing finish. Overall, the process of coating aluminum coils for color matching and aesthetic purposes involves thorough cleaning, priming, and the application of customized paint or coatings. This ensures that the aluminum coils meet the desired aesthetics while also providing durability and protection against corrosion.

- Q: I don't have a rounded baking tray at the moment and would like to replace it with aluminium foil, do you think it's suitable and that it can withheld the intensity?

- Should be fine

- Q: How much of a difference does it make? I recently bought a 700 SPS tactical in 308. It has the Houge pillar bedding stock. I love the tacky feeling rubber outside, but noticed that the fore end of the stock flexes a bit (enough to touch the free floating barrel.) I was wondering if the aluminum bedding block version of the same stock (or any other aluminum bedding stock) will be better? I know they cost more, and the experts claim they're great, but will an amateur shooter notice the difference? I like to target shoot, typically around 200 yards. BTW, I was also considering the Bell and Carlson medalist.

- Vote for the Aluminum yet somewhat might like a silver lined one bless by using a Catholic priest that emits holy water. That way in case they are additionally a vampire you nailed them.

- Q: How do aluminum coils perform in extreme temperature conditions?

- Aluminum coils exhibit satisfactory performance in extreme temperature conditions. With a high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), aluminum is well-suited for handling high temperatures. Additionally, its exceptional thermal conductivity allows for efficient heat transfer and rapid cooling in extreme heat situations. This characteristic proves particularly advantageous in applications like air conditioning systems and refrigeration units, where aluminum coils are commonly utilized. Furthermore, aluminum is renowned for its corrosion resistance, a quality that is vital in extreme temperature settings. It resists oxidation and does not easily succumb to rust, ensuring the durability and longevity of the coils. This resistance to corrosion is especially significant in environments characterized by high humidity or exposure to salt, where alternative metals may rapidly corrode. Nevertheless, it is important to note that the performance of aluminum coils may be affected by extremely cold temperatures. In such conditions, aluminum contracts and becomes more brittle, potentially leading to reduced flexibility and even cracking. Consequently, it becomes crucial to provide proper insulation and protection to prevent any damage to the coils in extremely cold surroundings. Overall, aluminum coils can be relied upon and demonstrate commendable performance in extreme temperature conditions, particularly in applications involving high temperatures. Their high melting point, excellent thermal conductivity, and resistance to corrosion render them suitable for a wide range of industries and environments.

- Q: Can aluminum coils be used for decorative purposes?

- Aluminum coils offer a multitude of possibilities when it comes to decoration. This versatile material can be easily molded and adjusted, making it ideal for a wide range of decorative uses. In industries like architecture, interior design, and automotive design, aluminum coils are frequently employed to create decorative trims, accents, and borders. To further enhance their visual appeal and match the desired aesthetic, these coils can be painted or coated with different finishes. Moreover, thanks to their lightweight nature and durability, aluminum coils are a popular choice for outdoor decorative purposes, such as garden ornaments, sculptures, and signage. Ultimately, incorporating aluminum coils into various projects provides a cost-effective and visually pleasing solution for adding decorative elements.

- Q: How are aluminum coils used in electrical applications?

- Aluminum coils are widely used in various electrical applications due to their advantageous properties. These coils are primarily used in transformers, motors, and inductors. In transformers, aluminum coils are used to transfer electrical energy from one circuit to another. The coils are wound around a magnetic core, which helps in the efficient transfer of energy. Aluminum coils are preferred over copper coils in transformers due to their lower cost, lightweight nature, and excellent conductivity. Additionally, aluminum coils have a higher thermal conductivity, allowing for better heat dissipation, which is crucial in maintaining the efficiency and longevity of transformers. In motors, aluminum coils are used as the winding material for the stator. The stator is the stationary part of the motor, and the coils generate a magnetic field when an electrical current is passed through them. This magnetic field interacts with the rotating magnetic field generated by the motor's rotor, resulting in the rotation of the motor. Aluminum coils are preferred in motors due to their lightweight nature, which reduces the overall weight of the motor, making it more efficient. Inductors are another electrical component that utilizes aluminum coils. Inductors store electrical energy in the form of a magnetic field. When current flows through the coil, a magnetic field is created, which resists changes in the current. Aluminum coils are used in inductors due to their high electrical conductivity, which allows for efficient energy storage and release. Overall, aluminum coils are extensively used in electrical applications due to their cost-effectiveness, lightweight nature, excellent conductivity, and high thermal conductivity. Their usage in transformers, motors, and inductors contributes to the efficient and reliable operation of electrical systems.

- Q: Can aluminum coils be welded or soldered?

- Yes, aluminum coils can be welded or soldered. Welding and soldering are two common methods used to join aluminum coils together. Welding involves melting the aluminum material in the coils and fusing them together using heat and pressure. This process requires specialized equipment and skilled operators. On the other hand, soldering is a process that uses a lower melting point filler material, called solder, to join the aluminum coils. Soldering is typically used for lighter applications and requires less heat than welding. Both welding and soldering can effectively join aluminum coils, but the choice between the two methods depends on the specific requirements of the project, the equipment available, and the expertise of the operator.

- Q: How do aluminum coils compare to stainless steel coils in terms of durability?

- Aluminum coils are generally less durable than stainless steel coils. While aluminum coils are lightweight and corrosion-resistant, they are prone to denting and are not as strong as stainless steel. On the other hand, stainless steel coils are highly durable, resistant to dents, and have a longer lifespan.

Send your message to us

Quality Aluminum Coil - PVDF Color Coated Aluminium Coil AA3003 Temper H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords