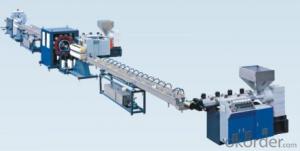

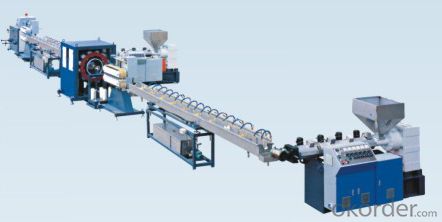

PVC Fiber Reinforced Hose Machine Extrusion Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Fiber Reinforced Hose Machine Extrusion Production Line

Production Description

PVC fiber reinforced hose also named PVC network tube, commonly known as plastic snakeskin tube, transparent, portable, with high tensile strength, and good resistance to high pressure, hardening and erosion, beautiful looks, and nontoxicin foodstuffs and sanitation lines

main uses

It is really the best choice for conveying air ,water, gas, oil and some other liquid and gas material with its working temperature ranges from-5 to 65.

now also widely used in pouring the garden ,lawn.Suitable for conveying the pressure or corrosive gas, liquid .widely used in the machinery , coal mineral , petroleum .chemical industry ,agriculture irrigation ,construction, civil (solar water heater ,gas cylinder)etc.

Machine configuration

exturder | 2sets |

Cooling tank | 2sets |

Hauling machine | 2sets |

Winding machine | 1set |

mould | 1set |

Coiling pipe bender | 1set |

drier | 1set |

High speed kneading machine | 1set |

Technical parameters

Model | YG-XW65 | YG-XW45 |

Extruder | XW65/28 | XW45/28 |

Screw material | 38CrMoALA | |

Screw rotate speed(r/min) | 0-70 | |

Diameter Range(mm) | Φ12-Φ50 | Φ6-Φ14 |

Output (kg/h) | 40-75 | 40-90 |

Installed Power(KW) | 50 | 35 |

Hauling speed(m/min) | 0-18 | |

Weight(kg) | 6000 | |

Process flow:

High speed kneading machine (mixing materials)---mould---extruder 1(innermost layer PVC pipe)------cooling tank 1---hauling machine 1 ---winding machine (fiber line that is the second)---dryer---extruder 2(the most outer PVC pipe )----cooling tank 2---hauling machine 2---coiling pipe bender ----package.

promise:

Our Company has more than 10 years in the field of PVC machine .NO.1 machine quality ,

competitive price ,and excellent after sales service ,will make you covince

If you have any question .feel free to contact me

looking forward to cooperate with you in near future.

- Q: It's a small plastic shell for the processing plug! How much is the small injection molding machine 100Which great God knows what equipment a small plastic shell needs?! It's a small plastic shell for the processing plug! How much is the small injection machine?! Where does Wuxi sell injection molding machine?!

- I'm a little far from your territory. I'm in Guangdong and I have a lot here. You go to Alibaba network to find a lot of, this device in China has been very popular.

- Q: Types of plastic machinery

- Characteristics of injection molding machine control system:1. 、 adopt advanced computer control of famous factory;2. self diagnostic fault function;3. direct input pressure, speed, time, travel and temperature data;4.LCD color liquid crystal display (pictured below);5. centralized lubrication;6. pressure coupling circuit saves power;7.24 V DC oil pressure directional valve coil never damaged;8. die cooling water regulator;9.M.C.B. insurance electrothermal control;10. advanced computer control system, large screen display, operation interface, easy to use cylinder;11. high-precision electronic ruler stroke control, accuracy up to + 0.1mm;12. improve reproducibility by using pressure and oil feedback;13. mechanical, electrical, hydraulic 3 heavy safety devices, in any case can ensure the safety of the operator (PD60-PD148 matching oil pressure);14. improve the reproducibility and operability by installing superior position sensors;15. using closed-loop control to achieve ultra precision forming.

- Q: What plastic products do you have and what's the use of it?

- Industry: Electrical and electric industry in making extensive use of plastic insulating materials and packaging materials;

- Q: What are the processes and machines used in the manufacture of plastic products?,

- In recent years, the proportion of plastic products is increasing rapidly in many fields, such as household appliances, instruments and meters, building materials, automobile industry, daily hardware and so on. The requirement of high precision and high performance of plastic products increases with each passing day, which makes the precision forming technology progress constantly. Injection molding is one of the most important plastic forming methods, and many factors affect the precision injection molding. 1. in the early stage of the design of plastic products, injection molding materials should be selected according to their application environment. 2. precision molds, rational design of precision injection mold is the basis and necessary prerequisite for precision products. Precision molds are indispensable to produce precision products. The precision of the die is usually affected by the temperature control of the die, the precise manufacture of the die and the choice of the plastic shrinkage when the die is designed. 2.1 control of the mold temperature due to the effect of mold temperature on shrinkage molding, but also directly affects the mechanical properties of plastic products, can also cause various defects of product surface flooding, so must keep mold in the specified temperature range, but also to make the mold temperature changes over time. In the injection molding of general precision parts, the temperature of the die is controlled mainly to increase productivity. But the impact of temperature control of mold for injection molding is great, it affects parts of the shrinkage, shape, crystallization, internal stress, so the design of mold hot loop temperature distribution at the request reasonable precise control accuracy, the best use of mold temperature machine and cold water machine control.

- Q: Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: What kind of equipment do you need and how much will it cost to invest?

- Public plastic trash cans are medium sized plastic products. This mold general manufacturing plastic barrels in order to stabilize and consider the need of square cooling, iron mould 150MM wide 300MM deep, so just open a mold if at least 30 thousand + words, injection molding machine molding capacity to get at the mold injection molding requires a minimum of 10 kg, which belongs to the large injection molding machine.

- Q: The difference between plasticization and processability of plastics in extrusion process

- I. Introduction of extruderIn the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation. The basic mechanism of extrusion is very simple a screw in the cylinder to rotate and move forward the plastic. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.

- Q: Every time I look for work on the Internet, I am confused. What kind of industry does the plastic belong to?..

- According to the latest "national economic industry classification (GB/T 4754-2011)", the plastic products industry belongs to the C category manufacturing industry, the 29 major categories of rubber and plastic products industry, and the 292 category of plastic products industry.First, manufacturing is interpreted as "this category comprises 13 to 43 categories, refers to the physical or chemical change after a new product, whether it is power machinery manufacturing, or Handmade; and whether the product is sold wholesale or retail, are regarded as a variety of manufactured goods and parts in building production should be as for manufacturing, but in the pre construction site are the main components of products, assembly, warehouse equipment, railway bridges and highway, elevator and elevator, pipeline equipment, water equipment, heating equipment, ventilation equipment and air conditioning equipment, lighting and wiring assembly activities, and building the device are listed for the construction and manufacturing the categories include mechanical and electrical products, the scrap auto parts, engineering machinery, machine tools and other batch production process of professional repair, remanufacturing production Products to achieve the same quality and performance as the new products".

- Q: What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- Ji'nan high tech Development Zone, Xin Ruichang machinery mold factory specialized in processing all kinds of plastic products, the company covers an area of more than 30000 square meters, hundreds of employees, the company has owned injection molding workshop, mold manufacturing workshop, foam tooling workshop, assembly workshop covers an area of 10000 acres, the company currently has 3300 tons, 1800 tons, 1300 tons, 1000 tons other large and small injection molding machine more than 20 Taiwan, a maximum of 30000 grams of plastic products production and processing,

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

Send your message to us

PVC Fiber Reinforced Hose Machine Extrusion Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches