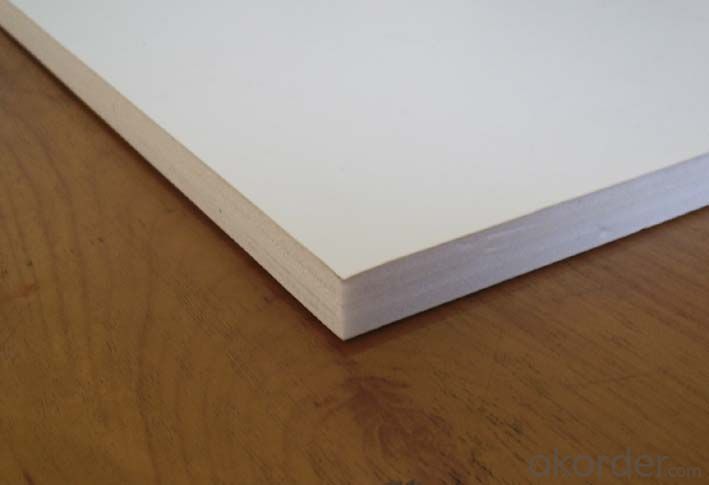

PVC plastic sheet for building materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Our PVC Foam Board/Sheet Size:

Width: 1250mm-2050mm, 2050mm in max

Length: Any length

Standard size:1220*2440mm, 1560*3050mm, 2050*3050mm

NOTE: we can make other size according customer requirment

| Payment | L/C,T/T,Western Union, MoneyGram, Paypal |

| MOQ | 50PCS |

| Delivery | 6-10days after confirm your order |

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

- Q: Are plastic sheets resistant to discoloration from sunscreens?

- No, plastic sheets are not generally resistant to discoloration from sunscreens.

- Q: How do plastic sheets handle drilling and cutting?

- Plastic sheets are generally easy to drill and cut due to their malleable and lightweight nature. However, the specific handling of drilling and cutting plastic sheets may vary depending on the type of plastic being used. It is important to choose the appropriate tools and techniques to ensure clean and precise cuts, as excessive force or improper methods may cause cracking or damage to the plastic.

- Q: im looking for a scrapbook with paper sheets, no plastic. my idea is to glue down envelopes for my wedding guest book where they can add notes in it. obviously, the plastic lined ones wont do, and i need one with just paper sheets, kind of like a portfolio. any idea of where to find one? ive looked at michaels and they dont have them. Thanks!

- www.okorder / ... Wire bound albums are generally the ones with just paper pages. Originally they were widely available in 10 x 10... Not so much anymore. Cute idea! Good luck!!

- Q: I would like it to be something around the house or not to spendy! thanks

- Maybe a piece of glass like off of an old picture idk

- Q: I need to find some sort of plastic that isnt crazy expensive but strong enough to have people stand on and be able to see threw. Kind of like a bridge, thats transparent.

- Heavy Duty Plexiglass

- Q: Afternoon!I'd like to make some patches which are printed directly onto plastic, which can then be backed with heavy duty velcro. Rather than credit card type width think more along the lines of a thin mouse-mat, but with velcro replacing the foam.Is this something that I can do from home with any deal of realism?Would I need to print onto the surface and then finish it in some way after?If there is some sort of online resource for this and you would be so kind as to link me I don't mind researching, I'm just only able to see printing to credit cards in my searches.Many thanks for any help!

- That's a job best done by a professional printing company as they have the VERY expensive equipment to print ontp plastic, then add a suitable backing. it's not something that you could do with equipment on a size and budget to have at home

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are commonly used as a cost-effective and easy-to-install option for temporary or low-traffic areas. However, it is important to note that plastic sheets may not be as durable or long-lasting as other flooring materials, and their suitability for specific applications should be assessed based on factors such as foot traffic, moisture resistance, and desired aesthetic.

- Q: Are plastic sheets resistant to bending during installation?

- Yes, plastic sheets are generally resistant to bending during installation. They are designed to be flexible and pliable, allowing for easy installation and shaping to fit various surfaces. However, the level of resistance may vary depending on the thickness and composition of the plastic sheet.

- Q: Can plastic sheets be used for point-of-purchase displays?

- Yes, plastic sheets can be used for point-of-purchase displays. Plastic sheets are a versatile material that can be easily shaped, printed on, and customized to create eye-catching displays for products in retail environments. They offer durability, transparency, and flexibility, making them an ideal choice for showcasing merchandise and attracting customers at the point of purchase.

- Q: Can plastic sheets be used for electrical circuit boards?

- Yes, plastic sheets can be used for electrical circuit boards. They are known as flexible printed circuit boards (PCBs) and are commonly used in various electronic devices due to their lightweight, flexibility, and cost-effectiveness. However, plastic PCBs are usually limited to low-power applications and are not suitable for high-performance or high-temperature environments.

Send your message to us

PVC plastic sheet for building materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords