Food Processing Conveyor Belt Food Grade Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

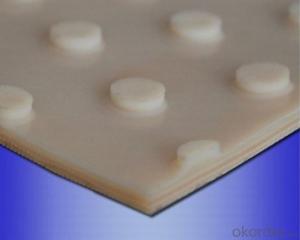

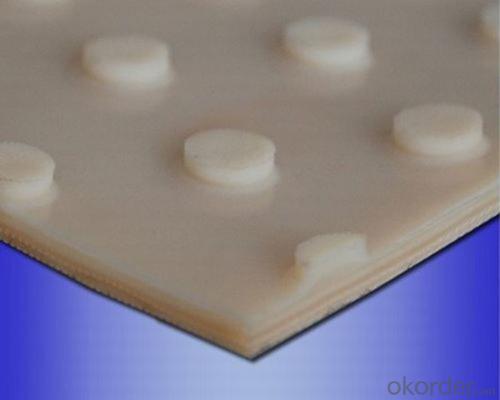

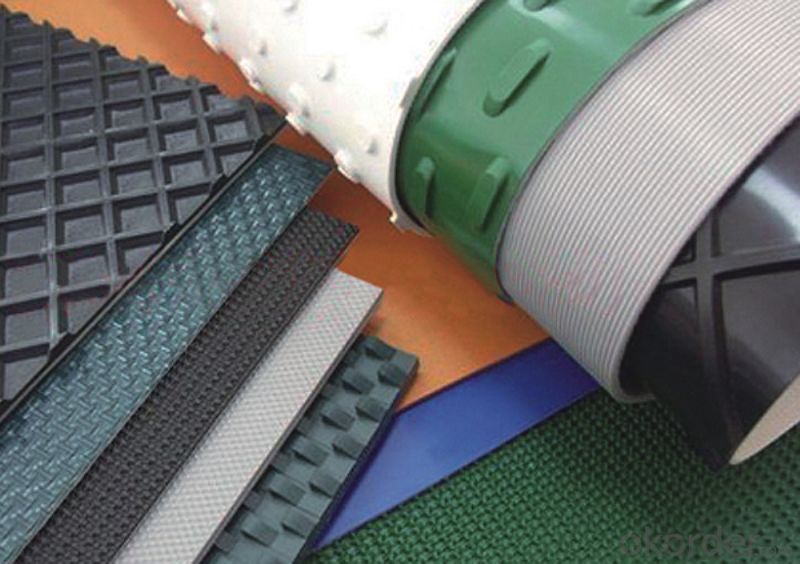

Food Processing Conveyor Belt

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: How long do olive nets typically last?

- Olive nets typically last for several years, with proper care and maintenance.

- Q: Do olive nets require any special storage conditions?

- Yes, olive nets require special storage conditions to maintain their effectiveness and longevity. They should be stored in a cool, dry place away from direct sunlight to prevent damage from UV rays. Additionally, it is crucial to keep them away from any sharp objects or chemicals that could potentially cause tears or deterioration. Proper storage will help preserve the quality and lifespan of olive nets.

- Q: Can olive nets be used for olive tree trunk protection?

- No, olive nets are typically used for harvesting olives, not for protecting the trunk of olive trees.

- Q: How to make up the holes in the plastic basin, and the method is simple and durable

- If it is a small hole, the plastic wrap can be rolled into a bar through the hole, and the two ends of the film can be boiled and pressed around the hole.

- Q: How many grades are there in the plastic block? How to divide?

- Flame retardant grade bottom HB:UL94 CSA and C22.2 No 0.17 standard, requirements for 3 to 13 mm thick sample, the burning rate is less than 40 mm per minute; less than 3 mm thick sample, the burning rate is less than 70 mm per minute; or extinguished in 100 mm signs before.V-2: the flame was extinguished in 60 seconds after the two and 10 second combustion test of the sample. A fire can fall off.V-1: the flame was extinguished in 60 seconds after the two and 10 second combustion test of the sample. No fire can fall.V-0: the flame was extinguished in 30 seconds after the two and 10 second combustion test of the sample. No fire can fall.

- Q: How do olive nets affect the development of olive tree trunks?

- Olive nets protect the development of olive tree trunks by providing a physical barrier that prevents damage from external factors such as pests, birds, and harsh weather conditions. These nets shield the trunks from potential harm, allowing them to grow and develop undisturbed. Additionally, olive nets can also aid in maintaining the overall health of the tree by reducing the risk of diseases caused by pests or weather-related damage.

- Q: Are olive nets suitable for olive tree grafting from rootstocks?

- No, olive nets are not suitable for olive tree grafting from rootstocks. Grafting is a delicate process that involves joining a scion (the desired variety) with a rootstock (usually a hardy and disease-resistant variety). Olive nets are typically used for harvesting olives by preventing them from falling to the ground and getting damaged. They are not designed or effective for supporting or protecting grafts during the grafting process.

- Q: Can olive nets be used in conjunction with other harvesting methods?

- Yes, olive nets can be used in conjunction with other harvesting methods. Olive nets are commonly used to collect olives that are knocked off the tree during mechanical harvesting methods such as shaking or using mechanical harvesters. They help gather the olives efficiently and prevent them from falling to the ground. Additionally, olive nets can also be used alongside traditional hand-picking methods to catch any olives that may drop during the process, ensuring a thorough harvest.

- Q: Is PC the same as plastic?

- This leads to the appearance of it is easy to scratch, PC material is a Han Dynasty atlas, but its strength and good toughness, regardless of weight or general beat, as long as you're not trying to hit it with a stone, it is enough to longevity.

- Q: Are olive nets suitable for both traditional and modern olive farming practices?

- Yes, olive nets are suitable for both traditional and modern olive farming practices. Olive nets are used to collect falling olives during the harvest season, whether they are manually shaken from the trees or mechanically harvested. This method is common in both traditional and modern olive farming practices, making olive nets a versatile and effective tool for olive farmers.

Send your message to us

Food Processing Conveyor Belt Food Grade Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords