PVC Ceiling Wood Corner Polokwane - PVC Gypsum Ceilings with Back Aluminium Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Normal width:1.48M,1.53M,1.83M,2.0M. 2.35 M, 2.5 M

Translucent Film: Max Width 4.0M

Length: 100 M or 150 M per roll , can be customized

Light Weight:200-300g/M2

Guarantee: 10 years

Fire rating: B1 (Chinese Standard)

Tension: Withstand tension of 185kg per square meter

1 Rich color

Nine series and over hundred colors are available

2 Strong modelling function

the stretch ceiling is a kind of film structure material , deciding ceiling’s whole style according to curving shape of the keel ,,so it styles freely with diversification . Large -scale usage will surely comes to simple smooth interior effect .

3 Convenient installation

The ceiling can be directly installed on wall , square timber, steel structure, gypsum inter-wall and timber inter-wall , suitable for each kind of construction structure , and can be re-disassembled .

4 Fireproofing feature

M-color ranks B1 fireproofing standard , the same with plaster tablet ceiling

5 Energy saving function

Manufactured with PVC material , the ceiling is provided with excellent insulation function , which lowers the loss of interior temperature to save energy .

.

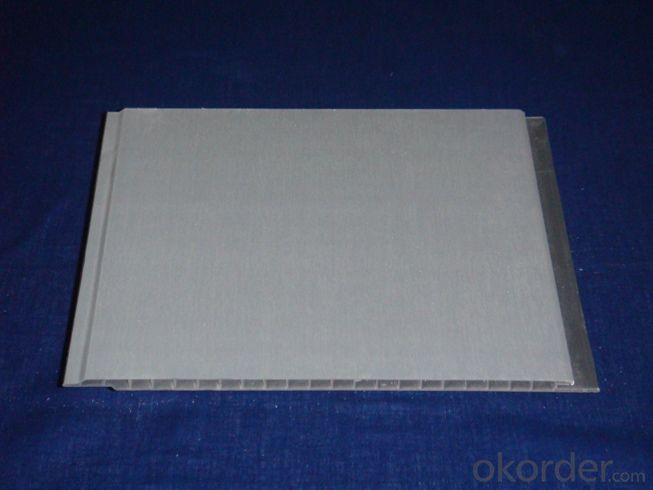

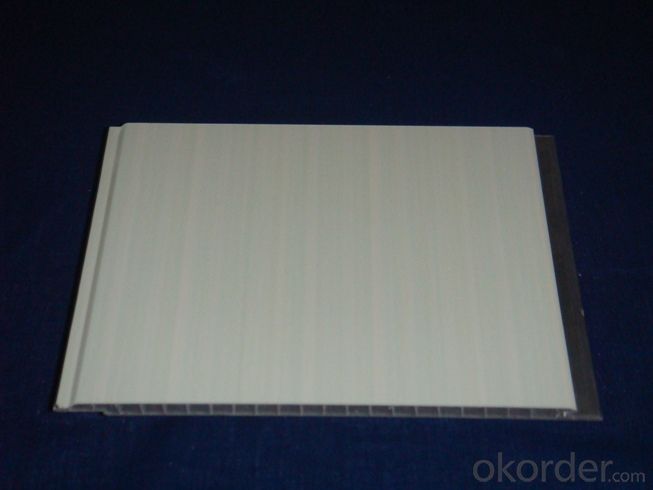

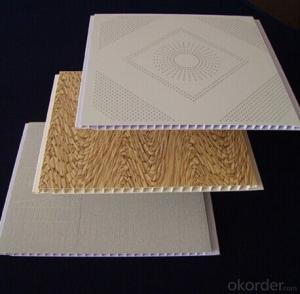

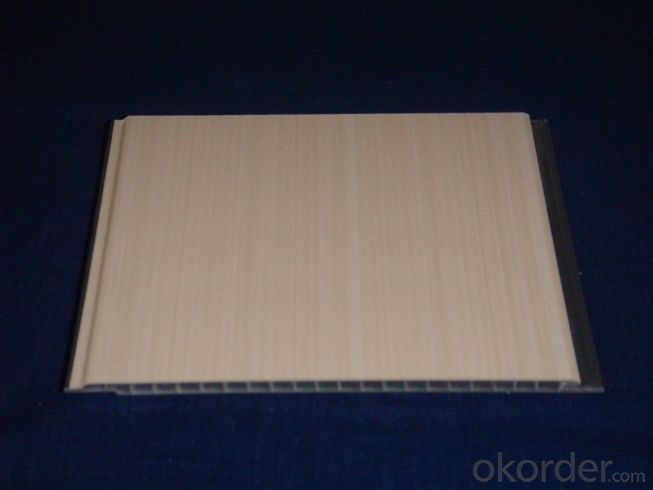

3.Image

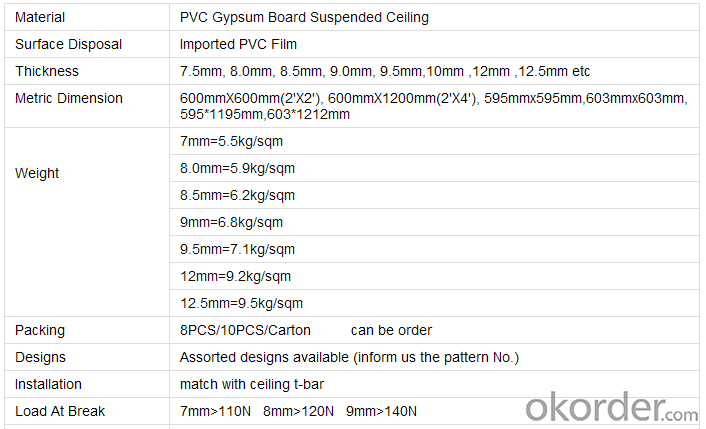

4.Detailed Specification

5.FAQ

Applications

It can be designed with different sizes and styles, widely used for interior ceiling decoration.

Trust us from heart cooperation

Reasonable price

Unique quality

Schedule delivery on time

Updated technology and equipment

Service warmly

1) Commercial & good for decorative

2) Flexible suspension system makes each ceiling tile easily installed and disconnected

3) Easy to match lamps or other ceiling parts

4) Many different pattern

5)PVC film & Aluminum foil back , moisture proof

- Q: Pvc floor and floor leather is the same?

- Must not be the same

- Q: Cottage ceiling with a pvc board can hang ceiling fan?

- No, you must open the hanging to the original structure

- Q: Shop on the ground PVC plastic plate soft PVC or hard PVC?

- PVC flooring is generally divided into commercial flooring and sports flooring. Commercial flooring is generally harder than sports floor. Commercial flooring in the hospital, shopping malls, ships, car lights with more places. Sports flooring is generally relatively soft, usually used in a variety of venues, such as badminton courts, table tennis, basketball, tennis, volleyball and other venues. Floor flexibility is moderate. Athletes fall to the ground will not be injured. You can refer to the TST brand PVC floor.

- Q: How to paste the pvc board to the wall

- How thick is it? First glue glue, and then nail fixation.

- Q: How to print on the PVC board, there must be a production process Oh, I have a engraving machine, you can carve PVC board, but do not know how to screen printing

- Need to have a screen ink scraping gum and the like I can give you technical support

- Q: Pvc plastic plate afraid of the sun?

- PVC ceiling generally add 200 copies of calcium, plus they do not profit, buy back the kind of film with the next.

- Q: Pvc foam board and wood-plastic plate difference?

- Wood-plastic board generally add wood for the powder or bamboo powder, rice bran, etc., there are some wood-plastic plate which has added foam agent. Foam plate section with holes, the density is light

- Q: If you use PVC board to be a simple cylinder, then there is a piece of mouth that piece, how can we avoid it?

- With the injection molding process! It will not happen

- Q: How a pvc board made a convex surface

- Hot press, or after heating with the convex mold you want to do, but generally heated to 90 degrees or so can

- Q: What is the PVC board and KT board, what are the specific role?

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

Send your message to us

PVC Ceiling Wood Corner Polokwane - PVC Gypsum Ceilings with Back Aluminium Foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords