PVC Ceiling Tile - Hot Laminated PVC Gypsum Ceiling Tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling) Description

PVC gypsum ceiling tile is made of high quality paper-faced gypsum board with a layer of PVC on surface and aluminum foil on its back. It is a kind of environmental friendly, light weight, high quality, fireproof, waterproof and corrosion-resistant decorative ceiling board.

2,Main Features of the (PVC Ceiling)

Length(mm) | Width(mm) | Thickness(mm) | Edge |

595 | 595 1195 | 7.0 8.0 9.0 | Covered / Non-covered |

600 | 600 1200 | ||

603 | 603 1206 | ||

605 | 605 1210 | ||

TRUSUS pvc gypsum ceiling tile is available to be produced the thickness from 7.0-12mm, the design according to customer requirements,Both Metric and Imperial systems are accept | |||

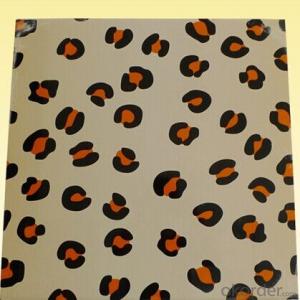

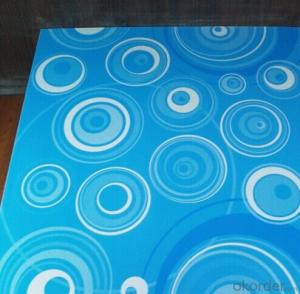

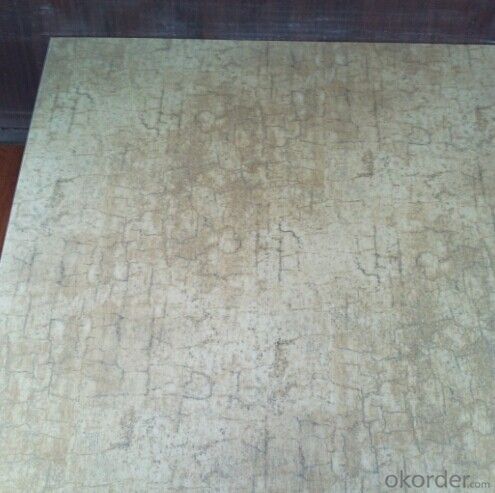

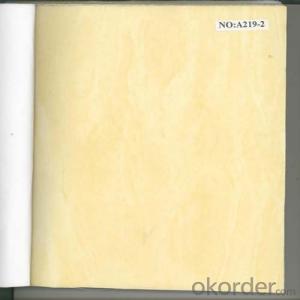

3,(PVC Ceiling) Images

4,(PVC Ceiling) Specification

Materials | Gypsum Board |

Surface | PVC and Aluminum Foil |

Allow Dimension Difference | Length ≤±2.0mm |

Weight Kg/m2 | Width ≤±2.0mm |

Thickness ≤±0.5mm | |

< 6.5kg/m2 | |

Strength | Break Load>150N |

Containing Water Rate | < 1% |

Fireproof Class | Class B1 Meet the standard:GB8624-1997 |

Moisture Requirement | Under 90% |

5,FAQ of (PVC Ceiling)

Other companies claim their tiles/panels are washable (only temporarily) and some even claim to be waterproof, but only our tiles can be washed over and over, even a million times, and never be damaged. They are completely waterproof, will never grow mold and will never sag, bow, or bend due to humidity. They have a Class A flame spread and smoke developed index that's approved for all commercial kitchens and dining areas and can be used in any standard grid for drop ceilings. They are very decorative (not industrial looking) and are perfect for not only kitchens but offices, warehouses, food processing plants, clean rooms, bottling plants, and gymnasiums. Too numerous to name them all, so basically anywhere there is a drop ceiling our tiles will work great.

- Q: Laser cutting can cut PVC board

- Can cut, but the general manufacturers are not recommended to cut PVC, will produce toxic gases.

- Q: Metal and PVC board how to use what bonding

- Universal glue, glass glue

- Q: Why do some people tell me when there is a lot of scratches on the color of the polished surface.

- He is the length of the polishing time is okay, mainly due to the properties of the PVC board, coupled with the uneven polishing caused by the use of paint, the problem is the high cost of spray points, local details can be manually manual painting, remember Do not use the ingenuity, too time, the amount is less, very durable!

- Q: Ordinary pvc board can heat moisture it?

- PVC board for the family to choose the economy The most common and cheapest ceiling material. It's PVC as raw material, light weight, waterproof, moisture, moth. As a result of the production process to add a flame retardant material, the use of safety. PVC board a variety of types of colors and patterns, imitation mostly plains, but also patterns, imitation marble pattern. Honeycomb network structure, its cross-section, both sides of the mouth and the shape of the mouth. Such materials should be noted that the choice of surface should be free of cracks or scratches. I should be straight, every mouth is smooth, there is no ups and downs and the local phenomenon of the height difference. The sheet can be bent, elastic, and the hand is percussed with a crisp sound of the surface without sinking a certain amount of pressure. Its shortcomings are poor resistance to high temperature performance, warm environment for a long time easy to deformation.

- Q: Pearl board pvc board distinction

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: What is the difference between acrylic and PVC?

- Acrylic transparency is relatively high, but not impatient, not resistant to solvents and so on ? Acrylic, also known as PMMA, plexiglass and other engineering plastics PVC is PVC, is a general plastic.

- Q: I had a high-efficiency furnace installed in March of this year. Today I noticed water leaking from a section of the pvc exhaust pipe (which travels upward from the furnace, across the ceiling, and out of basement wall where it vents into my backyard). To be more specific, the pipe that comes out of the unit is attached to this leaking section, which is attached to a pvc elbow, then another piece of pipe, and so on. The water is coming from the top of the leaking section. I don't see any of the blue cement the installers put on the other sections. What could this be caused from? Is there an easy fix?

- Put a level on pipe to be sure it`s sloping towards outside! It could be condensation, to repair, cut before and after leaking section, rebuild same as whats removed and replace with 2 collars. (dry fit) put it all together and in place, to be sure it will work, before gluing.

- Q: What kind of material to do the best cleaning station, pvc board waterproof it

- The panel of the rinse table is made of marble or tempered glass. PVC plates are not recommended

- Q: I live in a condo, and ive notived theres some kind of pvc piping slightly protruding from above the ceiling in the shower. this pipe occasionaly drips water. not alot, but definitly enough for me to see it and hear it, and take notice. Is this a problem with the above neighbors living above me? what exactly is the purpose of that piping? sorry for the vague description, but i dont know how else to describe it. help is appreciated.

- 1. you should not see exposed pvc pipe in your condo. If you own the condo, I would report this to the association. 2. The leak could be sweat from the pipe, not likely though. 3. It would hard to fix because right now you haven't a clue who the pipe belongs to.

- Q: Andy board and KT board What is the difference

- PVC foam board, also known as snow Fu board and Andy board

Send your message to us

PVC Ceiling Tile - Hot Laminated PVC Gypsum Ceiling Tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords