PVC Foaming Plastic-Wood Profile & Sheet Plastic Sheets Plastic Window & Door Profile Extrusion Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

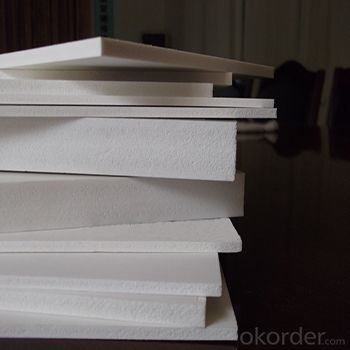

pecifiation of PVC foam board can be produced by our PVC foam board machine:

Width: 915mm to 1830mm

Thicness: 1-33mm

Density: 0.45-0.9g/cm3

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Production flow of PVC/WPC foam board:

Material batching mixing_extruding_molding_vacuum calibrating and cooling_hauling_cutting- final WPC foam boards

Popular Surface treating ways:

- lamination

- hot stamp printing

photos:

- Q: Hi, I bought a devco fireworks cake, never shot one before. It comes packages with a think plastic covering the whole thing, however the fuse can be accessed by lifting a little tab.Obviously seems easy enough, but I'm wondering about the transparent plastic covering on top... seems that will stop the rockets from firing up no?

- yes!! remove the plastic and the red paper that covers the business end for the best effect.

- Q: At the end of my dentist appointment, my dentist asked to bite down hard on this black sheet of rubber or plastic and then he would pull it out.

- Sounds like he was using articulating paper. You bite on it and it leaves a colour (usually red or blue) on the teeth were they touch the opposing teeth. If your dentist has just done a filling for example they will check that they have not altered your bite by propping your mouth open or allowing no contact to be made, as both of these situations will cause problems. However if if was a rubbery mixture in a tray which was inserted over all your teeth and you were asked to bite into it, he was taking impressions. If your still unsure just ask, im bet he will be pleased to tell you hope this helps :-)

- Q: There is extreme wetness near the base of the walls 1 perticurally to the south and west and one to the north and west sides. I have had the attic ventilation balanced and it has gotten a little better. I also forgot that there is tyvek on the exterior and the cedar siding is curving toward the outside. I had the worst of it (siding) replaced this summer. The heat registers have just been replaced because they were rotted. I am replacing a sliding door for the same reason. I am also trying to replace some windows that may be leaking air. Thank you

- HERE IN SE, TX WE HAVE HUMIDITY ALL THE TIME AND WE DO NOT PUT PLASTIC UNDER THE SHEETROCK THE ORDER FROM INSIDE TO OUTSIDE IS PAINT SHEETROCK WALL STUDS WITH INSULATION BETWEEN THEM OSB(OUTSIDE SHEATHING BOARD) TYVEK SIDING PAINT OR STAIN THATS IT. USING THE PLASTIC U HAVE CREATED THAT VAPOR NOT A VAPOR BARRIER. THE TYVEK DOES THAT JOB THE HOUSE IS SWEATING BECAUSE OF THE DIFFERENCE IN THE TEMP INSIDE TO OUTSIDE. THE FUTURE HEALTH ISSUES ARE MOLD AND DECAYING SHEETROCK

- Q: Maybe 48in X 48in

- Try a local art/craft store and look for clear acetate sheets. For larger pieces look in the phone book for plastic suppliers or similar. Most of them will sell to public. Home centers have clear acrylic but it may be thicker than what you need.

- Q: Are plastic sheets resistant to warping or shrinking under heat?

- Yes, plastic sheets are generally resistant to warping or shrinking under heat, as they have a high melting point and can withstand elevated temperatures without deforming. However, it's important to note that the exact behavior of plastic sheets can vary depending on the specific type of plastic used and the intensity and duration of the heat exposure.

- Q: I have a concret fish pond. like to use plastic sheet as liner. I like to bond them togeter.

- Buy some clear cement adhesive. Use in standard caulk gun. This stuff works very well but clean cement first with a good cement cleaner and for really bad stains/spots use muratic acid and flush off completely, then dry good from sun. I am not real positive this adhesive will come in clear and if not the adhesive may show through. You may have to buy it by the can and brush it on.

- Q: Can plastic sheets be used for architectural applications?

- Yes, plastic sheets can be used for architectural applications. They are commonly used for various purposes such as roofing, cladding, insulation, and glazing in buildings. Plastic sheets offer advantages such as versatility, durability, lightweightness, and cost-effectiveness, making them suitable for architectural designs and construction projects.

- Q: I have to do environmental poster for a class and wanted to know how thick the sheet of plastic is.

- very

- Q: What drill is good for punching plastic sheets?

- Plastic drill, twist drill is good. Although the PVC plate is plastic, it is very hard to drill. Drilling with carbide drills is efficient and the drill is durable.

- Q: Are plastic sheets suitable for DIY greenhouse construction?

- Yes, plastic sheets are suitable for DIY greenhouse construction. They are lightweight, affordable, and provide excellent insulation and transparency for sunlight. Additionally, they are easy to work with and can be cut to fit any desired shape or size.

Send your message to us

PVC Foaming Plastic-Wood Profile & Sheet Plastic Sheets Plastic Window & Door Profile Extrusion Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords