2 X 2 PVC Ceiling Tiles - High Density PVC Foam Board for Multiple Applications / Professional Manufacturer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

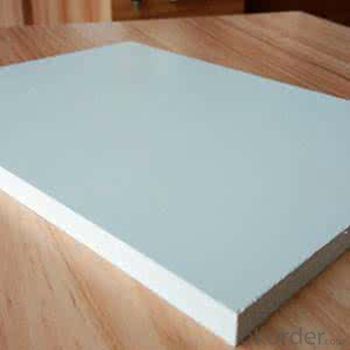

PVC Foam Board

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

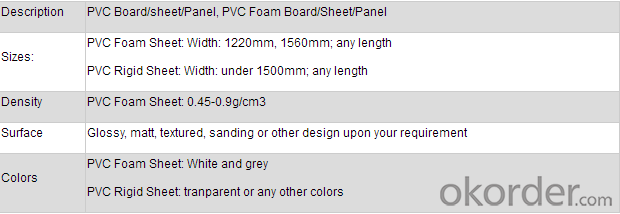

2.Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

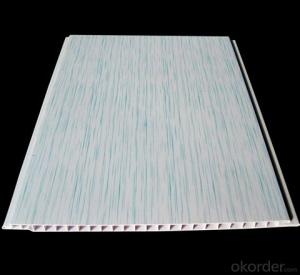

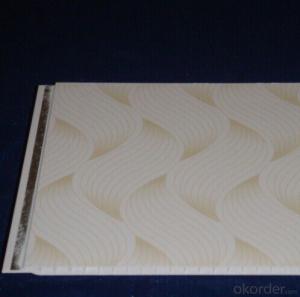

3.Pictures

4.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

5. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf.

(3) Transportation: steamboat, airplane, train carriage, roof and carriage inner layerand other industry.

6.FAQ

1, How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect.

2, Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

3.What factors affect the price?

Answer: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to

get exact quotation.

- Q: Seeking a variety of engraving machine commonly used board specifications like a two-color plate is 1200 * 600 for other specifications Thank you

- 2.4 m x 0.35 m x 2.0 cm 2.4 m x 0.30 m x 2.2 cm 2.4 m x 0.35 m x 2.0 cm 2.4 m x 0.30 m x 2.2 cm

- Q: PVC wood-plastic board Saw cut out of the board is not rectangular, sometimes parallelogram is sometimes how to adjust the trapezoid

- Can not be directly by hand to the rotation of the saw blade next to the object, if necessary, can be used to other long auxiliary materials to open and then take.

- Q: Pvc board how to install curved curtains

- Bending and straight rail installation is the same way, ah, to the time are straight, but according to the size of the scene is the current curvature of the bend, the installation code is similar.

- Q: What is the difference between an integrated ceiling and a PVC ceiling?

- Integrated ceiling: HUV metal plate and the combination of electrical appliances. Sub-board module, heating module, lighting module, ventilation module. With the installation is simple, flexible layout, easy maintenance, a bathroom, kitchen ceiling of the mainstream. Today, with the growing development of the ceiling industry, balcony ceiling, restaurant ceiling, living room ceiling, aisle and so on are gradually becoming the mainstream of home improvement. In order to change the monotonous lack of ceiling color, integrated art ceilings are becoming the market trendy. PVC gusset ceiling: the PVC resin as the base material, adding a certain amount of anti-aging agent, modifier and other additives, by mixing, rolling, vacuum blister and other technology made. This PVC gusset ceiling is particularly suitable for kitchen, bathroom ceiling decoration, with a light weight, moisture, heat insulation, not easy to burn, no dust, easy to clean, can be painted, easy to install, low prices. PVC buckle ceiling pattern more varieties, to choose from the varieties are: milky white, beige, lake blue, etc .; patterns are: Epiphyllum, flat peach, Xiong Zhu, Yunlong, grid flowers, parquet and so on. May require the production or distribution unit to produce its inspection report, and should pay special attention to whether the oxygen index is qualified, it must be greater than 30, is conducive to fire. And then according to the installation of the place and personal hobbies and environmental coordination and other factors, to select their own room decorated with decorative patterns.

- Q: Pvc board can not be posted on the wallpaper, can be used to how long

- Yes, but this material should only use self-adhesive

- Q: Pvc floor green? Can you pave it in the bedroom?

- First, the plastic floor can not be used outdoors. The reason for using in public places is not because the floor is not environmentally friendly, but the plastic floor is more wearable. Secondly, in terms of environmental protection, some domestic flooring, although the environmental protection standards of Europe and the United States, but more environmentally friendly than to strengthen is sure. The golden mouse floor is nice. If the economic strength to allow, then choose to import better.

- Q: Is ABS a board with PVC?

- PVC material is a kind of plastic decorative materials.

- Q: Acrylic board, Abs board and PVC board What is the difference, which can be cut with electric wire?

- The acrylic sheet is a polymethyl methacrylate (PMMA) sheet plexiglass. It is widely used in instrumentation parts, car lights, optical lenses, transparent pipes and so on The Abs plate is an acrylonitrile / butadiene / styrene copolymer plate. Widely used in food industry parts, building models, Shouban production, into the electronic industry components, refrigerator refrigeration industry, electronic appliances, pharmaceutical industry, auto parts and so on. PVC board is a vacuum plastic film. Widely used in chemical, oil, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries.

- Q: PVC ceiling plate how to disassemble

- First of all, you have to observe the buckle board, the general edge of the last piece is not a block, then this piece is not the whole piece is the last piece, but also to first remove a piece, Hold down the last piece of the hand to the wall hard push, to 2 side to push, light push side is not enough, you push this piece in the end, you will find and another side of the office has been divorced, and then You can directly win, and the second plate will remove the screws, the screws in the middle of the wood, directly screw down on it, the screw down and then pull down this board also down, and then Repeatedly, the top is removed!

- Q: Installed when the ceiling is not buried hood smoke pipe, now need to demolition of the roof buried, but do not know how to tear down, wait for the master pointing maze. The key to the problem is to know which is the last piece, but do not know how to start

- To find a less prominent position which can be any, if the time may be aging for a long time, when the demolition of the point will be broken.

Send your message to us

2 X 2 PVC Ceiling Tiles - High Density PVC Foam Board for Multiple Applications / Professional Manufacturer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords