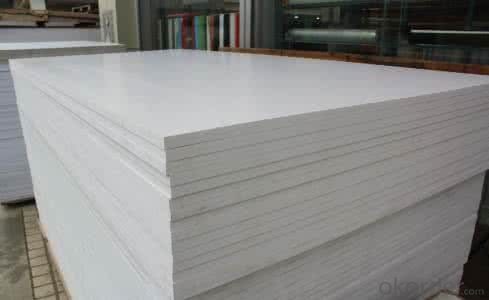

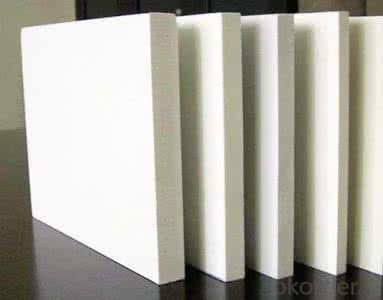

Plastic Sheets PVC Foam Board Production Line / Hard Surface PVC Foam Sheet / Polystyrene Foam Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC foam board production line/hard surface PVC foam sheet/polystyrene foam board

Product Descriptionion

Overview

__________________________________________________

Specification

| Place of Origin | Zhejiang,China | Thickness: | 1-20mm |

| Material: | PVC | Product name: | PVC Foam Board |

| Color: | White | Application: | Sign & Decoration |

| Feature: | Eco-friendly | Certificate: | SGS |

_______________________________________________________________

Packaging & Delivery

Packaging Details:PE bag/ carton /pallet

Delivery Detail:20 days after deposit

——————————————————————————————————————————

PVC foam board production line/hard surface PVC foam sheet/polystyrene foam board

PVC Crust Foam Board is easy to clean and maintain, a good deep-drawing quality, light weight, but strong. PVC Foam Board is organic and inorganic combination of the preparation through the series of advanced technologies, the extrusion foam molding, a wood-plastic sheet, extrusions, bar. As the use of the raw materials and production processes do not use glue bonding, no formaldehyde, benzene, ammonia, trichloroethylene, and other harmful substances. And has anti-UV, coloring good performance, heat insulation, noise, acid and alkali resistance, insulation, fire-retardant, anti-corrosion, anti-mildew and anti- pest, moisture resistance, sawing, planing, nails, a good machining performance, and 100% recovery, is a jewel instead of the traditional green timber new material. Compared to PVC free foam board, PVC crust foam board has the better advantages on hardness , cleaning, strength and so on.

——————————————————————————————

FAQ

When can I get the price?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time. It is better to contact us with instance ways, in case of any delays.

Want more further help?

Don't hesitate to send inquiry to us and you will get in-time reply within 24 hours.

You can also contact us with all Instant Messaging Service like Wechat, Whatsapp, Skype, QQ

- Q: Can plastic sheets be used for insulation against electromagnetic interference?

- Yes, plastic sheets can be used for insulation against electromagnetic interference.

- Q: Can plastic sheets be used for agricultural purposes?

- Yes, plastic sheets can be used for agricultural purposes. They are commonly used in agriculture for various applications such as greenhouse covers, mulching, and protective covers for crops. Plastic sheets help in regulating temperature, conserving moisture, preventing weed growth, and protecting crops from pests, making them a valuable tool in modern farming practices.

- Q: well i was just at this weird consert and there was a plastics thingy so im just wondering

- Its to read the song list. Or it might be to read the sheet music to the songs as well. So they know where they play at in the songs, that's why. Good luck!

- Q: PVC how dirty is the plastic board? Can it be cleaned soon?

- Wash with toothpaste and toothbrushBecause it is not a big object, you can simply brush with toothpaste and then wipe it gently until you wipe it. This adds flavor to the purse.

- Q: Moved into a house that has a small bathroom with 4'x8' sheets of tile installed. (Not real ceramic tile, I think plastic?) Can these be painted?

- Anything can be painted, as long as you use the correct paint. You'll need to do a little research to find out what material the tile is made of, and then go to any paint store and ask for the right paint for that material. Some prep work might be needed, like sanding the surface to make the paint adhere, but the store rep should be able to help you with advice if they have any intelligence for that department. ;)

- Q: What's the name of the perforated plastic board for one board?

- Plastic plate drilling with twist drill PVC plate, although the plastic plate drilling wear badly, with carbide drilling, drilling efficiency, drilling durablePlastic drilling tools: punching machine, laser drilling, mechanical and electrical hot wire cutting, drilling and so on

- Q: In the past, I would print on 8.5 x 11 clear plastic sheets (about as thick or a little thicker than paper) using a LasorJet printer and had good results. Except when it was too thin and the heat tended to kind of curl or warp it. Will inkjet printers print on the same material? Or does it have to have some coating?

- Well I ordered what I thought were clear plastic sheets for ink jet printer that would be a big NO the ink did not hold and what did go on smeared at least on what they sent me. I would love to know where I could get printable clear sheets for my ink jet printer.

- Q: Can plastic sheets be used for protective film applications?

- Yes, plastic sheets can be used for protective film applications. They are commonly utilized to protect various surfaces such as glass, metal, or other delicate materials from damage or scratches during transportation, storage, or construction processes. Plastic sheets offer a cost-effective and easily applicable solution for temporary protection.

- Q: will a green house made out of plastic sheets benefit my medical marijuana plants?

- it okorder / sign up and ask away in the growing question.

- Q: I desperately need this material for a project at work, my boss is counting on me. I've already looked at Home Depot (only white stuff), Walmart had nothing, and Michaels had nothing. Any Suggestions???

- I had to look for a Kydex plastic (something cutable with a scissors) and found a plastics manufacturer in our city of Milwaukee who not only was local, they had a walk in store on their warehouse. The store had the benefit of having small pieces of all types of acrylic and plastic for sale, at reasonable prices. Check your phone book under manufactuers or plastics, give them a call and ask if they have a retail store. The scraps I got were good size and only about $4-$8.

Send your message to us

Plastic Sheets PVC Foam Board Production Line / Hard Surface PVC Foam Sheet / Polystyrene Foam Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords