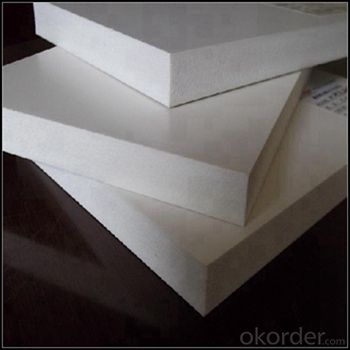

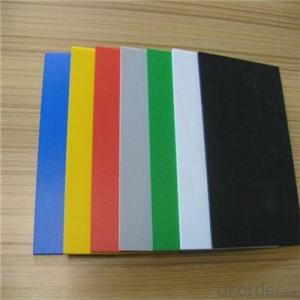

High Density PVC Foam Board Plastic Sheets 1-30mm for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

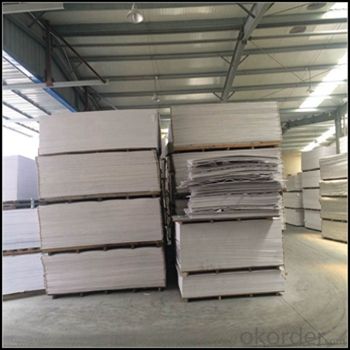

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

a kind of high-tech product, is produced by special machinery and technology processing, has excellent corrosion resistance, insulation, and have a certain mechanical strength. The main material new PVC resin can be foamed and extruded into a special sheet with many advantages and uses wildly. It's a good substitute for wood.

Product Features

•Excellent clarity, transparency and gloss

•Least thickness variation

•Non-toxic

•Smooth die-cutting

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

•Non-sticky

Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Details

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | CMAX |

6 | Certificate | SGS |

7 | Weldable | Yes |

Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

FAQ

Sample: Can I get samples?

Yes, samples are available and can be provided free of charge, customer only need to pay for the shipping cost.

2. Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

Pictures

- Q: The plastic board is brittle at low temperature

- Plastics are polymer materials at room temperature showed a hard and tough, in higher temperature conditions will exhibit toughness even elasticity, once the temperature is reduced to below the glass transition temperature or brittle point, will show the fragility of.

- Q: I must be having a brain fart! I can't remember why I bought six rolls of duck tape and heavy gauge plastic sheeting. I remember that it had something to do with the Y2K scare but what the hell? Can someone refresh my memory, please?

- Save them for a potential n1h1 scare.

- Q: I got a protective plastic sheet, but every time I try to put it on, a million bubbles keep popping out.

- Unfortunately, it's not really possible to eliminate every bubble. Just put it on very slowly and try to rub them out as you go instead of trying to get them all at the end. Keep in mind that when the iPod is turned off, the bubbles look horrible but once it's turned on, you won't notice them nearly as much.

- Q: What are the load-bearing capabilities of plastic sheets?

- The load-bearing capabilities of plastic sheets can vary greatly depending on the type of plastic, its thickness, and the specific application. Generally, plastic sheets can support light to moderate loads, but they may not be suitable for heavy or structural loads. It is important to consult the manufacturer's specifications and guidelines to determine the specific load-bearing capabilities for a particular plastic sheet.

- Q: In home improvement, what is the best material used in the kitchen ceiling, aluminum gusset is good, or PVC plate or aluminum plate?

- Relative to this problem, the aluminum gusset plate does not need to use any wood in the installation process, is more suitable for the moist environment suspended ceiling.

- Q: The balcony with what material decoration?

- PVC ceiling profile of water, scrub resistance is very strong. Available daily use cleaning agents to clean after washing with water; the gap between susceptible to grease, available cleaning brush dipped in detergent scrub, rinse with water; attention to the lighting circuit not wet. If the PVC ceiling profile is damaged, it is very convenient to update. As long as the end of the strip is removed, the plate will be pulled out of the strip and replaced by the new plate. Replacement should be noted that the new plate and the old plate color should be the same, do not have chromatic aberration.

- Q: Do plastic sheets have UV protection?

- Yes, plastic sheets can have UV protection. Some plastic sheets are specifically designed and treated with UV inhibitors or filters to block or absorb harmful ultraviolet (UV) radiation. These UV-protected plastic sheets are commonly used in outdoor applications to prevent UV damage, such as yellowing, fading, or degradation caused by prolonged sun exposure.

- Q: Can plastic sheets be used for picture frames?

- Yes, plastic sheets can be used for picture frames. They are a popular and affordable alternative to glass frames. Plastic sheets, such as acrylic or polycarbonate, are lightweight, shatter-resistant, and offer UV protection. They can provide a clear and protective covering for pictures while still maintaining a sleek and modern look.

- Q: Thanks you guys! You're always so smart!

- It depends on whether this is a mathematics question or a real one that involves actually doing the work. If it's math, then you would cut the piece into 96 1/8 strips and then chop them into 16 3/4 pieces or vice versa, it doesn't matter which you do first. 96 x 16 = 1536. There are 8 strips 1/8 wide in each inch and there are 12 inches in your sheet so 8 x 12 = 96. 12 divided by 3/4 = 16. 96 x 16 = 1536. If this is a real activity, then it depends on the type of plastic you're using and whether you can cut it with a knife or paper cutter because if it's plexiglass you have to use a saw of some sort and you can lose up to 1/8 for each cut due to the teeth of the saw blade. Therefore you would have approximately half as many finished pieces, and you would probably lose half of those because they'd fly all over the shop. Plexiglas is also prone to static electricity and would attract all the dust in the environment and be kind of a beast to do without special acrylic blades. Thin sheets of film could be done with scissors or a paper cutter.

- Q: I want to cover the sofas with plastic sheeting. I have lazyboy type reclining sofas and was wondering if there are special covers or if there is a way of fitting them on?

- Sure they make covers for all types of sofas

Send your message to us

High Density PVC Foam Board Plastic Sheets 1-30mm for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords