double wall corrugated pipe production line high speed big diameter plastic pe pipe product line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

double wall corrugated pipe production line, high speed big diameter plastic pe pipe product line

| Features of plastic pe pipe product line |

1) Optimizing diameter range of pipe production, can produce bigger diameter range with same investment. 2) Smooth and stable operating water cooling system, ensure high speed production. 3) Can replace mould block quickly, to save waiting time. 4) Most intelligent control on water, air pressure and electricity, easy to operation, monitoring and control. 5) Die head with partial wall adjustment function, convenient and easy to operate. 6) Corrugator section with quickly open function, greatly convenient to trouble shooting, equipment maintenance and other operations. 7) Multistage vacuum molding system, easy to forming, stable operation. 8) Central lubrication system. 9) Remote fault diagnosis system (Optional). |

| Factory of plastic pe pipe product line |

1) Engaging in innovating new technology, devoted to research and develop new technology on plastic machinery for decades of years. 2) Combining the world most advanced technology and new material. 3) Excellent skilled workers, especially R&D engineers, technicians with decades of experience in this industry. 4) First-class after sale service, with the most competitive price. |

| Applications of Double Wall Corrugated Pipe |

1) Cable protection pipes 2) Drainage pipes 3) Other special pipes |

| Suitable Material of plastic pe pipe product line |

HDPE, PP, PVC and other polymers |

| Corrugator Section Specification of plastic pe pipe product line | ||||||||||||||||||||||||||||||||||||||||

|

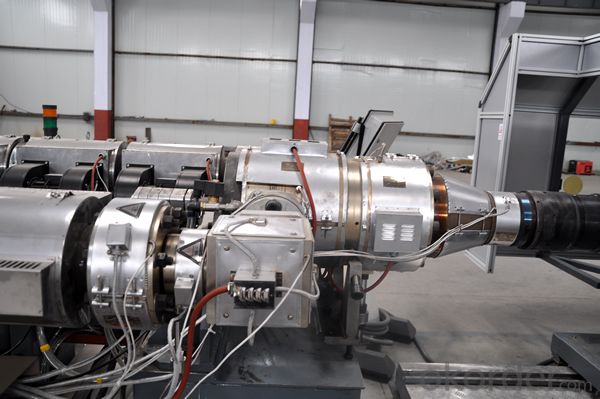

| Detail pictures of plastic pe pipe product line |

Automatic feeder with self-dry function, space saving and efficient. Long effective screw, excellent melting effect.

Shorter die head, low pressure, low temperature, high efficient (patent).

Die head with partial wall adjustable function, convenient and easy to control.

Corrugator with cover, safe. Also with quick open function, great convenient for trouble shooting, maintenance and other operations.

Aviation aluminum mould blocks, very durable and long service life.

Horizontal water cooling system, high efficient and time saving.

Dustless double hydraulic cutter

Automatic unloading device.

Intelligent control on water, air pressure and electricity, easy to operate. Comprehensive protect for all kinds of wire, safe and durable. Touch screen with wireless control handle, very safe and convenient for operating. |

| Samples made by plastic pe pipe product line |

|

- Q: What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q: How many venues will it take? How much does it cost?That's what recycling plastic bottles break. Sell again.What's the machine and how much does it cost? What should be done after breaking? If you make a semi-finished product, you can't sell it wellIs there any profit on this line?

- Small production equipment price corresponding -300 HuaSu Fei Yang machine,I was prepared to PET mineral water bottles by color sorting (bottle, cover ring, trademark, water drop), production processes: sorting - crushing (grinding) - Cleaning - drying - bagging, processing in such a manner as to sell 7! No difference, the corresponding price and production equipment prices are 10000 yuan distinction, processed products sold to the product factory, --1PET mineral water bottles, broken pieces (crushed) and PP material broken fragments (crushed) can be done with the same machine!

- Q: What are the plastic products stocks?

- Provide land, property, equipment, vehicle rental services.TS: domestic major enterprises to focus Plitt production of automotive modified plastics products, key high-tech enterprise of national torch plan. Currently has five series of more than 300 varieties, with an annual output of 50 thousand tons of production capacity, production of automotive modified plastics in the domestic enterprises in the top, the yield of modified ABS, PC/ABS alloy products ranked first, the yield of modified PP products are also in the forefront. The company provides services for automobile manufacturing, household appliances, electronic information and other enterprises, specializing in high performance plastic composite materials research, production, sales and service, is one of the industry earlier for the automotive industry the most complete enterprise qualification.

- Q: Plastic POM POM generally used for the production of what plastic products?

- POM used in the lubrication, abrasion resistance, rigidity and dimensional stability requirements more stringent sliding and rolling mechanical components, the performance is very superior, mainly used for industrial machinery, automobile, electronic and electrical, plumbing and irrigation supplies etc..Pom Pom Pom name (POM) also known as steel, special steel. It is based on formaldehyde and other raw materials for polymerization. POM-H (POM homopolymer), POM-K (polyoxymethylene copolymer) is a thermoplastic engineering plastics of high density and high crystallinity. Good physical, mechanical and chemical properties, especially excellent resistance to friction.POM is a non - chain, high-density crystalline polymer with excellent comprehensive properties.POM is a smooth, shiny hard and dense material, light yellow or white, can be used in -40- 100 degrees C temperature range for a long time. Its abrasion resistance and self lubrication are superior to most engineering plastics, and it also has good oil resistance and peroxide resistance. Very acid free, alkali resistant and UV resistant. (adding UV can greatly improve its ultraviolet resistance rating)

- Q: The manufacturing process of plastic products? Who knows?

- There are 4 categories:1, extrusion molding: in plastic processing, also known as extrusion, in the non rubber extruder processing, the use of hydraulic pressure on the extrusion of the mold itself, said press out. Refers to the material through the extruder, the barrel and the role of the screw, while heating plastic, while the edge is pushed forward by the screw, continuous through the nose and made a variety of cross section products or semi-finished products of a processing method.2, injection molding: also known as injection molding, it is an injection molding method. The advantages of injection molding process is the production of high speed and high efficiency, automation, and more varieties, shaped by the simple, size from big to small, and accurate product size, easy product upgrading, can become a part of complex shape, injection molding is suitable for mass production with complex shape products etc. processing field.3, slush molding: the method is to paste plastic (plastic sol) dumped into the mould is heated to a certain temperature (die or die), close to the cavity wall of the plastic paste is due to heat and gel, and then there will be no cementitious paste plastic and poured out, will be attached to the the cavity wall paste plastic heat treatment (baking), after cooling can be obtained from the mold hollow products.4, blow molding: mainly refers to blow (also called blow molding) refers to the gas pressure in the mold closing type billet hot melt blown to form hollow products, is the third most commonly used plastic processing methods, but also the development of a rapid method of plastic molding. The only female mold mold molding (die), compared with the injection molding equipment, low cost, strong adaptability, capable of forming a good performance (such as low stress), can be formed with complex undulating curves (shape) of the products.

- Q: What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- Recommended Xiangxi inspection, old plastic easy to do, but have no production, proposed to do environmental protection cloth generation.

- Q: PC and PC alloy plastic surface effect which better, which good processing, and what are the other differences?

- The plastic processing of PC alloy PC alloy, in order to improve the mechanical properties of other plastics and the incorporation of PC raw materials, such as PC/ABS, PC/PA, PC/PS and so on, area is PC as a reinforcing agent with other plastics.

- Q: I don't know what kind of machine is needed. How can I sell the material after processing? Is there anyone?I want to make a waste plastic (plastic bottle) small processing at home, I don't know what kind of machine is needed. How can I sell the material after processing? How much money does it cost?. Seek expert advice, the more detailed, thank you!

- This is HDPE's.. PET general crushing cleaning, selling chemical fiber plant, HDPE generally sell granulation plant, cleaning, and some injection molding factory is also useful. Just break it and use a crusher. Crushing equipment from several thousand to twenty thousand or so, some home recycling, there are door-to-door.

- Q: What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- The first said equipment 1 blowing machine 2 printing machine 3 bag making machine 4 mill material if want to make your own words also need about 27000 granulating machine, film blowing machine, printing machine if printing a color around 10 thousand,

Send your message to us

double wall corrugated pipe production line high speed big diameter plastic pe pipe product line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords