Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

1. AUTOMATIC FEEDING SYSTERM

2. ABB BRAND INVERTER

3. RKC BRAND TEMPERATURE CONTROLLER

PE PIPE PRODUCTION LINE EQUIPMENTS FEATURES:

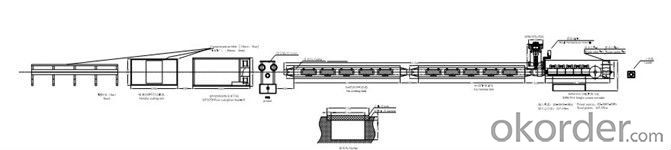

PE pipe production line qingdao benice plastic machinery co.,ltd mainly consists of PE single screw extruder, PE pipe special using mould, PE pipe vacuum calibration water tank, PE pipe drawing machine, PE pipe cutting machine, PE pipe stacker, and the auxiliary machine: SHL200/500 mixer.

PE pipe plastic making machine features:

High speed, high efficiency extrusion single screw extruder is specially designed for extruding PE etc. material, equipped with the lower noise, high speed and hard gear reducer. The Special grooved feeding bush with water cooling system results in increasing compression and filling factors. Specialized screw designs for high output, low melting temperature, good plasticization effection, lower energy consumption.

Spiral diffluence type extrusion die is specially designed for PE extrusion. Unique design of low-pressure inclined flow passage spiral/lattice basket die head, ensures low temperature and high plasticizing extrusion of PE pipes; Special designed die core spiral temperature control, ensures the performance of PE pipes; Multi-layer co-extrusion die offers the advantages of low cost and flexibility of layer structure with different material. it features in easy adjustment and even extrusion, ensures that melting pressure and flux are uniformity, the surface of pipe is smooth and shapely. Skype is benicexiaofei

Plastic PE pipe making machine specifications:

Model | Pipe diameter Range (mm) | Pipe extruder model | Marking- line extruder model | Extrusion speed | Max Output | Total installed power | Dimension |

BAXPEG-50×33-63 | Ø20-Ø63 | BAXSJ-50×33 | BAXSJ-25×25 | 0.3-12 | 120 | 65 | 36 ×2.2 ×2.5 |

BAXPEG-65×33-125 | Ø20-Ø125 | BAXSJ-65×33 | BAXSJ-25×25 | 0.3-12 | 220 | 110 | 56 ×2.2 ×2.6 |

BAXPEG-80×33-160 | Ø63-Ø160 | BAXSJ-65×33 | BAXSJ-30×25 | 0.3-6 | 300 | 150 | 50×2.2 ×2.8 |

BAXPEG-80×33-250 | Ø75-Ø250 | BAXSJ-80×33 | BAXSJ-30×25 | 0.5-5 | 400 | 200 | 52 ×2.2 ×3.0 |

BAXPEG-90×33-400 | Ø160-Ø400 | BAXSJ-90×33 | BAXSJ-30×25 | 0.2-2 | 550 | 280 | 66 ×2.2 ×3.0 |

BAXPEG-90×33-500 | Ø200-Ø500 | BAXSJ-90×33 | BAXSJ-30×25 | 0.1-1 | 700 | 360 | 70 ×2.3 ×3.5 |

BAXPEG-120×33-630 | Ø355-Ø630 | BAXSJ-10×33 | BAXSJ-30×25 | 0.1-1 | 900 | 450 | 72 ×2.3 ×3.5 |

BAXPEG-150×33-1200 | Ø710-Ø1200 | BAXSJ-150×33 | BAXSJ-45×30 | 0.05-0.5 | 1500 | 650 | 80 ×3.0 ×4.0 |

Main Configuration of Plastic Pipe Extrusion Line

Extruder/ Vacuum Shaping part/ Cooling part/ Haul-off Device/ Cutter/ Stirring-up Rack

- Q: The next 5 to 10 years, small workshops waste plastics processing prospects for development?

- China's plastic machinery industry production enterprises are large, most enterprises seriously deviate from the economic scale, production equipment backward, technical progress difficult situation is still serious. But some enterprises grasp the trend of market demand and technical development, through technical transformation effectively seize market opportunities, develop economic indicators of economic scale backbone enterprises begun to take place before the sort of product sales enterprises accounted for about twice the total domestic plastic machinery sales. So far, China's plastic machinery products are still medium, small as the mainstream, production has been in the world for many years.In 2012, China exported 69297 sets of plastic machinery, with a total amount of 1 billion 618 million 868 thousand US dollars, with an increase of 10.5% over the same period of last year, and the growth rate fell by 17.9% compared with 2011. Imports of plastic machinery 10482 units, total 2 billion 126 million 350 thousand U. S. dollars, the number of imports and the amount of year-on-year decrease, of which the amount of imports decreased by 2.4%. The year 2012 presses trade deficit of $507 million 485 thousand, compared with 2011 deficit significantly reduced.In 2013 the number of China machinery import 10052 units, the amount of imports of about $1 billion 820 million, and last year fell by 4% and 15%; exports, total exports in 2013 China machine 135213 units, the export amount of approximately $1 billion 720 million, an increase of 94% and 7% respectively.In the first half of 2014, China imported 4156 injection molding machines, an increase of 63%, and imports amounted to 398 million 650 thousand U. s.dollars, an increase of 18%.

- Q: Consult, small toys, plastic products how to shine? What kind of machine or what kind of abrasives do you need? The swordsman knows to ask for help, if feasible, and to have a heavy score! This toy is made of diamond! It's about three or four centimeters in size! Urgent!

- One is to start from the mold and make the inner surface of the mold smooth!One is starting from the material, to make high light products, first of all, there must be good raw materials, and secondly, to have a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q: this month bought a 180 thousand of the equipment and issued a value-added tax invoices, this sum of money can be deducted? How much deduction?Previously fixed assets are not deductible? Is this a policy that has just been changed this year? What's the tax rate? Thank you!

- Can be deducted from the value-added tax invoices on value-added tax deductible, in addition to the purchase of equipment costs, if there are qualified transport documents, you can also by freight * 7% deduction of input tax

- Q: Method for producing plastic product

- Plastic products generally include plastic batching, molding, machining, bonding, finishing and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing. Key links in plastic processing of plastic products. The various forms of plastic (powder, granular, solution or dispersion) made products or blank of desired shape. As many as 30 kinds of molding method. Its choice is mainly determined by the type of plastic (thermoplastic or thermosetting), the starting form, and the shape and size of the product. Plastic processing thermoplastics commonly used methods are extrusion, injection molding, calendering, blow molding and thermoforming, etc., plastics processing thermosetting plastics generally use molding, transfer molding, injection molding. Lamination, molding and thermoforming are the processes of forming plastics on a flat surface.

- Q: Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: Plastic machinery plastic pellet production process _ particles recycled plastics particles

- 31. The preparation method of granulated antioxidant for plastic processing32. A new technology for producing inorganic filling granules for plastics33, bactericidal plastic particles and processing methods34. Method and apparatus for producing porous aluminum alloy with high porosity through plastic particles35. Use of nanoparticles to form thermoplastic foam in order to control the morphology of the bubble36. The spherical particles are prepared by the plastic melt37. Plastic packaging with micro particle markers38. Rotating cutters for granulate plastic castings39, plastic conductive particles and preparation method thereof40. The method of filling and unloading containers by plastic granular materials41. Method and apparatus for crystallization of adhesive particles, especially PET and PU particles42, a long fiber reinforced plastic particles rolling production device43, waste plastics recycling machine

- Q: What plastic products are made out of machines? Is it an injection molding machine?

- According to the process, there are many kinds of processing equipment, not only the injection molding machine, as well as extruder.

- Q: What method or machine do you want to throw bright?

- Invincible brand plastic polishing system is the United States Grath technology companies after years of carefully designed products. It can easily eliminate all kinds of plastic, acrylic and other materials scratch, scratch marks. It also eliminates the yellowing of transparent plastic products due to long periods of sunlight. Such as:Front and rear headlightThe top of a police car, ambulance, etcAcrylic, window, glass, etc..Contain tools:120V high-speed polishing machine one;2-4 hard foam flip discs;2-4 felt plates;2-3x1 medium hardness foam flip discs;2-3x1 hard foam flip discs;2-3 of felt plates;A box of plastic polishes;1-3 chassis;1-4 chassis;Teaching CDAn instruction manual

- Q: When the engineering plastics in the processing, because it is not often around breaking chip, tool and workpiece, not only affects the working efficiency, but also the workpiece surface galling, do not know can not think of a way from the cutting tool and cutting amount? Who can give me some good advice? Please.

- Angle of feed, generally use 60 degrees bevel angle, the amount of cutting does not exceed 1MM. Also, adjust the cutting speed.

- Q: Where are home plastic products, plastic products for daily use, plastic products processing, plastic products, mold

- You are looking for people to give you the processing mold, is it, then you go to the hook online to find ah, above doing this factory a lot

Send your message to us

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches