Plastic Sheets - PVC Expansion Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Introduction:

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

2. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black,as required

3 .Product usage:

1.Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

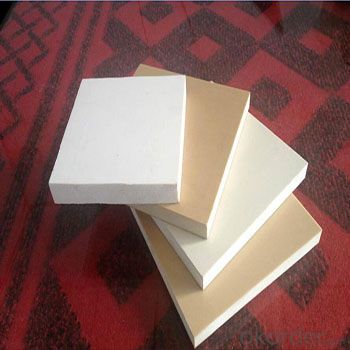

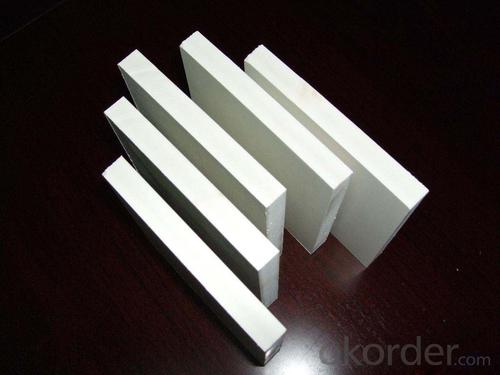

4.PVC foam board pictures:

5 .product features and advantages:

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

6. Product Features:

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

7. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

- Q: You know like 'pexiglas' or what ever. I need Something simular to that. Maybe .5 in or around there for the thickness. What could i Use?

- How large a piece do you need? Could you take a piece of canvas and glue plastic on one or both sides?? Also, you can buy plastic sheets for a bed (to prevent soiling the mattress)--glue some of those together.?? Or glue some tarps together?? Maybe plastic doesn't glue??

- Q: Can plastic sheets be used for window glazing?

- Yes, plastic sheets can be used for window glazing. They are often used as a cheaper alternative to glass and can provide insulation and protection from the elements. However, plastic sheets may not be as durable or transparent as glass, and their longevity can vary depending on the type of plastic used.

- Q: Do you have to use special ink or a special printer to print sheets for an overhead projector?

- Hi there: There are clear sheets of plastic that can be used in photocopiers, laser printers, and inkjet printers. Every major manufacturer of printers has their own Name Brand film supplies which they would recommend, but there are generic sheets that are available in most stationary stores. A few years back there WERE, indeed, special cartridges for printing overheads, since the yellows, in particular were bleached out by the intense light of the projection bulb. Newer inks use pigments and dyes that make the yellows better suited for this application, but you would be smart to outline lighter objects of yellow or faint colours, with a bold line, if you want to make the objects clear on the large screen. The special overhead colored inks would use a yellow that was almost red on paper.

- Q: Any cheap alternatives to the plastic stencil sheets?

- Masonite is too thick to work with. If you're doing street art, you still kind of want to be able to draw like you can with an exacto. Plastic sheeting is good if you want to be able to reuse a stencil. It also rolls up. But cheap poster board works just as well, except that it can fold, which you don't want. You can always go back and cut the plastic stencil from the poster. If you're dead set on the plastic, but can only find 8.5x11, just use clear scotch tape to match the edges. Just make sure the cut outs don't sever the whole seam. Poster board will tear, so let paint dry before you lay them down, and lift them off the painting surface before they dry

- Q: What are the light transmission properties of plastic sheets?

- The light transmission properties of plastic sheets can vary depending on the type of plastic used. Generally, transparent plastics such as acrylic or polycarbonate have high light transmission properties, allowing a significant amount of light to pass through. However, other types of plastics, like PVC or ABS, may have lower light transmission properties due to their opacity or color.

- Q: Are plastic sheets resistant to extreme weather conditions?

- Yes, plastic sheets are generally resistant to extreme weather conditions. They are designed to withstand a wide range of temperatures, including extreme cold and heat, as well as resist damage from rain, wind, and sunlight.

- Q: Do plastic sheets have any insulating properties?

- Yes, plastic sheets can have insulating properties. The insulation ability depends on the type of plastic used and its thickness. Some plastic sheets, such as expanded polystyrene (EPS) or polyethylene foam, are specifically designed for insulation purposes and can effectively reduce heat transfer.

- Q: Can plastic sheets be used for partitions or dividers?

- Yes, plastic sheets can be used for partitions or dividers. They are lightweight, versatile, and easy to install, making them a popular choice for creating separate spaces within a room or office. Additionally, plastic sheets are available in various sizes, colors, and transparency levels, allowing for customization based on specific needs and preferences.

- Q: I need just a few sheets of ABS plastic sheet, about 12X50is there anywhere that sells this for under $50?

- Cheap Plastic Sheets

- Q: What is the minimum temperature that plastic sheets can withstand?

- The minimum temperature that plastic sheets can typically withstand varies depending on the type of plastic. However, most common plastics can typically withstand temperatures ranging from -30°C to -40°C (-22°F to -40°F) without significant damage or deformation.

Send your message to us

Plastic Sheets - PVC Expansion Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords